Structural weight significantly impacts the performance and efficiency of constructions and vehicles by influencing strength, stability, and fuel consumption. Reducing structural weight through advanced materials and innovative design enhances durability while minimizing costs. Explore the article to discover key strategies for optimizing structural weight in your projects.

Table of Comparison

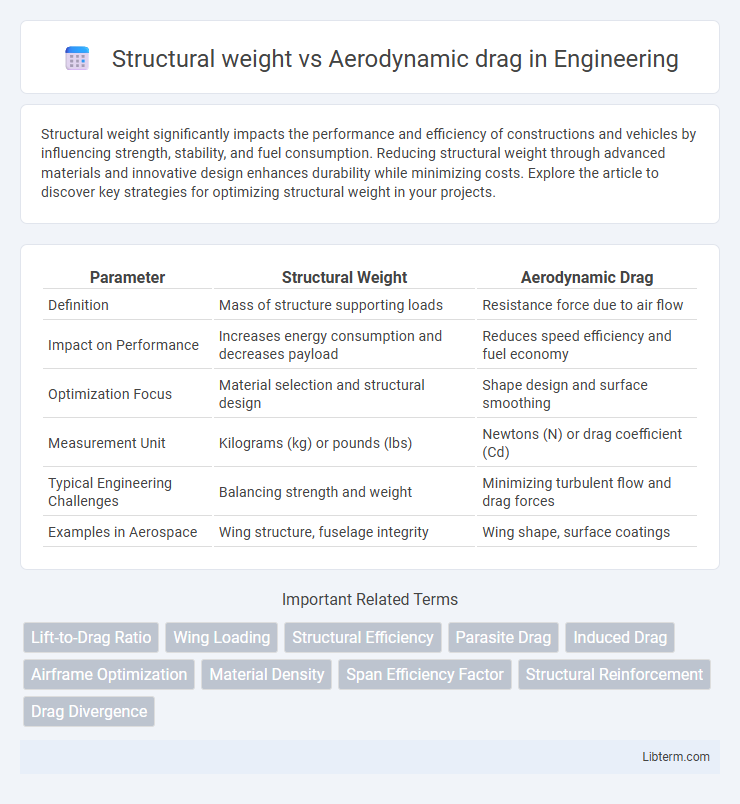

| Parameter | Structural Weight | Aerodynamic Drag |

|---|---|---|

| Definition | Mass of structure supporting loads | Resistance force due to air flow |

| Impact on Performance | Increases energy consumption and decreases payload | Reduces speed efficiency and fuel economy |

| Optimization Focus | Material selection and structural design | Shape design and surface smoothing |

| Measurement Unit | Kilograms (kg) or pounds (lbs) | Newtons (N) or drag coefficient (Cd) |

| Typical Engineering Challenges | Balancing strength and weight | Minimizing turbulent flow and drag forces |

| Examples in Aerospace | Wing structure, fuselage integrity | Wing shape, surface coatings |

Understanding Structural Weight in Aircraft Design

Structural weight in aircraft design directly influences aerodynamic efficiency by determining the aircraft's overall mass and balance, which affects lift and drag characteristics. Engineers prioritize lightweight materials such as composites and aluminum alloys to minimize structural weight, thus enhancing fuel efficiency and performance. Achieving an optimal balance between structural integrity and weight reduction is crucial for reducing aerodynamic drag and improving operational range.

The Fundamentals of Aerodynamic Drag

Aerodynamic drag fundamentally arises from the resistance air exerts on a moving object, influenced by factors such as shape, surface roughness, and flow velocity. Structural weight directly impacts drag because heavier structures often require larger support surfaces, increasing the frontal area and thus increasing drag coefficients. Minimizing structural weight helps reduce drag by allowing sleeker, more streamlined designs that improve overall aerodynamic efficiency and fuel consumption.

The Interplay Between Weight and Drag

Structural weight directly impacts aerodynamic drag by influencing the aircraft's lift requirements, as heavier structures demand more lift, increasing induced drag. The trade-off between minimizing structural weight and maintaining sufficient strength affects the overall drag profile, where lighter materials can reduce weight but may compromise aerodynamic smoothness. Optimizing this interplay involves balancing material choices and design geometry to achieve the lowest total drag while ensuring structural integrity.

Design Trade-offs: Reducing Weight vs Minimizing Drag

Design trade-offs between structural weight and aerodynamic drag play a critical role in aerospace engineering, as reducing structural weight often demands thinner or fewer materials, potentially compromising aerodynamic smoothness and increasing drag. Optimizing aircraft design requires balancing lightweight composite materials and reinforcement techniques against aerodynamic shaping to achieve fuel efficiency and performance goals. Engineers utilize computational fluid dynamics and finite element analysis to analyze these competing factors, ensuring the structure maintains integrity while minimizing drag-induced energy loss.

Material Selection Impact on Structural Weight

Material selection plays a critical role in reducing structural weight, which directly influences aerodynamic drag by enabling sleeker, more efficient aircraft designs. Advanced composites like carbon fiber-reinforced polymers offer high strength-to-weight ratios, significantly decreasing structural mass while maintaining durability. Lightweight materials allow for optimized aerodynamic shapes that minimize drag, improving overall fuel efficiency and performance.

Aerodynamic Shaping and Its Effect on Drag

Aerodynamic shaping significantly reduces drag by streamlining the vehicle's exterior to minimize air resistance, which directly impacts fuel efficiency and speed. Optimizing the contour and surface smoothness improves airflow, decreasing turbulent wake and pressure drag. This reduction in aerodynamic drag often allows designers to balance structural weight with enhanced performance without compromising safety or durability.

Fuel Efficiency: Balancing Weight and Drag

Reducing structural weight in aircraft design enhances fuel efficiency by lowering lift-induced drag and improving payload capacity. However, excessive weight reduction can compromise structural integrity, leading to increased aerodynamic drag due to design limitations. Optimizing the balance between lightweight materials and aerodynamic shapes minimizes total drag, resulting in significant fuel savings and improved operational performance.

Advances in Lightweight Structures

Advances in lightweight structures have revolutionized the balance between structural weight and aerodynamic drag, enabling aircraft to achieve higher fuel efficiency and enhanced performance. Innovative materials such as carbon fiber composites and titanium alloys reduce structural weight without compromising strength, thereby decreasing drag and improving lift-to-drag ratios. Integration of topology optimization and additive manufacturing techniques further refines component designs, minimizing weight while maximizing aerodynamic effectiveness.

Innovative Techniques for Drag Reduction

Innovative techniques for drag reduction focus on minimizing both structural weight and aerodynamic drag to enhance performance and fuel efficiency in aerospace and automotive industries. Advanced materials like carbon fiber composites decrease structural weight without compromising strength, while active flow control methods, such as boundary layer suction and plasma actuators, effectively reduce aerodynamic drag. Computational fluid dynamics (CFD) optimization and biomimetic surface designs further refine aerodynamic profiles, achieving substantial drag reduction while maintaining structural integrity.

Future Trends in Weight vs Drag Optimization

Future trends in weight versus aerodynamic drag optimization emphasize advanced composite materials like carbon fiber and graphene to reduce structural weight without compromising strength. Integration of additive manufacturing techniques enables complex, lightweight geometries that minimize drag by improving surface smoothness and aerodynamic efficiency. Computational fluid dynamics (CFD) combined with machine learning algorithms further refines designs, balancing weight reduction and drag minimization for enhanced fuel efficiency and performance in aerospace and automotive industries.

Structural weight Infographic

libterm.com

libterm.com