The Stirling cycle is a thermodynamic process that operates through cyclic compression and expansion of air or other gases at different temperature levels, converting heat energy into mechanical work with high efficiency. Its closed system design minimizes energy losses, making it ideal for engines and refrigeration systems where fuel economy and reduced emissions are critical. Discover how your applications can benefit from the Stirling cycle's principles and explore its potential uses throughout the rest of this article.

Table of Comparison

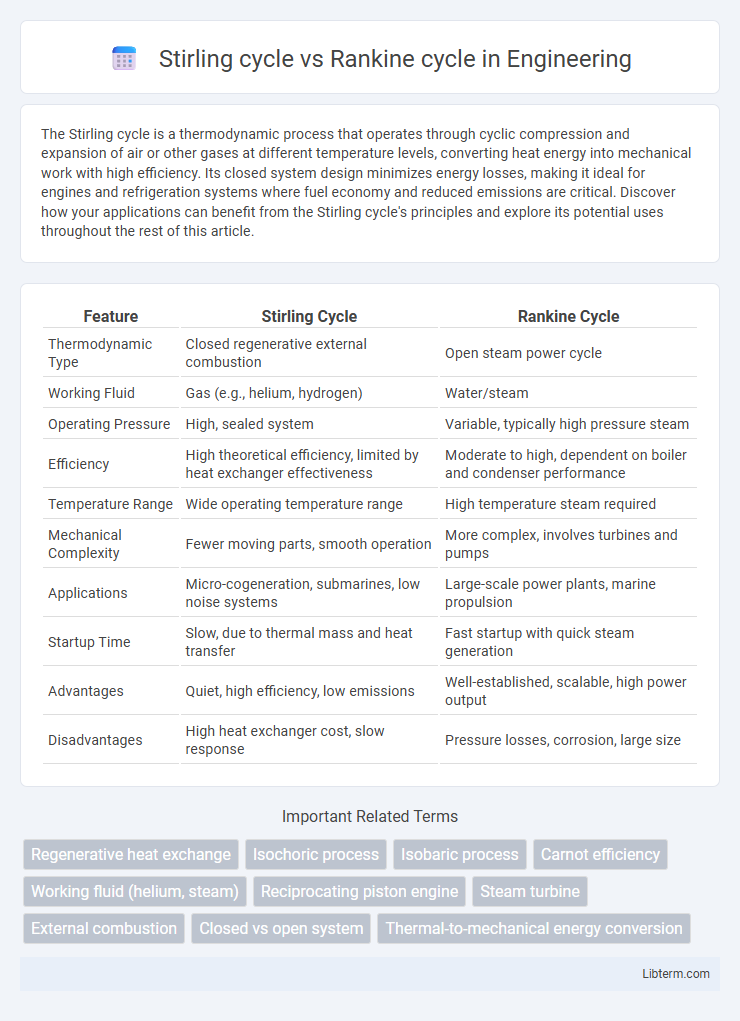

| Feature | Stirling Cycle | Rankine Cycle |

|---|---|---|

| Thermodynamic Type | Closed regenerative external combustion | Open steam power cycle |

| Working Fluid | Gas (e.g., helium, hydrogen) | Water/steam |

| Operating Pressure | High, sealed system | Variable, typically high pressure steam |

| Efficiency | High theoretical efficiency, limited by heat exchanger effectiveness | Moderate to high, dependent on boiler and condenser performance |

| Temperature Range | Wide operating temperature range | High temperature steam required |

| Mechanical Complexity | Fewer moving parts, smooth operation | More complex, involves turbines and pumps |

| Applications | Micro-cogeneration, submarines, low noise systems | Large-scale power plants, marine propulsion |

| Startup Time | Slow, due to thermal mass and heat transfer | Fast startup with quick steam generation |

| Advantages | Quiet, high efficiency, low emissions | Well-established, scalable, high power output |

| Disadvantages | High heat exchanger cost, slow response | Pressure losses, corrosion, large size |

Introduction to Thermodynamic Cycles

The Stirling cycle operates on a closed regenerative thermodynamic process involving isothermal expansion and compression, making it highly efficient for converting heat into work with minimal energy loss. The Rankine cycle, fundamental to steam power plants, uses phase change of a working fluid between liquid and vapor states to convert thermal energy into mechanical work, emphasizing practical heat exchange and condensation processes. Understanding these cycles highlights key principles in thermodynamics, such as energy conservation, heat transfer, and the efficiency limits of heat engines.

Overview of the Stirling Cycle

The Stirling cycle is a closed-cycle regenerative heat engine operating through cyclic compression and expansion of working fluid, typically gas, at different temperature levels. Unlike the Rankine cycle, which relies on phase change of the working fluid between liquid and vapor, the Stirling cycle uses isothermal expansion and compression processes coupled with external heat exchangers. Its high theoretical efficiency and capability to use various heat sources make it ideal for applications requiring quiet operation and renewable energy utilization.

Overview of the Rankine Cycle

The Rankine cycle is a thermodynamic process widely used in power generation to convert heat into mechanical work through phase changes of a working fluid, typically water. It consists of four main components: a boiler, turbine, condenser, and pump, where water is heated to produce steam that drives the turbine before being condensed and recycled. Compared to the Stirling cycle, the Rankine cycle is more commonly implemented in industrial-scale applications due to its efficiency with water-steam properties and established infrastructure.

Working Principles: Stirling vs Rankine

The Stirling cycle operates on a closed regenerative thermodynamic process using a fixed amount of gas, which is cyclically compressed and expanded at different temperature levels to convert heat into mechanical work. In contrast, the Rankine cycle uses phase changes of a working fluid, typically water, where the fluid is heated to produce steam, which expands in a turbine to generate power before condensation back to liquid form. The Stirling cycle's efficiency hinges on external heat sources and regeneration, while the Rankine cycle relies on internal phase transitions and heat exchange between boiler, turbine, condenser, and pump.

Key Components Comparison

The Stirling cycle utilizes a regenerator, cylinder, piston, and external heat source and sink to convert thermal energy into mechanical work, emphasizing closed-cycle operation with continuous external heating and cooling. In contrast, the Rankine cycle primarily comprises a boiler, turbine, condenser, and pump, using phase change of the working fluid (usually water/steam) to drive mechanical power in an open-cycle system. Key component differences include the Stirling cycle's reliance on gas as the working fluid and regenerative heat exchange, whereas the Rankine cycle depends on steam generation and condensation processes.

Efficiency and Performance Metrics

The Stirling cycle exhibits higher theoretical efficiency than the Rankine cycle due to its external combustion process and near-isothermal expansion and compression stages, enabling better utilization of heat energy. Performance metrics indicate that Stirling engines achieve efficiencies up to 40%, surpassing typical Rankine cycle efficiencies ranging from 30% to 35%, especially at smaller scales or low-temperature heat sources. However, the Rankine cycle remains dominant in large-scale power generation due to its robustness and suitability for high-pressure steam environments, despite lower thermodynamic efficiency compared to Stirling systems.

Applications in Modern Industry

The Stirling cycle excels in applications requiring quiet, efficient, and low-emission power generation such as solar power plants and submarine engines due to its external combustion process. The Rankine cycle remains dominant in large-scale electricity generation, especially in coal, nuclear, and geothermal power plants, because of its ability to efficiently convert heat from steam turbines into mechanical energy. Industries favor the Rankine cycle for robust, high-capacity operations, while the Stirling cycle is preferred in niche markets demanding compact, low-noise, and environmentally friendly energy solutions.

Environmental Impact and Sustainability

The Stirling cycle offers higher thermal efficiency and lower emissions due to external combustion and the ability to use renewable heat sources, enhancing sustainability. In contrast, the Rankine cycle, commonly used in steam power plants, often relies on fossil fuels, resulting in higher greenhouse gas emissions and greater environmental impact. Utilizing the Stirling cycle can significantly reduce carbon footprints in power generation by integrating biomass, solar, or waste heat, supporting long-term environmental goals.

Advantages and Limitations

The Stirling cycle offers high thermal efficiency and the ability to use various heat sources, including renewable energy, due to its closed regenerative system, which reduces fuel consumption and emissions. Its limitations include complex engine design, higher initial cost, and lower power density compared to the Rankine cycle, making it less suitable for large-scale power generation. The Rankine cycle is widely used for its simplicity, reliability, and capability to handle high power output in steam turbines, but it suffers from lower efficiency and environmental concerns tied to fossil fuel combustion and water consumption.

Future Prospects and Innovations

The Stirling cycle exhibits promising future prospects due to its high thermal efficiency and ability to utilize renewable heat sources like solar and biomass, making it ideal for sustainable energy solutions. Innovations in advanced materials and regenerative heat exchangers are enhancing the Stirling engine's durability and performance, enabling wider applications in micro-cogeneration and waste heat recovery systems. Conversely, the Rankine cycle continues to dominate large-scale power generation with ongoing advancements in supercritical and ultra-supercritical steam turbines, improving efficiency and reducing emissions in fossil fuel and nuclear plants.

Stirling cycle Infographic

libterm.com

libterm.com