A wound rotor is an essential component of a wound rotor induction motor, featuring three-phase windings placed on the rotor shaft, connected through slip rings and brushes to external resistors or controllers. This setup allows for adjustable starting torque and speed control, making it ideal for heavy-duty applications like cranes, hoists, and conveyors. Explore the rest of the article to understand how a wound rotor enhances motor performance and suitability for specific industrial tasks.

Table of Comparison

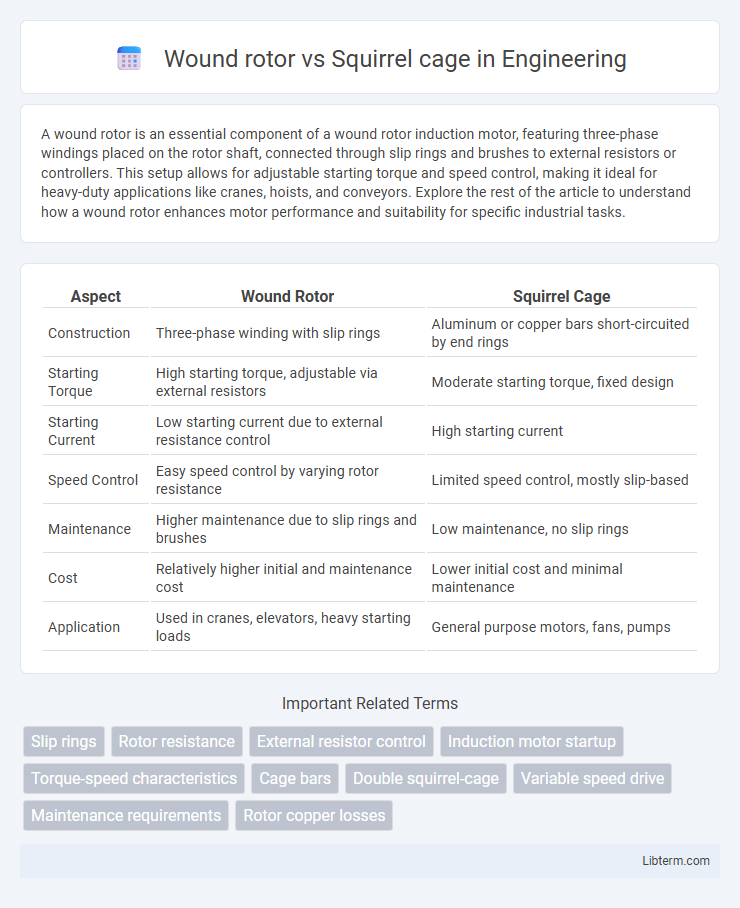

| Aspect | Wound Rotor | Squirrel Cage |

|---|---|---|

| Construction | Three-phase winding with slip rings | Aluminum or copper bars short-circuited by end rings |

| Starting Torque | High starting torque, adjustable via external resistors | Moderate starting torque, fixed design |

| Starting Current | Low starting current due to external resistance control | High starting current |

| Speed Control | Easy speed control by varying rotor resistance | Limited speed control, mostly slip-based |

| Maintenance | Higher maintenance due to slip rings and brushes | Low maintenance, no slip rings |

| Cost | Relatively higher initial and maintenance cost | Lower initial cost and minimal maintenance |

| Application | Used in cranes, elevators, heavy starting loads | General purpose motors, fans, pumps |

Overview of Wound Rotor and Squirrel Cage Motors

Wound rotor motors feature a rotor with windings connected to external resistors, allowing for adjustable starting torque and controlled speed during startup. Squirrel cage motors have a rotor made of conductive bars short-circuited by end rings, providing a simple, robust design with low maintenance and high efficiency. The key difference lies in the wound rotor's ability to vary resistance for better starting performance, while squirrel cage motors excel in reliability and cost-effectiveness.

Construction Differences Between Wound Rotor and Squirrel Cage

The construction difference between wound rotor and squirrel cage motors primarily lies in their rotor design; wound rotors feature three insulated windings connected to slip rings, allowing external resistance control, whereas squirrel cage rotors consist of aluminum or copper bars short-circuited by end rings, forming a simple, rugged structure. Wound rotor motors enable variable starting torque and reduced starting current due to external resistance integration, while squirrel cage motors offer low maintenance and robust operation with a fixed rotor design. These fundamental construction variations significantly impact their application suitability, control methods, and performance characteristics in industrial environments.

Operating Principles of Wound Rotor Motors

Wound rotor motors operate by incorporating a three-phase wound rotor connected through slip rings to external resistors, allowing control over rotor current and torque during start-up. This configuration enables adjustable starting torque and current by varying the external resistance, improving performance in heavy-load applications. Unlike squirrel cage motors, which have a fixed rotor design, wound rotor motors deliver enhanced speed control and reduced starting currents through this external resistance modulation.

Operating Principles of Squirrel Cage Motors

Squirrel cage motors operate using a rotor composed of conductive bars short-circuited by end rings, creating a robust and low-maintenance design that induces current through electromagnetic induction from the stator's rotating magnetic field. This operating principle ensures a simple construction, reliable starting torque, and minimal slip during operation compared to wound rotor motors, which use external resistors for speed control. The squirrel cage's inherent durability and efficiency make it ideal for constant-speed applications where maintenance accessibility is limited.

Performance Characteristics and Efficiency Comparison

Wound rotor motors provide superior starting torque and adjustable speed control through external resistance, making them ideal for heavy load applications, whereas squirrel cage motors offer simpler construction and higher reliability with lower maintenance requirements. In terms of efficiency, squirrel cage motors generally outperform wound rotor motors due to reduced rotor losses and the absence of slip rings and brushes. Performance characteristics favor wound rotor designs in variable torque applications, while squirrel cage motors excel in constant speed operations with higher energy efficiency.

Advantages of Wound Rotor Induction Motors

Wound rotor induction motors offer superior starting torque and adjustable speed control through external resistance insertion in the rotor circuit, making them ideal for heavy-duty applications like cranes and hoists. Their ability to limit inrush current reduces electrical stress and enhances motor longevity compared to squirrel cage motors. Furthermore, wound rotor motors provide better torque characteristics at low speeds, improving performance under varying load conditions.

Advantages of Squirrel Cage Induction Motors

Squirrel cage induction motors offer higher durability and low maintenance due to their robust construction without brushes or slip rings, reducing wear and tear. They exhibit better efficiency and reliability with simpler design, leading to consistent performance in industrial applications. These motors also provide cost-effective operation through lower initial investment and reduced servicing requirements compared to wound rotor motors.

Applications: Where Each Motor Type Excels

Wound rotor motors excel in applications requiring high starting torque and adjustable speed control, such as cranes, hoists, and conveyors in heavy industries. Squirrel cage motors are preferred in steady-speed, low-maintenance operations like pumps, fans, and compressors due to their robust design and simplicity. The choice between the two depends on load characteristics, with wound rotors suited for variable loads and squirrel cages ideal for constant-speed applications.

Cost Considerations and Maintenance Requirements

Wound rotor motors generally have higher initial costs due to their complex design with slip rings and brushes, whereas squirrel cage motors offer lower upfront expenses because of their simple, rugged construction. Maintenance requirements for wound rotor motors are more intensive, involving regular brush and slip ring inspection and replacement, while squirrel cage motors benefit from minimal maintenance with fewer moving parts exposed to wear. Cost considerations favor squirrel cage motors in applications where low maintenance and reliability are critical to minimizing total lifecycle expenses.

Choosing Between Wound Rotor and Squirrel Cage Motors

Choosing between wound rotor and squirrel cage motors depends heavily on application requirements such as starting torque, speed control, and maintenance needs. Wound rotor motors provide adjustable starting torque and speed control via external resistors, making them ideal for heavy load startups and variable speed applications. Squirrel cage motors offer simpler construction, lower maintenance, and higher efficiency, typically favored for constant speed operations and lower initial costs.

Wound rotor Infographic

libterm.com

libterm.com