Extrusion is a manufacturing process that forces material through a shaped die to create objects with a fixed cross-sectional profile, commonly used for metals, plastics, and ceramics. This technique offers high precision and efficiency, making it ideal for producing pipes, sheets, and complex profiles while reducing material waste. Discover how extrusion can optimize your production needs and explore its various applications in the full article.

Table of Comparison

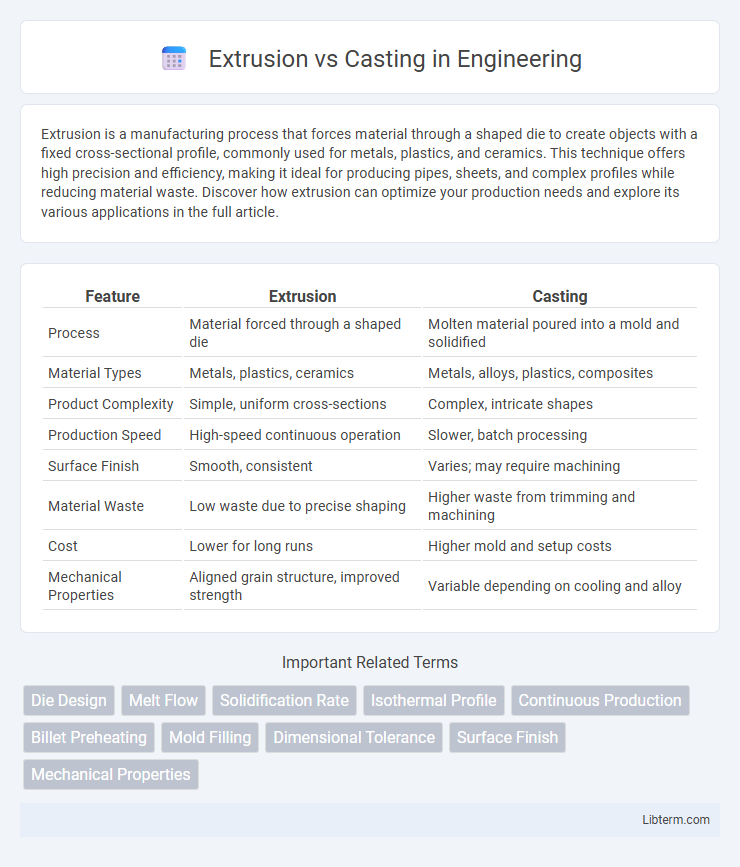

| Feature | Extrusion | Casting |

|---|---|---|

| Process | Material forced through a shaped die | Molten material poured into a mold and solidified |

| Material Types | Metals, plastics, ceramics | Metals, alloys, plastics, composites |

| Product Complexity | Simple, uniform cross-sections | Complex, intricate shapes |

| Production Speed | High-speed continuous operation | Slower, batch processing |

| Surface Finish | Smooth, consistent | Varies; may require machining |

| Material Waste | Low waste due to precise shaping | Higher waste from trimming and machining |

| Cost | Lower for long runs | Higher mold and setup costs |

| Mechanical Properties | Aligned grain structure, improved strength | Variable depending on cooling and alloy |

Introduction to Extrusion and Casting

Extrusion is a manufacturing process where material is forced through a shaped die to create objects with a fixed cross-sectional profile, commonly used for metals, plastics, and ceramics. Casting involves pouring molten material into a mold where it solidifies into the desired shape, ideal for complex geometries and large components in metals and alloys. Both processes are fundamental in industrial production, with extrusion emphasizing continuous shapes and casting prioritizing intricate designs.

Overview of the Extrusion Process

The extrusion process involves forcing heated material, typically metals or plastics, through a shaped die to create continuous profiles with consistent cross-sections. This method allows for precise control over dimensions and surface finishes, making it ideal for manufacturing complex shapes like pipes, rods, and structural components. Extrusion offers advantages such as high production speed, reduced material waste, and excellent mechanical properties due to the material's directional grain structure.

Overview of the Casting Process

The casting process involves pouring molten metal into a mold where it solidifies into a specific shape, making it ideal for complex geometries and large components. This process offers high versatility, enabling the production of intricate parts with fine details, often used in automotive, aerospace, and industrial applications. Compared to extrusion, casting allows for greater design freedom but typically requires longer cooling times and can result in porosity or surface imperfections if not carefully controlled.

Key Differences Between Extrusion and Casting

Extrusion involves forcing molten material through a shaped die to create objects with a fixed cross-sectional profile, offering high precision and uniformity in dimensions. Casting pours molten material into a mold where it solidifies, enabling complex shapes but often requiring more post-processing to achieve fine details or surface finish. Extrusion is ideal for continuous lengths of uniform cross-section, while casting excels at producing intricate or bulky components with varied geometries.

Material Compatibility in Extrusion vs Casting

Extrusion excels with materials like aluminum, copper, and certain thermoplastics that have high malleability and consistency, enabling continuous shaping with uniform cross-sections. Casting tolerates a broader range of metals, including cast iron, steel, and complex alloys, suitable for intricate geometries and varying thicknesses but may require post-processing to improve material properties. Material compatibility in extrusion favors ductile metals and polymers with stable viscosity, while casting accommodates diverse materials that solidify from molten states, influencing the choice based on project specifications.

Advantages of Extrusion

Extrusion offers superior material strength and uniformity compared to casting due to continuous pressure applied during the process, resulting in fewer defects and enhanced mechanical properties. This method allows for complex cross-sectional shapes and tighter dimensional tolerances, making it ideal for producing lightweight, high-strength components in industries like aerospace and automotive. Extrusion also supports faster production rates and better surface finishes, reducing post-processing costs and increasing manufacturing efficiency.

Advantages of Casting

Casting offers superior design flexibility, allowing the creation of complex shapes and intricate geometries that are difficult to achieve through extrusion. It provides excellent material variety, accommodating metals and alloys with diverse properties for tailored applications. Additionally, casting enables the production of large components with uniform mechanical properties, making it ideal for heavy-duty industrial parts.

Typical Applications of Extrusion and Casting

Extrusion is commonly used for manufacturing complex cross-sectional profiles such as window frames, pipes, and automotive components, where uniformity and strength are critical. Casting is typically applied to produce intricate shapes like engine blocks, sculptures, and large industrial machine parts due to its capability to form complex geometries with varied thicknesses. Each process suits different industries, with extrusion favored in construction and automotive sectors, while casting dominates aerospace, automotive, and art production.

Cost Considerations: Extrusion vs Casting

Extrusion typically offers lower production costs for high-volume runs due to its continuous process and efficient material usage, reducing waste and energy consumption compared to casting. Casting incurs higher initial setup costs related to mold creation and longer cycle times, making it less cost-effective for small batches or complex shapes with tight tolerances. Choosing between extrusion and casting depends on balancing the production volume, desired material properties, and precision requirements to optimize overall manufacturing expenses.

Choosing the Right Process for Your Project

Selecting the right manufacturing process between extrusion and casting depends on factors like material type, design complexity, and production volume. Extrusion is ideal for creating uniform cross-sectional profiles with high strength and excellent surface finish, commonly used for metals like aluminum and plastics. Casting suits complex geometries and large parts, offering design flexibility and cost efficiency for low to medium production runs, often utilizing metals such as iron, steel, and aluminum alloys.

Extrusion Infographic

libterm.com

libterm.com