Two-way slabs efficiently distribute loads in both directions, enhancing structural stability and reducing material usage in construction projects. They are ideal for medium to heavy load applications such as commercial buildings and parking garages due to their ability to span larger areas with fewer supports. Discover how two-way slabs can optimize your building design by reading the full article.

Table of Comparison

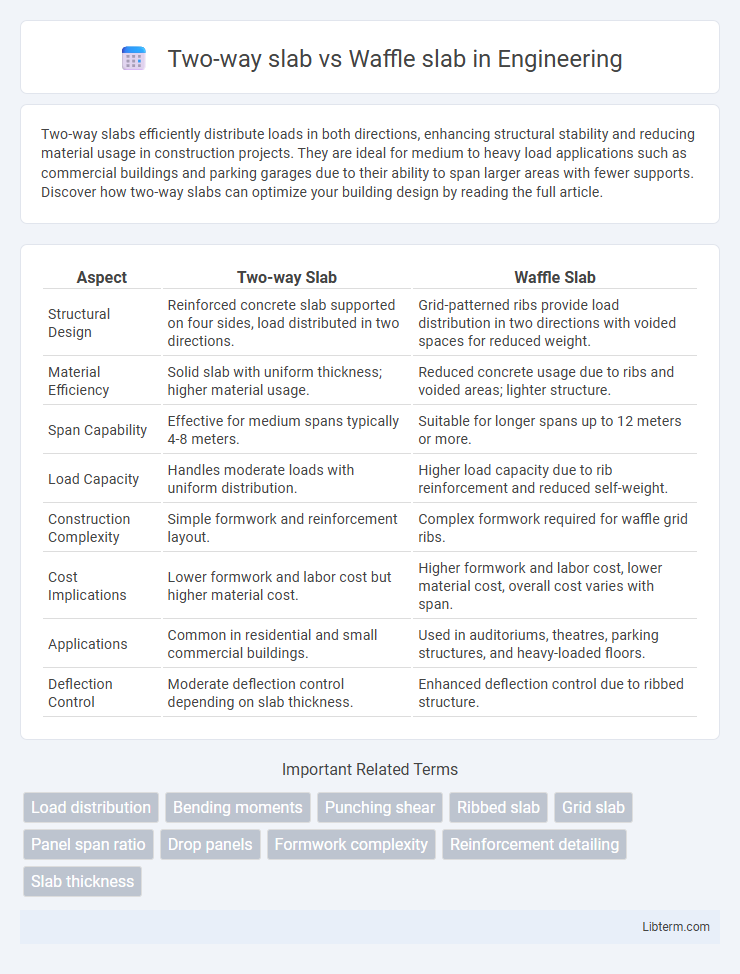

| Aspect | Two-way Slab | Waffle Slab |

|---|---|---|

| Structural Design | Reinforced concrete slab supported on four sides, load distributed in two directions. | Grid-patterned ribs provide load distribution in two directions with voided spaces for reduced weight. |

| Material Efficiency | Solid slab with uniform thickness; higher material usage. | Reduced concrete usage due to ribs and voided areas; lighter structure. |

| Span Capability | Effective for medium spans typically 4-8 meters. | Suitable for longer spans up to 12 meters or more. |

| Load Capacity | Handles moderate loads with uniform distribution. | Higher load capacity due to rib reinforcement and reduced self-weight. |

| Construction Complexity | Simple formwork and reinforcement layout. | Complex formwork required for waffle grid ribs. |

| Cost Implications | Lower formwork and labor cost but higher material cost. | Higher formwork and labor cost, lower material cost, overall cost varies with span. |

| Applications | Common in residential and small commercial buildings. | Used in auditoriums, theatres, parking structures, and heavy-loaded floors. |

| Deflection Control | Moderate deflection control depending on slab thickness. | Enhanced deflection control due to ribbed structure. |

Introduction to Two-Way Slab and Waffle Slab

Two-way slabs distribute loads in two directions, supported by beams or columns, providing efficient load transfer for rectangular or square spans. Waffle slabs feature a grid of ribs beneath the slab surface, reducing weight and enhancing structural rigidity while allowing longer spans with minimal material use. Both systems optimize concrete usage and structural performance, with two-way slabs preferred for uniform loading and waffle slabs ideal for heavier loads and architectural aesthetics.

Key Differences Between Two-Way Slab and Waffle Slab

Two-way slabs distribute loads in both directions using a flat, uniform thickness, making them suitable for medium spans with moderate load requirements, while waffle slabs feature a grid of ribs that reduce weight and increase strength, ideal for longer spans and heavier loads. Two-way slabs provide a smooth ceiling finish without additional formwork, whereas waffle slabs require complex formwork but offer better mechanical and acoustic insulation due to their ribbed structure. The choice depends on structural performance, cost considerations, and architectural requirements, with waffle slabs often used in large commercial buildings and two-way slabs in residential or light commercial projects.

Structural Behavior and Load Distribution

Two-way slabs distribute loads in two directions, providing efficient support over square or nearly square spans by transferring loads to all four edges, resulting in balanced bending moments and reduced deflections. Waffle slabs feature a grid of beams beneath the slab, enhancing stiffness and load-carrying capacity while reducing slab thickness and weight, ideal for longer spans with concentrated loads. Structural behavior of waffle slabs demonstrates superior moment resistance and minimized deflections compared to two-way slabs due to the ribbed beam system enhancing load distribution and structural rigidity.

Material Efficiency and Cost Considerations

Two-way slabs offer material efficiency by distributing loads in both directions, reducing the amount of concrete and steel required compared to one-way slabs, but waffle slabs further enhance efficiency through their ribbed grid design that minimizes concrete use while maintaining structural strength. Waffle slabs are often more expensive to construct due to complex formwork and labor-intensive processes, whereas two-way slabs have lower upfront costs but may use more materials overall. Cost considerations must balance the initial construction expenses against long-term benefits of reduced material consumption and structural performance.

Construction Methods and Techniques

Two-way slabs are constructed using a grid of beams or drop panels supporting the slab, with reinforcement distributed in both directions to handle loads evenly, typically cast in place with formwork and temporary shoring. Waffle slabs require a complex mold system with ribbed falsework or metal forms creating a waffle-like underside, reducing material use while increasing structural depth and strength, generally cast in situ or prefabricated for rapid installation. Both methods use reinforced concrete but differ significantly in formwork complexity, material efficiency, and load distribution techniques.

Applications and Suitable Use Cases

Two-way slabs are ideal for rectangular floor layouts with uniform load distribution, commonly used in residential buildings and commercial spaces requiring moderate spans. Waffle slabs provide enhanced structural strength and stiffness, making them suitable for large-span areas like auditoriums, parking garages, and industrial facilities where load-bearing efficiency and reduced weight are critical. Both slab types optimize material use but differ in application based on span requirements and architectural design complexity.

Advantages of Two-Way Slabs

Two-way slabs offer enhanced load distribution, allowing them to support heavier loads over larger spans compared to waffle slabs. Their simpler formwork and reduced construction time result in cost-efficiency while maintaining structural integrity. Additionally, two-way slabs provide better resistance to bending moments along both directions, making them ideal for buildings requiring uniform strength and stiffness.

Advantages of Waffle Slabs

Waffle slabs offer superior load distribution due to their ribbed design, which enhances structural strength while reducing material usage compared to two-way slabs. Their lightweight nature allows for longer spans and greater design flexibility, making them ideal for large commercial or institutional buildings. Additionally, waffle slabs improve acoustic insulation and provide an aesthetically pleasing ceiling finish without requiring additional false ceilings.

Limitations and Challenges

Two-way slabs face limitations in spanning large areas without intermediate supports, leading to increased thickness and material usage. Waffle slabs challenge construction complexity due to the formwork required for their ribbed pattern, impacting labor costs and time. Both systems require careful design to address deflection and load distribution, with waffle slabs offering better load-bearing efficiency but higher initial construction difficulty.

Conclusion: Choosing the Right Slab System

Two-way slabs offer uniform load distribution and are ideal for moderate spans with relatively simple formwork, whereas waffle slabs provide greater strength and rigidity, making them suitable for longer spans and heavier loads. Considering factors such as project budget, load requirements, and architectural aesthetics is crucial when selecting between these slab systems. Optimal slab choice enhances structural performance while balancing construction efficiency and cost-effectiveness.

Two-way slab Infographic

libterm.com

libterm.com