Precision balancing enhances the performance and longevity of rotating machinery by minimizing vibrations and preventing premature wear. This process involves carefully adjusting the mass distribution to ensure smooth and efficient operation. Explore the article to learn how precision balancing can improve your equipment's reliability and efficiency.

Table of Comparison

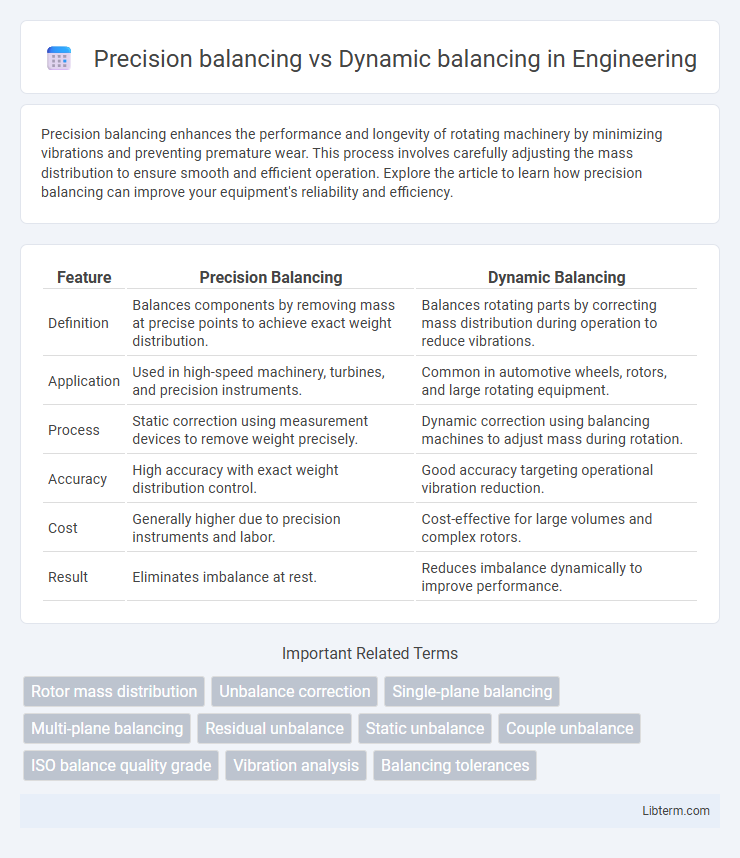

| Feature | Precision Balancing | Dynamic Balancing |

|---|---|---|

| Definition | Balances components by removing mass at precise points to achieve exact weight distribution. | Balances rotating parts by correcting mass distribution during operation to reduce vibrations. |

| Application | Used in high-speed machinery, turbines, and precision instruments. | Common in automotive wheels, rotors, and large rotating equipment. |

| Process | Static correction using measurement devices to remove weight precisely. | Dynamic correction using balancing machines to adjust mass during rotation. |

| Accuracy | High accuracy with exact weight distribution control. | Good accuracy targeting operational vibration reduction. |

| Cost | Generally higher due to precision instruments and labor. | Cost-effective for large volumes and complex rotors. |

| Result | Eliminates imbalance at rest. | Reduces imbalance dynamically to improve performance. |

Introduction to Balancing Techniques

Precision balancing involves measuring and correcting imbalances in rotating components with extremely high accuracy, often used for high-speed machinery where even minor imbalances can cause significant vibration and wear. Dynamic balancing focuses on balancing the rotating parts during operation by identifying and compensating for imbalances in multiple planes to ensure smooth rotation. Both techniques utilize specialized equipment like balancing machines and sensors, but precision balancing targets static and overall balance, whereas dynamic balancing addresses imbalance under operational conditions.

Defining Precision Balancing

Precision balancing involves accurately measuring and correcting mass distribution on rotating components to minimize vibrations and extend machinery lifespan. It uses high-sensitivity instruments to detect subtle imbalances, ensuring components operate within tight tolerance levels. Dynamic balancing, by contrast, focuses on balancing parts in motion to counteract forces during rotation, often applied in high-speed applications like turbines or automotive wheels.

What Is Dynamic Balancing?

Dynamic balancing is a process that measures and corrects unbalance in rotating parts while they spin, ensuring smooth operation and reducing vibration at multiple rotational planes. Unlike precision balancing, which targets individual components with static conditions, dynamic balancing assesses the entire assembly in motion to optimize performance and extend machinery lifespan. This method is essential for high-speed equipment like turbines, motors, and automotive wheels where both angular and radial forces affect balance.

Key Differences Between Precision and Dynamic Balancing

Precision balancing targets specific rotor components by measuring minute imbalances at known locations, primarily used for high-speed, low-mass components requiring exact corrections. Dynamic balancing involves measuring imbalances across multiple planes simultaneously while the rotor spins, suitable for larger, heavier rotors with complex mass distributions. Key differences include the scope of measurement, applicable rotor types, and the balance correction methods used, where precision balancing focuses on static corrections and dynamic balancing addresses multi-plane imbalances affecting operational stability.

Applications of Precision Balancing

Precision balancing is essential for high-speed and high-precision applications such as aerospace components, medical instruments, and advanced robotics, where minimal vibration and maximum accuracy are critical. It involves correcting even the smallest imbalances at sub-micron levels, ensuring optimal performance and longevity of vulnerable, high-value parts. In contrast, dynamic balancing suits larger rotating machinery like turbines and automotive components, focusing on balancing at operational speeds to reduce wear and enhance efficiency.

Industrial Uses of Dynamic Balancing

Dynamic balancing is essential in industrial applications to reduce vibrations and extend the lifespan of rotating machinery such as turbines, motors, and compressors. Unlike precision balancing, which primarily targets static imbalance, dynamic balancing addresses both static and dynamic imbalances that occur during high-speed rotations, ensuring smoother operation and improved efficiency. This process is critical in industries like automotive manufacturing, aerospace, and power generation, where equipment performance and reliability are paramount.

Benefits of Precision Balancing in Machinery

Precision balancing enhances machinery performance by minimizing vibrations and extending equipment lifespan through exact mass distribution corrections. It improves operational efficiency and reduces wear on critical components, leading to lower maintenance costs and downtime. This method ensures higher accuracy in rotating parts, critical for high-speed machinery applications requiring tight tolerance standards.

Advantages of Dynamic Balancing for Equipment Longevity

Dynamic balancing offers superior advantages for equipment longevity by correcting imbalances in rotating components during actual operational speeds, reducing vibration and wear on bearings and shafts. This precise adjustment minimizes mechanical stress, extends service intervals, and enhances overall machine reliability compared to static or precision balancing done off-rotation. As a result, dynamic balancing directly contributes to prolonged equipment life and reduced maintenance costs in industrial applications.

Factors to Consider When Choosing a Balancing Method

Precision balancing requires high accuracy for components operating at high speeds or with tight tolerances, making it ideal for aerospace and high-performance industrial applications. Dynamic balancing addresses rotational imbalances in assemblies by measuring vibration levels during operation, suitable for automotive and large rotating machinery. Factors to consider include the component's operational speed, tolerance requirements, cost constraints, and the specific imbalance type to ensure optimal performance and longevity.

Summary: Choosing the Right Balancing Solution

Precision balancing ensures high accuracy by correcting imbalances with minimal tolerance, ideal for applications in aerospace and high-speed machinery. Dynamic balancing addresses imbalance during operation, optimizing performance in rotating components such as automotive wheels and industrial turbines. Selecting the right balancing solution depends on factors like rotational speed, precision requirements, and application-specific tolerance levels.

Precision balancing Infographic

libterm.com

libterm.com