Radial force refers to the force directed perpendicular to the axis of a rotating object, crucial in understanding the stresses experienced by components like bearings and shafts. This force impacts the durability and performance of mechanical systems by influencing wear and alignment. Explore the rest of the article to discover how radial force affects your machinery and how to optimize its management.

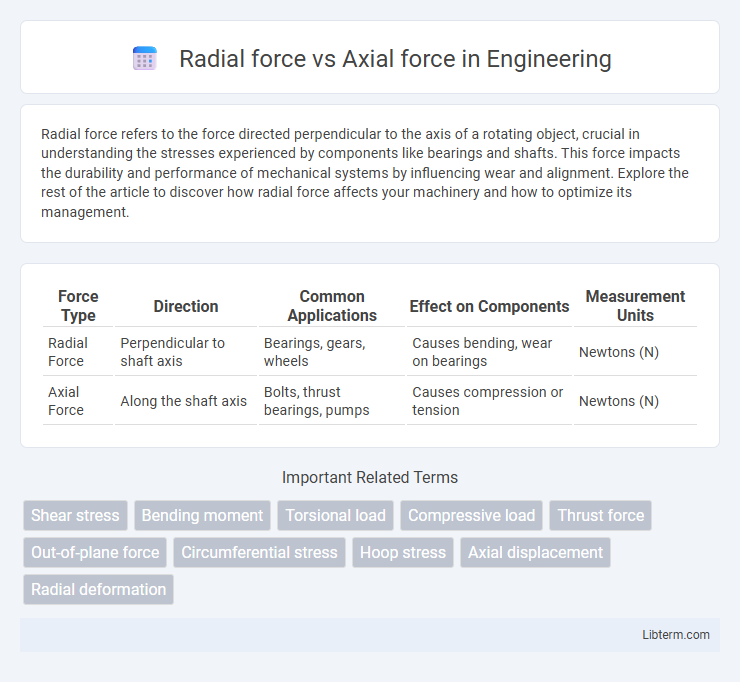

Table of Comparison

| Force Type | Direction | Common Applications | Effect on Components | Measurement Units |

|---|---|---|---|---|

| Radial Force | Perpendicular to shaft axis | Bearings, gears, wheels | Causes bending, wear on bearings | Newtons (N) |

| Axial Force | Along the shaft axis | Bolts, thrust bearings, pumps | Causes compression or tension | Newtons (N) |

Introduction to Radial and Axial Forces

Radial force acts perpendicular to the axis of rotation, pushing outward or inward from a central point, commonly observed in rotating machinery like bearings and wheels. Axial force, also known as thrust force, operates parallel to the axis of rotation, exerting pressure along the shaft's length. Understanding these forces is crucial for designing mechanical components to ensure durability and optimal performance under operational loads.

Definitions: What are Radial and Axial Forces?

Radial force acts perpendicular to the axis of a shaft, pushing outward or inward from the center, commonly experienced in rotating machinery such as bearings and wheels. Axial force, also known as thrust force, acts parallel to the shaft's axis, either pushing or pulling along the length of the shaft. Understanding the distinction between radial and axial forces is crucial for designing mechanical components that withstand operational stresses and maintain structural integrity.

Key Differences Between Radial and Axial Forces

Radial force acts perpendicular to the axis of rotation, pushing outward or inward along the radius, while axial force acts parallel to the axis, either compressing or stretching along the shaft length. Radial forces primarily cause bending stresses in rotating components, whereas axial forces induce tensile or compressive stresses along the axis. Understanding these distinctions is critical in designing bearings and shafts that can withstand operational loads effectively.

Measurement Techniques for Radial and Axial Forces

Measurement techniques for radial forces commonly involve load cells equipped with strain gauges positioned to detect forces perpendicular to the shaft, ensuring precise radial load assessment in rotating machinery. Axial force measurement often utilizes specialized force sensors mounted along the shaft axis, such as piezoelectric sensors or axial load cells, to accurately capture thrust loads during operation. Advanced methods incorporate telemetry systems and signal conditioning to improve the reliability and real-time monitoring of both radial and axial force measurements in dynamic environments.

Examples of Radial and Axial Forces in Engineering

Radial forces act perpendicular to the axis of rotation, such as the centrifugal force on the blades of a turbine or the load on the bearings of a rotating shaft. Axial forces, by contrast, act parallel to the axis and are observed in applications like the thrust force on a screw or the compressive load on a column in structural engineering. Understanding the distinctions between radial and axial forces is critical for designing mechanical components that withstand operational stresses while maintaining structural integrity.

Effects of Radial and Axial Forces on Machine Components

Radial forces act perpendicular to the shaft axis and primarily influence bearing wear and shaft deflection in rotating machinery. Axial forces, aligned with the shaft axis, affect thrust bearings and can cause axial displacement or end play in components such as seals and gears. Properly managing both forces is critical to preventing premature failure and ensuring operational stability of machine components.

Importance in Mechanical Design and Failure Analysis

Radial force and axial force critically influence mechanical design by determining load distribution and component stress levels, essential for optimizing bearing life and shaft durability. Accurate assessment of radial forces, acting perpendicular to the shaft axis, ensures proper alignment and minimizes wear, while axial forces, acting parallel, affect thrust load capacity and sealing integrity. Failure analysis often involves differentiating between these forces to identify fatigue points, misalignment, or lubrication issues, enabling targeted design improvements and maintenance strategies.

Radial vs Axial Load: Applications in Bearings

Radial loads act perpendicular to the shaft, exerting force outward from the center, while axial loads apply force parallel to the shaft's axis, either pushing or pulling along its length. Bearings like deep groove ball bearings are optimized for radial loads due to their ability to support high-speed rotation with minimal friction, whereas thrust ball bearings are specifically designed to handle axial loads in applications such as automotive transmissions and machine tool spindles. Understanding the distinction between radial and axial loads is crucial for selecting the correct bearing type to ensure durability and performance in mechanical systems.

Mitigating Radial and Axial Forces in Mechanical Systems

Mitigating radial and axial forces in mechanical systems requires the use of specialized bearings, such as deep groove ball bearings for combined load handling, and tapered roller bearings designed to support high axial loads alongside radial forces. Proper alignment and lubrication play critical roles in reducing the impact of these forces, preventing premature wear and extending component lifespan. Implementing force distribution techniques, such as shaft design optimization and load balancing, enhances system stability and operational efficiency under varying mechanical stresses.

Conclusion: Choosing the Right Solutions for Force Management

Selecting the appropriate solution for force management hinges on accurately distinguishing between radial force, which acts perpendicular to the shaft and affects bearing life, and axial force, which acts parallel and influences thrust capacity. Precision in force measurement and control ensures optimal performance in mechanical systems, preventing premature wear and failure. Engineering designs must prioritize the specific force type to enhance reliability, efficiency, and system longevity.

Radial force Infographic

libterm.com

libterm.com