Worm gears provide a compact and efficient means of transmitting torque between non-parallel, non-intersecting shafts, often achieving high gear reduction in a small space. Their unique design allows for smooth, quiet operation with self-locking capabilities, making them ideal for applications requiring precise control. Explore the rest of the article to discover how worm gears can optimize your mechanical systems.

Table of Comparison

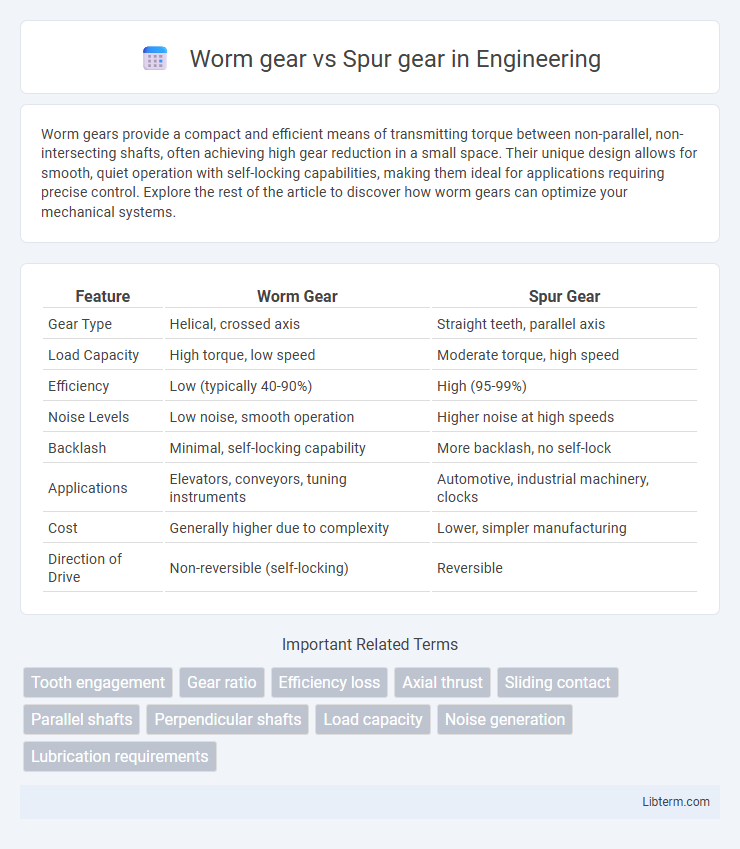

| Feature | Worm Gear | Spur Gear |

|---|---|---|

| Gear Type | Helical, crossed axis | Straight teeth, parallel axis |

| Load Capacity | High torque, low speed | Moderate torque, high speed |

| Efficiency | Low (typically 40-90%) | High (95-99%) |

| Noise Levels | Low noise, smooth operation | Higher noise at high speeds |

| Backlash | Minimal, self-locking capability | More backlash, no self-lock |

| Applications | Elevators, conveyors, tuning instruments | Automotive, industrial machinery, clocks |

| Cost | Generally higher due to complexity | Lower, simpler manufacturing |

| Direction of Drive | Non-reversible (self-locking) | Reversible |

Introduction to Worm Gears and Spur Gears

Worm gears consist of a worm (a screw-like component) meshing with a worm wheel, enabling high reduction ratios in compact spaces and providing smooth, quiet operation ideal for heavy load applications. Spur gears feature straight teeth mounted on parallel shafts, offering efficient power transmission with minimal friction and are commonly used for moderate speed and load scenarios. Both gear types serve distinct mechanical purposes, with worm gears excelling in torque multiplication and spur gears in straightforward, high-speed gear reduction.

Design and Construction Differences

Worm gears feature a screw-like worm meshing with a helical gear, allowing high reduction ratios in compact spaces, while spur gears have straight teeth parallel to the axis, providing efficient power transmission with simpler design. The worm gear's design enables smooth, quiet operation and self-locking capability due to its unique tooth engagement, whereas spur gears are easier to manufacture and maintain but generate more noise under load. Construction materials for worm gears often include bronze worms for improved wear resistance against steel spur gears, which typically use hardened steel teeth for durability.

Operating Principles

Worm gears operate through the interaction of a screw-like worm and a toothed wheel, enabling high torque reduction and smooth transmission by sliding contact. Spur gears rely on the direct meshing of parallel teeth, allowing efficient power transfer with minimal sliding and higher speed capabilities. These fundamental differences in operating principles determine their application in mechanical systems based on torque requirements and noise considerations.

Efficiency Comparison

Worm gears exhibit lower efficiency, typically ranging from 40% to 90%, due to increased sliding friction between the worm and the gear teeth. Spur gears achieve higher efficiency levels, often exceeding 95%, as their design promotes rolling contact, reducing energy loss. Efficiency differences significantly impact applications where energy conservation and heat generation are critical factors.

Load Capacity and Torque Transmission

Worm gears typically offer higher torque transmission due to their unique meshing design, which allows for greater load capacity in compact spaces compared to spur gears. Spur gears provide efficient power transfer with minimal losses but have lower load capacity and torque handling capabilities, especially at high speeds. The worm gear's ability to achieve high gear reduction ratios results in superior torque multiplication, making it ideal for heavy-load applications where space constraints exist.

Speed Reduction Capabilities

Worm gears provide significantly higher speed reduction ratios, often ranging from 20:1 up to 300:1, making them ideal for applications requiring substantial torque and precise speed control. Spur gears typically offer lower speed reduction ratios, generally between 2:1 and 10:1, suited for moderate speed and torque requirements. The unique meshing and sliding action of worm gears result in smoother, quieter operation but lower efficiency compared to the direct engagement of spur gears.

Noise and Vibration Levels

Worm gears operate with sliding contact between the worm and the gear, resulting in smoother motion and significantly reduced noise and vibration levels compared to spur gears, which rely on rolling contact and typically produce higher noise due to impact between teeth. The continuous engagement in worm gears absorbs shock loads more effectively, making them ideal for applications demanding quiet operation. Spur gears, while efficient, generate more vibration and noise at high speeds because of abrupt tooth engagement.

Maintenance and Durability

Worm gears require regular lubrication and inspection due to their sliding contact, which can cause higher wear and heat generation compared to spur gears that have rolling contact. Spur gears generally offer longer durability with less frequent maintenance, benefiting from their simpler tooth design and lower friction. Proper maintenance of worm gears involves monitoring oil quality and temperature to prevent premature failure, whereas spur gears benefit from routine cleaning and occasional lubrication.

Common Industrial Applications

Worm gears are commonly used in conveyors, elevators, and heavy-duty machinery where high torque and speed reduction are essential, providing smooth and quiet operation with self-locking capabilities. Spur gears find extensive applications in automotive transmissions, gearboxes, and machinery requiring high efficiency and simple design for transmitting motion between parallel shafts. Both gear types serve critical roles in industrial automation, with worm gears excelling in load-holding applications and spur gears in high-speed power transmission.

Choosing the Right Gear for Your Needs

Selecting the right gear depends on application requirements such as torque, speed, and space constraints. Worm gears provide high torque and compact design ideal for heavy-duty, low-speed applications, while spur gears offer efficient power transmission at higher speeds with simpler construction. Evaluating load capacity, noise levels, and maintenance needs ensures optimal performance and longevity in your machinery.

Worm gear Infographic

libterm.com

libterm.com