Compression reduces file sizes by encoding data more efficiently, saving storage space and speeding up file transfers. It applies to various types of files including images, videos, and documents, using methods like lossless or lossy compression depending on your needs. Explore the full article to learn how compression can optimize your digital workflows and improve performance.

Table of Comparison

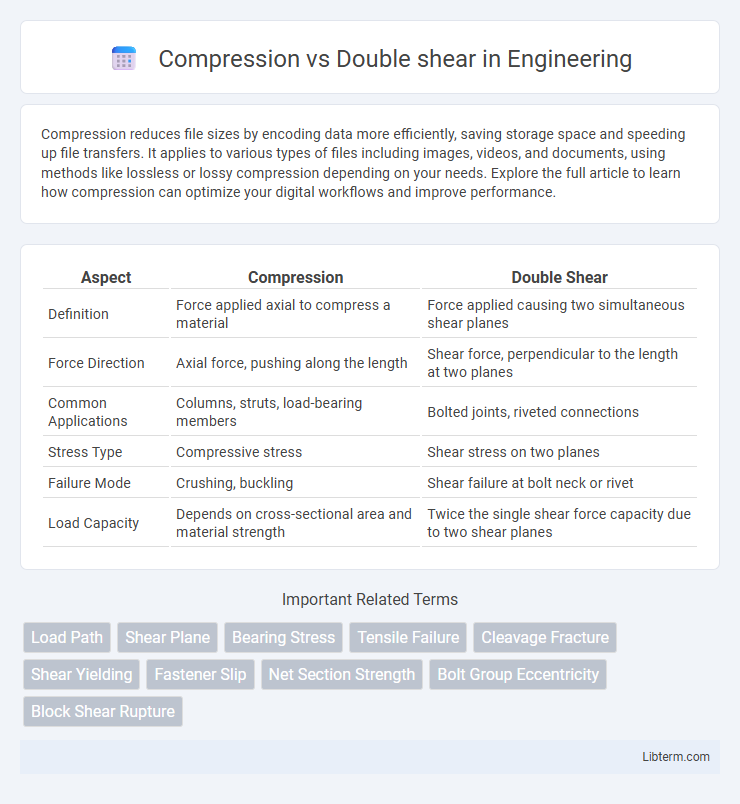

| Aspect | Compression | Double Shear |

|---|---|---|

| Definition | Force applied axial to compress a material | Force applied causing two simultaneous shear planes |

| Force Direction | Axial force, pushing along the length | Shear force, perpendicular to the length at two planes |

| Common Applications | Columns, struts, load-bearing members | Bolted joints, riveted connections |

| Stress Type | Compressive stress | Shear stress on two planes |

| Failure Mode | Crushing, buckling | Shear failure at bolt neck or rivet |

| Load Capacity | Depends on cross-sectional area and material strength | Twice the single shear force capacity due to two shear planes |

Understanding Compression and Double Shear

Compression involves forces that push materials together, causing them to shorten or become compacted under load, commonly analyzed in columns and structural supports. Double shear occurs when a material experiences two simultaneous shear planes, effectively doubling the shear area and increasing the load capacity compared to single shear scenarios. Understanding these concepts is crucial for designing safe structures, as compression affects axial strength while double shear enhances joint and fastener performance under lateral loads.

Fundamental Concepts of Compression

Compression involves forces that push materials together, causing a decrease in length and an increase in cross-sectional area, essential for analyzing load-bearing capacity in structural elements. Double shear occurs when a material experiences two shear planes, doubling the shear resistance compared to single shear, critical in joint and fastener design. Understanding compression fundamentals like stress distribution, strain behavior, and buckling resistance is vital for optimizing material performance under compressive loads.

Basic Principles of Double Shear

Double shear involves two distinct shear planes, effectively doubling the load-bearing capacity compared to single shear. Compression in double shear primarily results from force distributed across two interfaces, reducing stress concentration on each plane. This arrangement enhances structural stability by ensuring load transfer through multiple sections, minimizing the risk of material failure.

Key Differences Between Compression and Double Shear

Compression involves a material experiencing forces that push inward, leading to a reduction in size or volume, while double shear occurs when a material is subjected to two simultaneous shear forces acting in opposite directions, causing it to potentially fail along two shear planes. Key differences include the type of stress: compression deals with normal stress perpendicular to the surface, whereas double shear involves shear stress parallel to the surface. In design and analysis, compression capacity is determined by the material's yield strength under compressive load, while double shear strength relies on the shear area and shear strength of the material across the shear planes.

Mechanical Behavior Under Compression

Compression involves axial forces that reduce the length of a material by pushing it inward, resulting in deformation characterized by increased stress and potential buckling under excessive load. Double shear occurs when a material is subjected to two shear forces acting on two distinct planes, commonly seen in fasteners or joints where the load is distributed across two cross-sectional areas, providing greater resistance to shear failure. Mechanical behavior under compression differs fundamentally from double shear, as compression primarily deals with direct axial stress and material densification, while double shear addresses the material's ability to resist sliding failure along shear planes.

Load Distribution in Double Shear

Double shear joints provide superior load distribution by splitting the applied force across two shear planes, effectively doubling the area resisting the load compared to single shear. This enhanced load sharing reduces stress concentration on individual fasteners, leading to increased joint strength and durability under compressive forces. The redundancy in load paths minimizes deformation and potential failure, making double shear ideal for high-load structural applications.

Applications of Compression in Engineering

Compression is widely utilized in structural engineering to bear heavy loads in columns, arches, and beams, ensuring stability and strength in buildings and bridges. The material properties under compression influence design decisions, especially in concrete and steel components subjected to axial forces. Compression testing also aids in evaluating material behavior, optimizing construction safety, and preventing structural failure under high-pressure conditions.

Uses of Double Shear in Structural Design

Double shear connections are widely utilized in structural design to enhance load distribution and increase joint strength by allowing forces to be transferred through two shear planes, reducing stress concentration. This method is particularly effective in steel frameworks, timber trusses, and bolted or riveted connections where higher resistance to shear failure is required. Double shear is preferred over single shear in critical load-bearing components, improving the durability and safety of bridges, buildings, and heavy machinery assemblies.

Advantages and Limitations of Each Method

Compression joints excel in simplicity, cost-effectiveness, and ease of installation, providing superior performance in bearing loads and axial forces. Double shear joints offer enhanced strength and load distribution by resisting forces from two planes, reducing joint failure under tension and shear stress. However, compression joints may struggle under complex multi-directional loads, while double shear connections can be more complex to design and manufacture, increasing overall construction time and cost.

Choosing Between Compression and Double Shear

Choosing between compression and double shear depends on the specific load conditions and structural requirements. Compression is ideal for components subjected to axial loads, maximizing material strength under direct pressure, while double shear provides enhanced resistance in connections by distributing shear forces across two planes. Understanding the mechanical behavior and failure modes in materials like steel or aluminum is essential to optimize design safety and efficiency.

Compression Infographic

libterm.com

libterm.com