Young's modulus measures a material's stiffness by quantifying the relationship between stress and strain in the elastic deformation region. It is a fundamental mechanical property essential for predicting how materials will behave under various forces. Explore the rest of the article to understand how Young's modulus impacts material selection and engineering design.

Table of Comparison

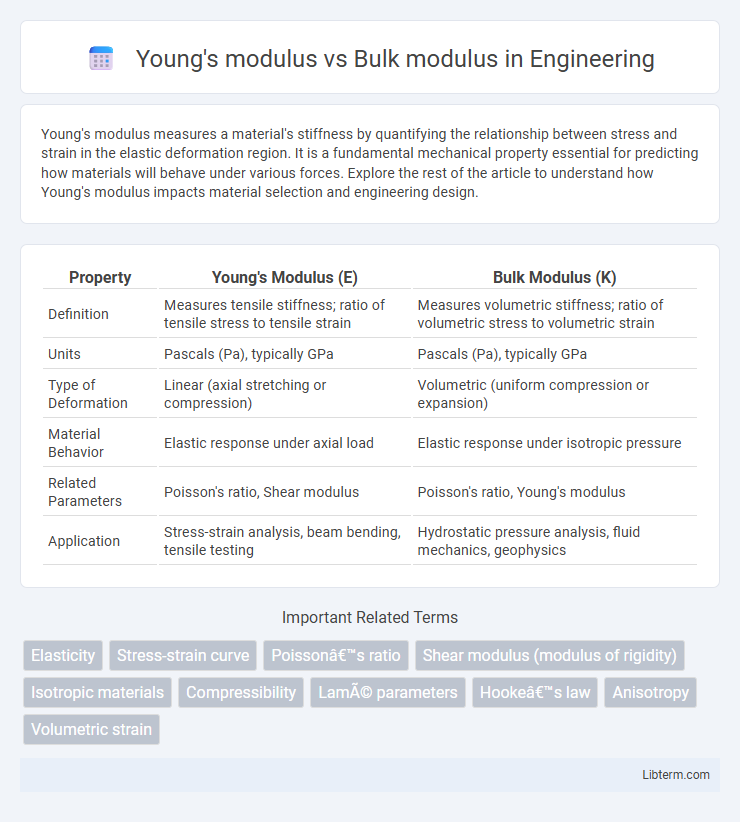

| Property | Young's Modulus (E) | Bulk Modulus (K) |

|---|---|---|

| Definition | Measures tensile stiffness; ratio of tensile stress to tensile strain | Measures volumetric stiffness; ratio of volumetric stress to volumetric strain |

| Units | Pascals (Pa), typically GPa | Pascals (Pa), typically GPa |

| Type of Deformation | Linear (axial stretching or compression) | Volumetric (uniform compression or expansion) |

| Material Behavior | Elastic response under axial load | Elastic response under isotropic pressure |

| Related Parameters | Poisson's ratio, Shear modulus | Poisson's ratio, Young's modulus |

| Application | Stress-strain analysis, beam bending, tensile testing | Hydrostatic pressure analysis, fluid mechanics, geophysics |

Introduction to Elastic Moduli

Young's modulus quantifies a material's stiffness by measuring its resistance to uniaxial tensile or compressive deformation, expressed as the ratio of stress to strain in the linear elasticity range. Bulk modulus defines a material's resistance to uniform volumetric compression, representing how incompressible a substance is under applied pressure. Both moduli are fundamental elastic constants crucial for characterizing mechanical behavior in solids, with Young's modulus emphasizing shape change and bulk modulus focusing on volume change.

Defining Young’s Modulus

Young's Modulus, also known as the modulus of elasticity, measures a material's ability to resist linear deformation under tensile stress, quantifying stiffness in one dimension. It is defined as the ratio of tensile stress to tensile strain within the elastic limit of the material. Unlike Bulk Modulus, which measures volumetric elasticity under uniform pressure, Young's Modulus specifically characterizes uniaxial elasticity and provides critical insights into the material's mechanical behavior under stretching or compressive forces.

Understanding Bulk Modulus

Bulk modulus measures a material's resistance to uniform compression and quantifies how incompressible a substance is under pressure. Unlike Young's modulus, which describes tensile stiffness and deformation in one direction, bulk modulus relates to volumetric changes under applied stress. High bulk modulus values indicate materials that maintain volume under stress, critical for applications involving fluid pressure or structural integrity in all directions.

Fundamental Differences Between Young’s and Bulk Modulus

Young's modulus measures a material's stiffness under uniaxial tensile or compressive stress, reflecting linear elasticity along one axis, while bulk modulus quantifies a material's resistance to uniform volumetric compression, representing volumetric elasticity. The fundamental difference lies in their stress-strain relationship: Young's modulus relates to axial strain and stress, whereas bulk modulus relates to volumetric strain and hydrostatic pressure. These distinctions make Young's modulus critical for applications involving bending or stretching, and bulk modulus essential for understanding material behavior under pressure changes.

Mathematical Expressions and Units

Young's modulus (E) quantifies the tensile elasticity of a material and is mathematically expressed as E = s/e, where s is stress (force per unit area, N/m2 or Pascals) and e is strain (dimensionless). Bulk modulus (K) measures a material's resistance to uniform compression and is defined as K = -V (dP/dV), with pressure P in Pascals and volume V in cubic meters. Both moduli share the unit Pascal (Pa), emphasizing their roles in characterizing mechanical stiffness under different loading conditions.

Physical Interpretation and Applications

Young's modulus measures a material's resistance to uniaxial tensile or compressive stress, reflecting its stiffness during stretching or compression along a single axis. Bulk modulus quantifies a material's response to uniform pressure applied isotropically, indicating its incompressibility and volumetric elasticity. Young's modulus is critical in structural engineering for bending and stretching analyses, while bulk modulus is essential in fluid mechanics, geophysics, and understanding material behavior under high-pressure environments.

Importance in Material Science

Young's modulus quantifies a material's tensile stiffness and resistance to elastic deformation under uniaxial stress, essential for designing structures that must withstand stretching or bending. Bulk modulus measures a material's resistance to uniform compression, critical in applications involving pressure changes and volumetric stability. Understanding both moduli is vital in materials science for selecting appropriate materials and predicting mechanical behavior under various loading conditions.

Factors Affecting Young’s and Bulk Modulus

Young's modulus and bulk modulus both measure material stiffness but respond differently to factors such as temperature, pressure, and material structure. Young's modulus primarily depends on atomic bonding strength and crystal structure, which dictate resistance to uniaxial deformation, while bulk modulus reflects resistance to uniform compression, influenced by volume changes and material density. Variations in temperature typically reduce both moduli by weakening interatomic forces, but anisotropy and microstructural defects impact Young's modulus more due to directional dependence.

Practical Examples and Comparisons

Young's modulus measures a material's stiffness during tensile or compressive stress, commonly evaluated in steel beams used in construction for their ability to resist bending. Bulk modulus quantifies a material's resistance to uniform compression, relevant in applications like hydraulic systems where fluids undergo pressure changes. Comparing both, rubber has a low Young's modulus indicating flexibility, but a relatively high bulk modulus, meaning it resists volume change under pressure, whereas metals such as aluminum exhibit high Young's and bulk moduli, reflecting strong resistance to shape and volume deformation.

Summary: Choosing the Right Modulus for Analysis

Young's modulus measures a material's stiffness under uniaxial tension or compression, while bulk modulus quantifies resistance to uniform volumetric compression. Selecting the right modulus depends on the nature of the applied stress: use Young's modulus for linear elastic deformation and bulk modulus for volumetric or hydrostatic pressure analysis. Accurate material characterization requires understanding these distinctions to ensure precise mechanical behavior predictions.

Young's modulus Infographic

libterm.com

libterm.com