TIG welding delivers precise, high-quality welds by using a non-consumable tungsten electrode and an inert gas shield, making it ideal for thin metals and intricate projects. Its control over heat input minimizes distortion and ensures strong, clean joints suitable for aluminum, stainless steel, and other alloys. Discover how mastering TIG welding techniques can enhance Your fabrication skills in the rest of this article.

Table of Comparison

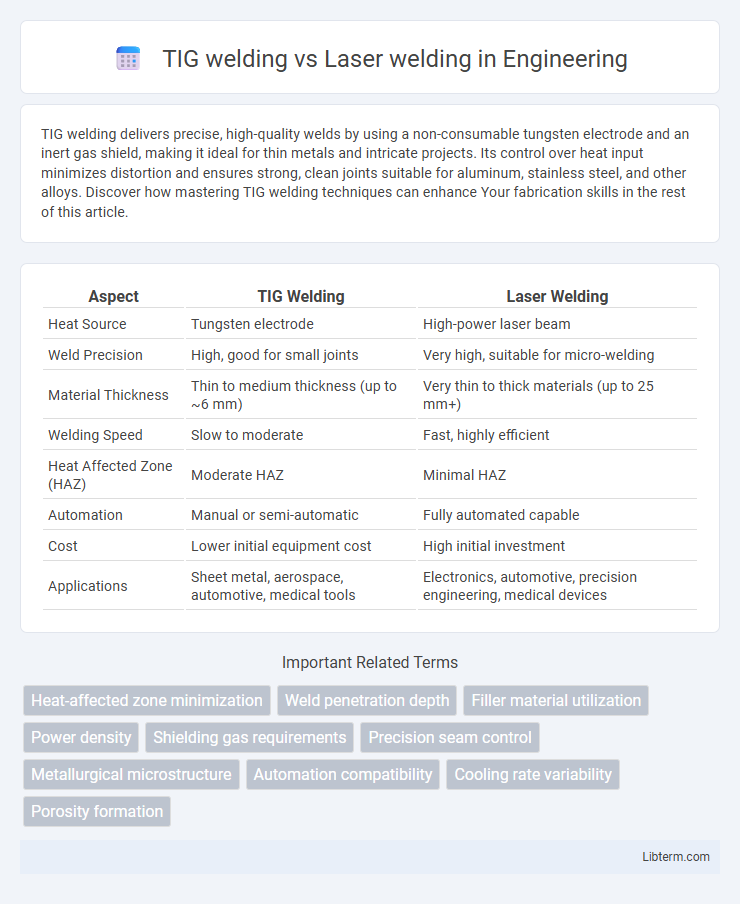

| Aspect | TIG Welding | Laser Welding |

|---|---|---|

| Heat Source | Tungsten electrode | High-power laser beam |

| Weld Precision | High, good for small joints | Very high, suitable for micro-welding |

| Material Thickness | Thin to medium thickness (up to ~6 mm) | Very thin to thick materials (up to 25 mm+) |

| Welding Speed | Slow to moderate | Fast, highly efficient |

| Heat Affected Zone (HAZ) | Moderate HAZ | Minimal HAZ |

| Automation | Manual or semi-automatic | Fully automated capable |

| Cost | Lower initial equipment cost | High initial investment |

| Applications | Sheet metal, aerospace, automotive, medical tools | Electronics, automotive, precision engineering, medical devices |

Introduction to TIG Welding and Laser Welding

TIG welding, or Tungsten Inert Gas welding, uses a non-consumable tungsten electrode to create precise, high-quality welds on metals such as stainless steel and aluminum, offering excellent control over weld penetration and minimal distortion. Laser welding employs a focused laser beam to produce deep, narrow welds with high speed and automation potential, making it ideal for applications requiring high precision and repeatability. Both methods serve distinct industrial needs, with TIG welding favored for intricate manual work and laser welding suited for high-volume production.

How TIG Welding Works

TIG welding operates by generating an arc between a non-consumable tungsten electrode and the workpiece, using an inert gas such as argon to shield the weld area from atmospheric contamination. This process allows for precise control over heat input and weld pool, making it ideal for thin materials and intricate joints. The controlled environment and focused heat source enable high-quality, clean welds with minimal spatter, suitable for metals like aluminum, stainless steel, and titanium.

How Laser Welding Works

Laser welding uses a high-powered laser beam to melt and fuse materials precisely at the joint, creating deep, narrow welds with minimal heat-affected zones. The laser's concentrated energy allows for high welding speeds and strong, clean joints, ideal for metals and alloys requiring tight tolerances. Unlike TIG welding, which relies on an electric arc, laser welding offers improved automation and reduced distortion in industrial applications.

Key Differences Between TIG and Laser Welding

TIG welding utilizes a tungsten electrode to produce a precise, high-quality weld with excellent control over heat input, ideal for thin metals and intricate joints. Laser welding employs a concentrated laser beam to achieve deep penetration and high welding speed, making it suitable for thick materials and automated production. Key differences include heat source type, control precision, weld penetration depth, and speed, with TIG offering superior finesse and laser welding excelling in efficiency and scalability.

Material Compatibility in TIG vs Laser Welding

TIG welding offers exceptional compatibility with a wide range of metals including stainless steel, aluminum, and copper alloys due to its precise heat control, making it ideal for thin and delicate materials. Laser welding excels in joining dissimilar materials such as steel to aluminum or titanium to nickel alloys, leveraging its concentrated energy for minimal thermal distortion and high precision. Material compatibility in TIG welding is governed by electrode selection and shielding gas, whereas laser welding relies on laser wavelength and power density to optimize joint quality across diverse substrates.

Precision and Weld Quality Comparison

TIG welding provides excellent control over heat input, resulting in high precision and clean welds ideal for thin materials and critical applications, but typically requires more operator skill and time. Laser welding offers superior precision with its focused energy beam, producing narrow, deep welds with minimal thermal distortion and high repeatability, making it suitable for automated, high-speed production environments. Weld quality in laser welding tends to be more consistent and less prone to defects like porosity and warping compared to TIG welding, especially in complex or high-volume tasks.

Speed and Efficiency: TIG vs Laser Welding

Laser welding offers significantly higher speed and efficiency compared to TIG welding, achieving precise welds within seconds due to its concentrated energy source. TIG welding, while providing superior control and weld quality, operates at a slower pace and requires more manual skill, making it less efficient for high-volume production. Industrial applications prioritize laser welding for rapid throughput and minimal heat distortion, enhancing overall manufacturing productivity.

Cost Analysis: TIG Welding vs Laser Welding

TIG welding generally incurs lower initial equipment costs but higher labor expenses due to its slower welding speed and manual operation, making it suitable for small-scale or precision projects. Laser welding involves significant upfront investment in high-tech machinery, yet its faster processing time and automation reduce long-term labor costs and increase production efficiency. Evaluating total ownership costs reveals that laser welding is more cost-effective for large-volume manufacturing, while TIG welding remains economical for low-volume, intricate work.

Common Applications for TIG and Laser Welding

TIG welding is commonly used in aerospace, automotive, and art fabrication due to its precision and control with thin materials and non-ferrous metals like aluminum and stainless steel. Laser welding excels in high-speed, automated manufacturing processes for electronics, medical devices, and micro-welding applications, offering deep penetration and minimal thermal distortion. Both methods serve critical roles in industries demanding strong, clean welds on diverse materials and complex geometries.

Choosing the Right Welding Method for Your Project

TIG welding offers precise control and deep penetration, ideal for thin metals and intricate joints, while laser welding provides high speed and narrow heat-affected zones, perfect for automation and thicker materials. Evaluating factors such as material type, joint design, production volume, and budget is crucial in selecting the optimal welding technique. Laser welding excels in high-volume manufacturing with minimal distortion, whereas TIG welding suits projects requiring superior weld quality and flexibility.

TIG welding Infographic

libterm.com

libterm.com