Flexural strength measures a material's ability to resist deformation under bending stress, crucial for structural applications where load-bearing capacity is vital. This property helps predict how beams, slabs, and other components will perform under pressure, ensuring safety and durability in construction and manufacturing. Explore the rest of the article to understand how flexural strength impacts your projects and material selection choices.

Table of Comparison

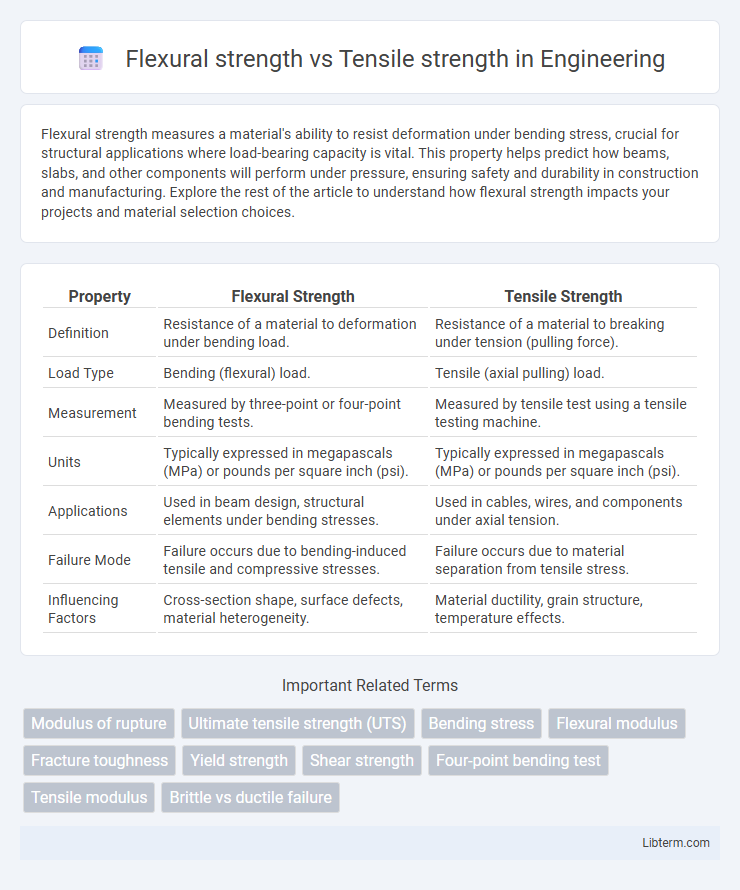

| Property | Flexural Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance of a material to deformation under bending load. | Resistance of a material to breaking under tension (pulling force). |

| Load Type | Bending (flexural) load. | Tensile (axial pulling) load. |

| Measurement | Measured by three-point or four-point bending tests. | Measured by tensile test using a tensile testing machine. |

| Units | Typically expressed in megapascals (MPa) or pounds per square inch (psi). | Typically expressed in megapascals (MPa) or pounds per square inch (psi). |

| Applications | Used in beam design, structural elements under bending stresses. | Used in cables, wires, and components under axial tension. |

| Failure Mode | Failure occurs due to bending-induced tensile and compressive stresses. | Failure occurs due to material separation from tensile stress. |

| Influencing Factors | Cross-section shape, surface defects, material heterogeneity. | Material ductility, grain structure, temperature effects. |

Introduction to Flexural and Tensile Strength

Flexural strength measures a material's ability to resist deformation under bending stress, making it crucial for structures subjected to bending forces. Tensile strength quantifies the maximum stress a material can withstand while being stretched or pulled before breaking, critical for components experiencing tension. Understanding these strengths helps engineers select appropriate materials for applications requiring resistance to bending or pulling forces.

Defining Flexural Strength

Flexural strength measures a material's ability to resist deformation under bending forces, highlighting its capacity to withstand stress in applications involving bending or flexure. It is defined as the maximum stress experienced within a material at the moment of failure in a bending test. This property is crucial for materials used in beams, bridges, and structural panels where bending loads are common, distinguishing it from tensile strength, which assesses resistance to tension or pulling forces.

Defining Tensile Strength

Tensile strength is the maximum stress a material can withstand while being stretched or pulled before breaking, measured in units such as megapascals (MPa). It indicates the ability of a material to resist forces that attempt to elongate it, critical in applications involving tension. Unlike flexural strength, which measures resistance to bending forces, tensile strength specifically assesses a material's resistance to linear pulling forces.

Key Differences: Flexural vs Tensile Strength

Flexural strength measures a material's ability to resist deformation under bending forces, whereas tensile strength indicates the maximum stress a material can withstand while being stretched or pulled before breaking. Flexural strength is critical in applications like beams and slabs where bending is predominant, while tensile strength is essential for components subjected to direct pulling forces. The primary difference lies in the type of stress applied: bending stress for flexural and uniaxial tensile stress for tensile strength.

Testing Methods for Flexural Strength

Flexural strength testing primarily involves three-point or four-point bending tests, where a specimen is subjected to a load until failure, measuring its resistance to bending stress. These methods use standardized sample dimensions and loading rates, providing precise data on material behavior under flexural load. Compared to tensile strength tests, which directly measure resistance to pulling forces, flexural strength tests reveal material performance in structural applications involving bending stresses.

Testing Methods for Tensile Strength

Tensile strength testing primarily involves methods such as the uniaxial tensile test, where a specimen is subjected to controlled tension until failure, providing critical data on its maximum load-bearing capacity. The use of universal testing machines (UTM) with extensometers or strain gauges ensures precise measurement of elongation and stress. Unlike flexural strength testing, which evaluates resistance to bending, tensile testing directly assesses material behavior under axial loads, essential for structural and mechanical performance analysis.

Importance in Material Selection

Flexural strength measures a material's ability to resist deformation under bending stress, crucial for applications involving beams or structural components subjected to bending loads. Tensile strength indicates a material's resistance to breaking under tension, essential for parts experiencing stretching or pulling forces. Understanding both properties ensures optimal material selection, balancing durability and performance in engineering designs.

Factors Affecting Flexural and Tensile Strength

Flexural strength depends on the material's ability to resist deformation under bending forces, influenced by factors such as fiber orientation, matrix composition, and specimen geometry. Tensile strength is affected by the material's molecular structure, strain rate, temperature, and presence of defects or voids within the specimen. Both strengths are altered by environmental conditions like humidity and temperature, which can degrade polymer matrices or cause microcracks in composites.

Applications: When to Consider Each Strength

Flexural strength is critical in applications involving bending stresses, such as beams, floor slabs, and roofing panels, where materials must resist deformation under load. Tensile strength is essential in components subjected to pulling forces, like cables, ropes, and connectors, where resistance to breaking under tension is required. Selecting between flexural and tensile strength depends on the primary load type and structural demands specific to the engineering or construction project.

Summary: Flexural Strength vs Tensile Strength

Flexural strength measures a material's ability to resist deformation under bending stress, while tensile strength quantifies resistance to tension or pulling forces. Materials with high tensile strength often exhibit lower flexural strength due to differences in stress distribution and failure modes. Understanding both properties is crucial for selecting appropriate materials in structural applications requiring resistance to bending and stretching forces.

Flexural strength Infographic

libterm.com

libterm.com