Air cooled heat exchangers use ambient air to dissipate heat from fluids, making them energy-efficient and environmentally friendly solutions in various industries. These devices eliminate the need for water, reducing operational costs and the risk of corrosion or fouling. Discover how an air cooled heat exchanger can optimize Your cooling processes by exploring the rest of this article.

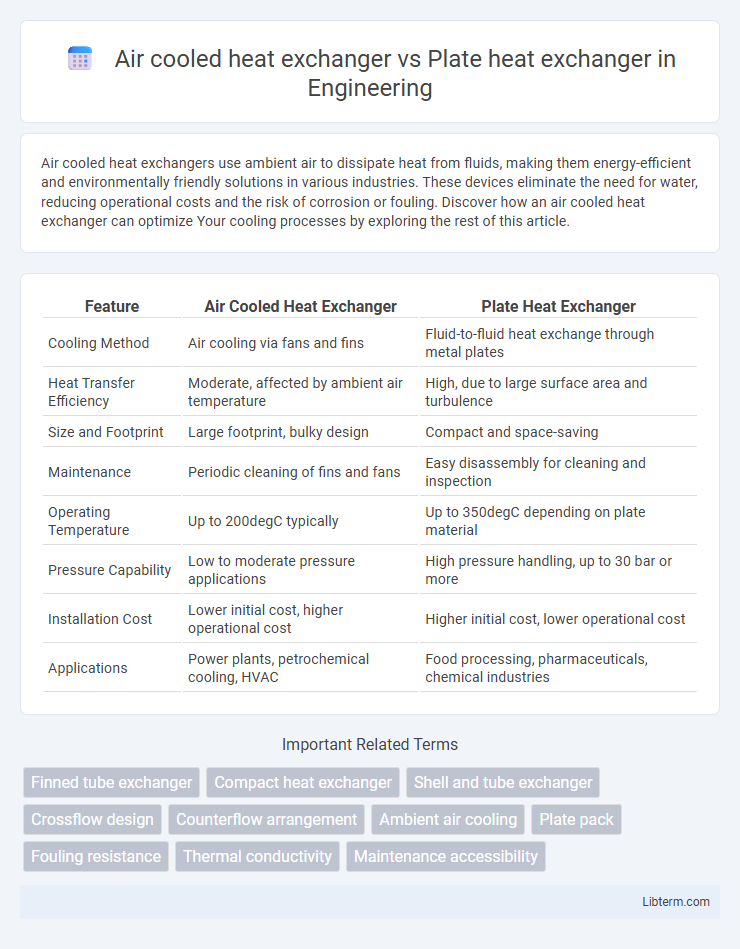

Table of Comparison

| Feature | Air Cooled Heat Exchanger | Plate Heat Exchanger |

|---|---|---|

| Cooling Method | Air cooling via fans and fins | Fluid-to-fluid heat exchange through metal plates |

| Heat Transfer Efficiency | Moderate, affected by ambient air temperature | High, due to large surface area and turbulence |

| Size and Footprint | Large footprint, bulky design | Compact and space-saving |

| Maintenance | Periodic cleaning of fins and fans | Easy disassembly for cleaning and inspection |

| Operating Temperature | Up to 200degC typically | Up to 350degC depending on plate material |

| Pressure Capability | Low to moderate pressure applications | High pressure handling, up to 30 bar or more |

| Installation Cost | Lower initial cost, higher operational cost | Higher initial cost, lower operational cost |

| Applications | Power plants, petrochemical cooling, HVAC | Food processing, pharmaceuticals, chemical industries |

Introduction to Heat Exchangers

Heat exchangers transfer thermal energy between fluids to regulate temperatures in industrial and HVAC systems. Air cooled heat exchangers utilize ambient air to dissipate heat without needing a cooling medium, making them ideal for remote or water-scarce environments. Plate heat exchangers maximize surface area with thin corrugated plates, achieving high heat transfer efficiency in compact units suitable for process heating and cooling applications.

Overview of Air Cooled Heat Exchangers

Air cooled heat exchangers use ambient air to dissipate heat from fluids, eliminating the need for water as a cooling medium, which makes them ideal for remote or water-scarce locations. They consist of finned tubes and axial or centrifugal fans that enhance heat transfer by increasing air velocity and surface area. Their design offers advantages in maintenance, energy efficiency, and environmental impact compared to plate heat exchangers, which rely on liquid media and plate surfaces for heat exchange.

Overview of Plate Heat Exchangers

Plate heat exchangers consist of multiple thin, corrugated metal plates that create a large surface area for efficient thermal transfer between fluids. They offer compact design, ease of maintenance, and superior heat transfer efficiency compared to air-cooled heat exchangers. The modular structure allows for flexible capacity adjustments and effective handling of high-pressure applications in industries like HVAC, food processing, and chemical manufacturing.

Core Working Principles

Air cooled heat exchangers transfer heat by using ambient air to absorb thermal energy from hot fluids through finned tubes, relying on forced or natural convection. Plate heat exchangers utilize a series of thin, corrugated metal plates to create multiple flow channels, allowing heat transfer between fluids with high surface area and turbulence, enhancing efficiency. The fundamental difference lies in air cooled exchangers using air as the cooling medium, while plate heat exchangers rely on direct fluid-to-fluid conduction through metal plates.

Efficiency and Performance Comparison

Air cooled heat exchangers typically exhibit lower thermal efficiency compared to plate heat exchangers due to their reliance on ambient air for cooling, which limits heat transfer rates and increases temperature approach differences. Plate heat exchangers offer superior performance with higher heat transfer coefficients and compact design, enabling efficient thermal exchange in smaller footprints and reduced fluid volume. Efficiency in plate heat exchangers remains consistently higher across varying flow rates and temperatures, making them ideal for applications requiring precise temperature control and energy savings.

Installation and Space Requirements

Air cooled heat exchangers require significant outdoor space and support structures due to their large finned surfaces and fan assemblies, making installation more complex in confined areas. Plate heat exchangers have a compact footprint and modular design, allowing for easier installation in limited spaces and straightforward integration into piping systems. Their plate arrangement enables flexible capacity adjustments, minimizing spatial demands compared to bulky air cooled units.

Maintenance and Longevity

Air cooled heat exchangers require regular cleaning of fins and fans to prevent dust buildup, ensuring efficient heat transfer and extending operational lifespan. Plate heat exchangers demand periodic gasket inspection and replacement to avoid leaks, with cleaning between plates necessary to maintain optimal performance and durability. Proper maintenance schedules for both types significantly enhance longevity, with plate heat exchangers generally offering easier access for cleaning and repairs, resulting in potentially lower maintenance costs over time.

Cost Analysis: Capital and Operating Expenses

Air cooled heat exchangers generally have higher initial capital costs due to the extensive fan systems and larger footprint required, but they benefit from lower operating expenses since they eliminate the need for cooling water or glycol loops. Plate heat exchangers typically incur lower upfront costs and occupy less space, yet their operating expenses can increase over time due to maintenance of gasket seals and the need for periodic cleaning to prevent fouling. Considering energy consumption, air cooled systems may have higher power usage for fans compared to the relatively low pumping costs of plate heat exchangers, influencing the total cost of ownership depending on the application scale and environmental conditions.

Industry Applications and Suitability

Air cooled heat exchangers are ideal for industries with limited water availability, such as power plants and petrochemical facilities, where they dissipate heat using ambient air, reducing water consumption and operational costs. Plate heat exchangers are widely used in food processing, pharmaceuticals, and HVAC systems due to their compact design, high heat transfer efficiency, and ease of maintenance, making them suitable for processes requiring precise temperature control and hygiene. The choice between these exchangers depends on factors like cooling medium availability, required heat transfer rate, and industry-specific hygiene standards.

Choosing the Right Heat Exchanger: Key Factors

Selecting the right heat exchanger depends on factors like thermal performance, space availability, maintenance requirements, and operating conditions. Air cooled heat exchangers are ideal for environments with limited water supply and moderate heat transfer demands, offering easier maintenance but lower efficiency compared to plate heat exchangers. Plate heat exchangers excel in compact installations requiring high heat transfer efficiency and ease of cleaning, making them suitable for applications with fluids prone to fouling or frequent temperature fluctuations.

Air cooled heat exchanger Infographic

libterm.com

libterm.com