Feedforward control anticipates disturbances by measuring inputs and adjusting system variables before errors occur, enhancing process stability and efficiency. It differs from feedback control by acting proactively rather than reactively, making it essential in industries requiring precise regulation. Explore the article to learn how feedforward control can optimize your system's performance and reliability.

Table of Comparison

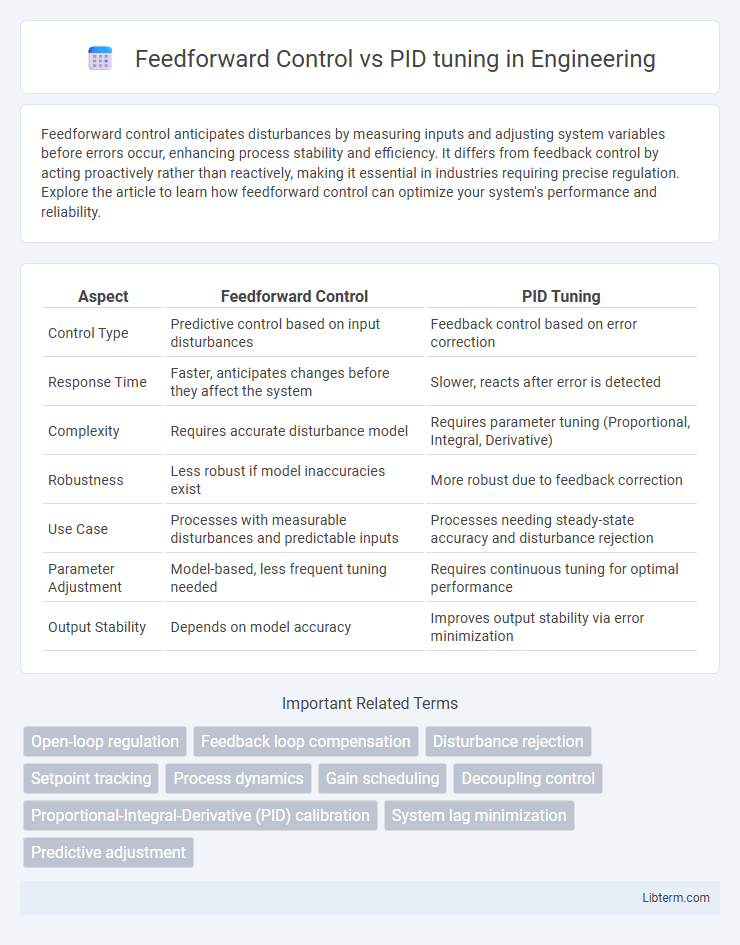

| Aspect | Feedforward Control | PID Tuning |

|---|---|---|

| Control Type | Predictive control based on input disturbances | Feedback control based on error correction |

| Response Time | Faster, anticipates changes before they affect the system | Slower, reacts after error is detected |

| Complexity | Requires accurate disturbance model | Requires parameter tuning (Proportional, Integral, Derivative) |

| Robustness | Less robust if model inaccuracies exist | More robust due to feedback correction |

| Use Case | Processes with measurable disturbances and predictable inputs | Processes needing steady-state accuracy and disturbance rejection |

| Parameter Adjustment | Model-based, less frequent tuning needed | Requires continuous tuning for optimal performance |

| Output Stability | Depends on model accuracy | Improves output stability via error minimization |

Understanding Feedforward Control

Feedforward control anticipates disturbances by using a measurable input to adjust the control output before the process variable deviates, improving system response and stability. Unlike PID tuning, which relies on feedback from the process variable to correct errors, feedforward control proactively counters known disturbances, reducing reliance on error correction. Implementing feedforward control requires accurate modeling of the process and disturbance dynamics to effectively complement PID controllers for enhanced overall performance.

Basics of PID Tuning

PID tuning involves adjusting the proportional, integral, and derivative parameters to optimize system response and minimize error. Feedforward control anticipates disturbances by using a model to adjust inputs proactively, complementing PID feedback control for improved stability. Understanding the basics of PID tuning requires knowledge of how gain settings influence overshoot, settling time, and steady-state error in process control systems.

Key Differences Between Feedforward and PID

Feedforward control anticipates system disturbances by adjusting inputs based on a model, while PID tuning relies on feedback loops to correct errors after they occur. Feedforward requires accurate system modeling for proactive adjustments, whereas PID tuning focuses on reactive error correction through proportional, integral, and derivative parameters. Combining feedforward control with PID tuning enhances overall system stability and response time by leveraging both predictive and corrective mechanisms.

When to Use Feedforward Control

Feedforward control is most effective in systems with measurable disturbances or where the process model accurately predicts output changes, allowing preemptive adjustments before errors occur. It enhances system performance in processes with significant time delays or rapidly changing inputs, reducing reliance on feedback correction inherent in PID tuning. Use feedforward control when disturbances can be quantified and compensated for without waiting for feedback signals, improving response speed and stability.

Situations Favoring PID Tuning

PID tuning excels in processes with unpredictable disturbances or nonlinear behaviors where feedforward control alone cannot compensate effectively. It continuously adjusts control outputs based on error feedback, making it ideal for systems requiring robust stability and adaptability to varying conditions. Industries such as chemical processing and HVAC rely heavily on well-tuned PID controllers to maintain precise regulation despite dynamic environmental changes.

Advantages of Feedforward Control

Feedforward control enhances system performance by anticipating disturbances and making proactive adjustments before errors occur, which reduces system lag and improves stability. Unlike PID tuning that reacts to errors after they manifest, feedforward control relies on predictive models, enabling faster response and minimizing overshoot. This approach is particularly advantageous in processes with measurable disturbances and well-understood system dynamics, leading to improved accuracy and reduced reliance on trial-and-error PID parameter adjustments.

Strengths of PID Tuning

PID tuning offers robust control by continuously adjusting proportional, integral, and derivative parameters to minimize error in dynamic systems, ensuring stability and responsiveness. It adapts to varying process conditions without requiring an explicit model, making it versatile for complex or nonlinear systems where feedforward control may struggle. The automatic correction capability in PID tuning enhances long-term accuracy and compensates for disturbances and modeling inaccuracies.

Integrating Feedforward with PID

Integrating feedforward control with PID tuning enhances system performance by proactively compensating for measurable disturbances while the PID controller addresses residual errors. This hybrid approach reduces overshoot and improves response time by combining the predictive capabilities of feedforward with the corrective feedback of PID algorithms. Implementing feedforward control requires accurate modeling of disturbance dynamics to optimize PID parameters and ensure stable, efficient process regulation.

Common Challenges and Solutions

Feedforward control often faces challenges in accurately modeling system dynamics and disturbance inputs, leading to potential errors if the model is incorrect. PID tuning struggles with achieving optimal performance in processes with time delays, nonlinearities, or varying parameters, causing oscillations or instability. Combining feedforward control with adaptive PID tuning can enhance system response by compensating for predictable disturbances while maintaining robust feedback adjustments.

Real-World Applications and Case Studies

Feedforward control enhances system responsiveness by anticipating disturbances using predictive models, frequently applied in chemical process industries to maintain product quality despite feedstock variability. PID tuning, crucial for regulating dynamic systems in HVAC and automotive sectors, achieves stability and minimizes error through optimized proportional, integral, and derivative parameters based on empirical data or algorithms like Ziegler-Nichols. Case studies in semiconductor manufacturing reveal that integrating feedforward control with precise PID tuning improves throughput and reduces defects by compensating for process disturbances before they impact the system.

Feedforward Control Infographic

libterm.com

libterm.com