Diaphragm pumps provide reliable and efficient fluid transfer by using a flexible diaphragm to create a vacuum that moves liquids without contaminating the flow. They are ideal for handling corrosive, viscous, or abrasive fluids in industries like chemical processing, water treatment, and food production. Discover how this versatile pumping solution can optimize your applications by reading the full article.

Table of Comparison

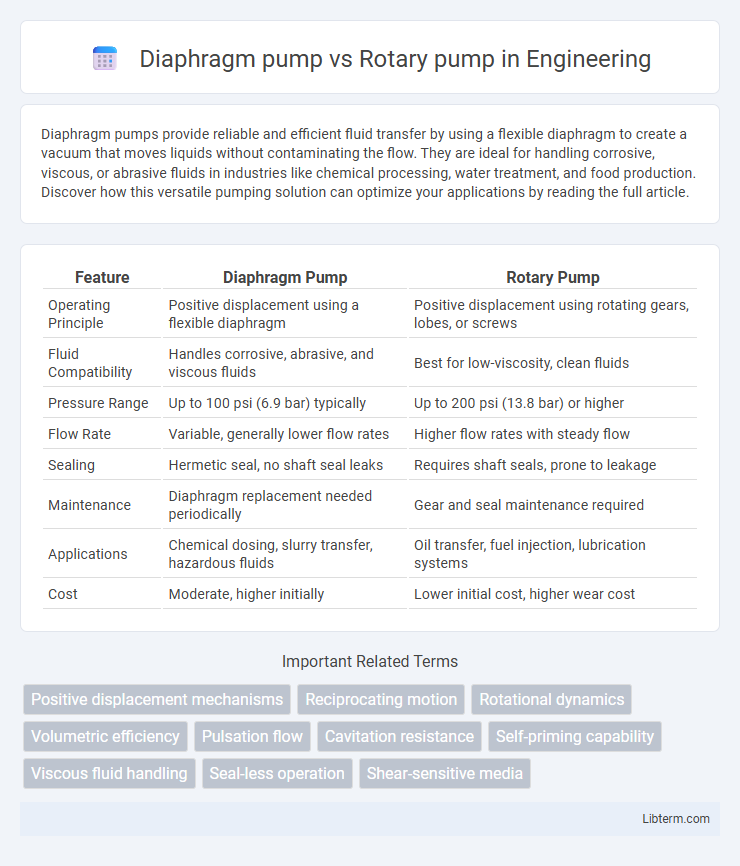

| Feature | Diaphragm Pump | Rotary Pump |

|---|---|---|

| Operating Principle | Positive displacement using a flexible diaphragm | Positive displacement using rotating gears, lobes, or screws |

| Fluid Compatibility | Handles corrosive, abrasive, and viscous fluids | Best for low-viscosity, clean fluids |

| Pressure Range | Up to 100 psi (6.9 bar) typically | Up to 200 psi (13.8 bar) or higher |

| Flow Rate | Variable, generally lower flow rates | Higher flow rates with steady flow |

| Sealing | Hermetic seal, no shaft seal leaks | Requires shaft seals, prone to leakage |

| Maintenance | Diaphragm replacement needed periodically | Gear and seal maintenance required |

| Applications | Chemical dosing, slurry transfer, hazardous fluids | Oil transfer, fuel injection, lubrication systems |

| Cost | Moderate, higher initially | Lower initial cost, higher wear cost |

Introduction to Diaphragm and Rotary Pumps

Diaphragm pumps use a flexible diaphragm driven by a mechanical or hydraulic actuator to create a variable volume chamber, enabling the displacement of fluids with excellent chemical resistance and dry-run capabilities. Rotary pumps employ rotating components such as gears, lobes, or vanes to transport fluids by trapping and moving fixed volumes, offering smooth flow and consistent pressure ideal for viscous liquids. Understanding these fundamental mechanisms highlights differences in efficiency, application suitability, and maintenance between diaphragm and rotary pumps.

Basic Operating Principles

Diaphragm pumps operate by using a flexible diaphragm that moves back and forth to create a variable volume chamber, generating suction and discharge pressure for fluid transfer. Rotary pumps utilize rotating gears, lobes, or vanes to trap fluid and move it through the pump, maintaining a continuous flow with minimal pulsation. The key distinction lies in the diaphragm pump's positive displacement mechanism driven by diaphragm flexing versus the rotary pump's mechanical rotation for fluid displacement.

Key Design Differences

Diaphragm pumps utilize a flexible diaphragm to create a variable volume chamber for fluid movement, offering excellent seal-less operation suitable for corrosive or abrasive fluids. Rotary pumps rely on the rotation of gears, lobes, or vanes to displace fluid, providing continuous flow with minimal pulsation and high efficiency in handling viscous liquids. Key design differences include diaphragm pumps' positive displacement and pulsatile flow versus rotary pumps' smooth, volumetric displacement without direct contact between fluid and moving parts.

Performance and Efficiency Comparison

Diaphragm pumps deliver precise, pulsation-free flow ideal for handling viscous and abrasive fluids, boasting high efficiency in metering and dosing applications. Rotary pumps provide consistent, smooth flow with superior volumetric efficiency, excelling in high-pressure tasks and transferring low-viscosity fluids efficiently. Performance varies with fluid type and system conditions, where diaphragm pumps offer leak-free operation and rotary pumps achieve better energy efficiency in continuous, high-volume processes.

Applications: Where Each Pump Excels

Diaphragm pumps excel in industries requiring precise, contamination-free fluid transfer such as pharmaceuticals, food processing, and chemical dosing where handling corrosive or abrasive liquids is critical. Rotary pumps are preferred in applications demanding consistent flow rates and high efficiency, including oil transfer, fuel pumping, and hydraulic systems in manufacturing or automotive sectors. Both pump types optimize performance based on fluid viscosity, pressure requirements, and the need for contamination control, making them ideal for specific industrial processes.

Maintenance and Durability

Diaphragm pumps require minimal maintenance due to their simple design and lack of mechanical seals, making them highly resistant to wear and corrosion, which enhances durability in abrasive or harsh fluid applications. Rotary pumps often demand more frequent maintenance, including seal and bearing replacements, due to their complex moving parts that are subject to wear and potential leaks. The durability of diaphragm pumps typically surpasses rotary pumps in handling aggressive chemicals or solids, while rotary pumps excel in consistent, high-pressure fluid transfer with routine upkeep.

Handling of Different Fluids

Diaphragm pumps excel in handling abrasive, viscous, and shear-sensitive fluids due to their gentle, pulsation-free pumping action and hermetic sealing, preventing fluid contamination. Rotary pumps, such as gear or lobe types, are better suited for low-viscosity, clean fluids but can struggle with solids or highly viscous materials, risking wear and reduced performance. Selecting the right pump depends on fluid properties like viscosity, abrasiveness, and the presence of particulates to ensure efficient and reliable operation.

Cost Analysis and Affordability

Diaphragm pumps generally have lower upfront costs and simpler maintenance requirements, making them more affordable for applications with smaller budgets or intermittent use. Rotary pumps often involve higher initial investment due to complex components but offer greater efficiency and durability in continuous operation, potentially reducing long-term operating expenses. Evaluating total cost of ownership, including energy consumption, spare parts, and downtime, is essential for selecting the most cost-effective pump type.

Environmental Impact and Safety

Diaphragm pumps exhibit excellent environmental safety due to their leak-free, hermetic sealing, preventing hazardous fluid spills and minimizing volatile organic compound (VOC) emissions. Rotary pumps, while efficient, tend to have higher risk of leaks and fluid contamination because of close clearances and mechanical seals, increasing environmental hazards. Diaphragm pumps operate with lower risk of ignition and explosion in volatile environments, offering superior safety in handling corrosive or hazardous chemicals compared to rotary pumps.

Choosing the Right Pump for Your Needs

Diaphragm pumps excel in handling abrasive, corrosive, or viscous fluids due to their seal-less design and ability to run dry without damage, making them ideal for chemical dosing or wastewater treatment. Rotary pumps provide steady, low-pulsation flow with high efficiency, suited for applications requiring precise flow control such as lubrication or fuel transfer. Selecting the right pump depends on factors like fluid type, flow rate, pressure requirements, and maintenance preferences to optimize performance and longevity.

Diaphragm pump Infographic

libterm.com

libterm.com