Differential action ensures precise control by responding only to the difference between two input signals, minimizing errors caused by common-mode noise or interference. It enhances the accuracy and stability of systems like amplifiers and control circuits used in industrial applications. Explore the rest of the article to understand how differential action can improve your system's performance.

Table of Comparison

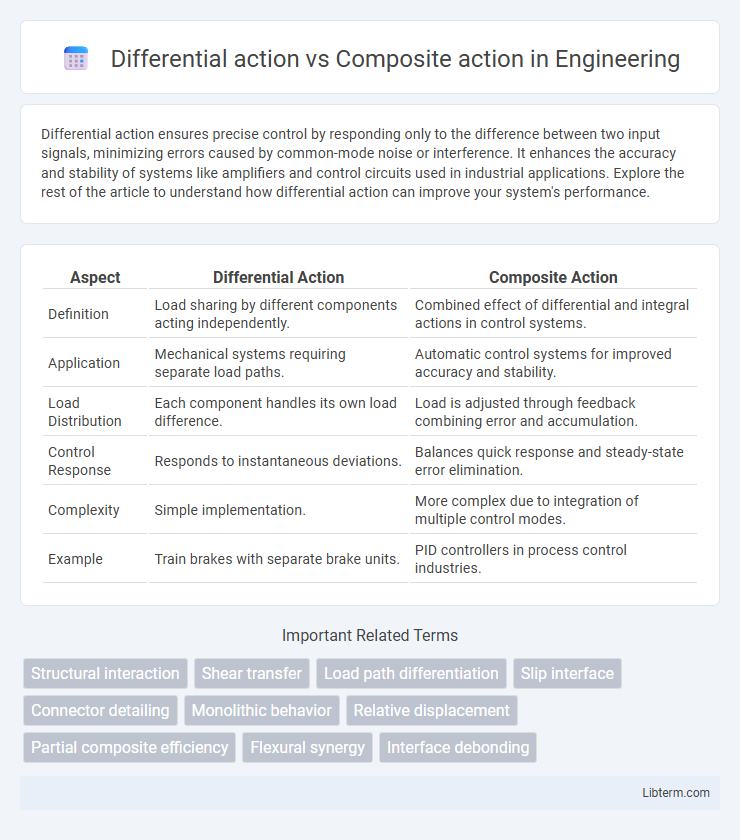

| Aspect | Differential Action | Composite Action |

|---|---|---|

| Definition | Load sharing by different components acting independently. | Combined effect of differential and integral actions in control systems. |

| Application | Mechanical systems requiring separate load paths. | Automatic control systems for improved accuracy and stability. |

| Load Distribution | Each component handles its own load difference. | Load is adjusted through feedback combining error and accumulation. |

| Control Response | Responds to instantaneous deviations. | Balances quick response and steady-state error elimination. |

| Complexity | Simple implementation. | More complex due to integration of multiple control modes. |

| Example | Train brakes with separate brake units. | PID controllers in process control industries. |

Introduction to Differential Action and Composite Action

Differential action refers to a control mechanism where the response is based on the difference between two input signals, commonly used in systems requiring precise error correction, such as in differential amplifiers or automatic control loops. Composite action combines multiple types of control strategies--typically proportional, integral, and derivative actions--into a single control system to optimize performance by balancing stability, speed, and accuracy. Understanding differential and composite action is essential in designing advanced controllers for industrial automation, robotics, and process engineering.

Definition of Differential Action

Differential action refers to the control mechanism where the output response is proportional to the rate of change of the error signal, emphasizing rapid reaction to error fluctuations to improve system stability. This contrasts with composite action, which combines proportional, integral, and differential responses to achieve balanced control. Differential action is particularly effective in minimizing overshoot and oscillations in dynamic systems by addressing the error trend rather than its magnitude alone.

Definition of Composite Action

Composite action refers to the structural behavior when two or more different materials or structural elements, such as steel and concrete, act together to resist loads, resulting in enhanced strength and stiffness compared to individual components alone. This synergy occurs through effective load transfer mechanisms such as shear connectors, ensuring the composite section behaves as a single unit under applied forces. Differentiating from differential action, where materials act independently, composite action maximizes overall structural efficiency and durability in construction engineering.

Key Principles of Differential Action

Differential action primarily relies on the principle of comparing two input signals to detect changes, enhancing sensitivity to differences while rejecting common-mode signals, which improves noise immunity in control systems. It utilizes the difference between measured variables, enabling precise fault detection and reducing false alarms. This key principle ensures that only differential changes trigger responses, distinguishing it from composite action, which combines multiple input signals without isolating their differences.

Key Principles of Composite Action

Composite action harnesses the combined strengths of steel and concrete to resist applied loads, maximizing structural efficiency through effective load transfer mechanisms. Key principles include ensuring compatibility of deformations between materials, utilizing shear connectors to prevent slip at the interface, and optimizing cross-sectional interaction to exploit both materials' tensile and compressive capacities. Differential action contrasts by treating components independently, leading to reduced performance compared to the synergistic behavior foundational to composite action.

Comparative Analysis: Differential vs Composite Action

Differential action relies on the difference between two input signals to generate an output, offering high precision and noise cancellation, ideal for sensitive measurements. Composite action combines multiple control strategies, such as proportional, integral, and derivative, into a unified system to enhance overall process stability and responsiveness. Differential action excels in situations requiring error minimization through signal comparison, whereas composite action provides versatile control by addressing multiple dynamics simultaneously.

Applications in Engineering and Mechanics

Differential action involves the relative displacement between components, commonly applied in control systems and mechanical linkages to achieve precise motion or force regulation. Composite action combines multiple material or structural elements to enhance overall strength and stiffness, widely used in beam design and reinforced concrete structures. Engineering applications leverage differential action for responsive control mechanisms, while composite action is critical in optimizing load distribution and durability in mechanical assemblies.

Advantages and Disadvantages of Differential Action

Differential action in control systems offers the advantage of responding to the rate of change of the error signal, which improves system stability and reduces overshoot in transient response. However, it is highly sensitive to measurement noise, leading to potential amplification of high-frequency disturbances and erratic control behavior. Despite its ability to enhance system performance, differential action requires careful tuning and filtering to avoid instability caused by noise amplification.

Advantages and Disadvantages of Composite Action

Composite action combines steel and concrete elements to optimize structural performance, offering advantages such as increased load-carrying capacity, improved stiffness, and better material efficiency. It enhances durability and reduces overall construction costs by utilizing the strengths of both materials while minimizing weight. However, composite action may require more complex design and construction techniques, potential issues with differential settlement, and careful consideration of load transfer mechanisms between materials.

Summary and Future Perspectives

Differential action isolates and responds to changes in individual signals, providing precise control in dynamic systems, while composite action combines multiple control strategies to enhance overall system stability and performance. Advances in artificial intelligence and machine learning promise to integrate differential and composite actions more effectively, enabling adaptive and predictive control mechanisms. Future research will likely focus on optimizing hybrid control algorithms and improving real-time system responsiveness across industrial and robotic applications.

Differential action Infographic

libterm.com

libterm.com