A bow is a flexible weapon designed to launch arrows with precision and power, commonly used in hunting and archery sports. Its design balances tension and elasticity, enabling arrows to travel great distances accurately. Discover how mastering the bow can enhance your skills by exploring the full article.

Table of Comparison

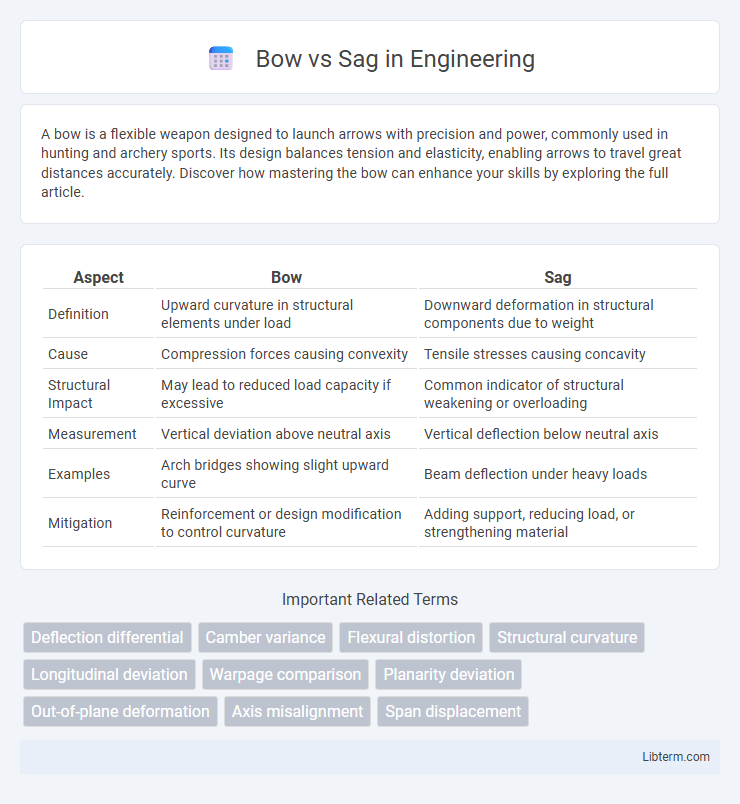

| Aspect | Bow | Sag |

|---|---|---|

| Definition | Upward curvature in structural elements under load | Downward deformation in structural components due to weight |

| Cause | Compression forces causing convexity | Tensile stresses causing concavity |

| Structural Impact | May lead to reduced load capacity if excessive | Common indicator of structural weakening or overloading |

| Measurement | Vertical deviation above neutral axis | Vertical deflection below neutral axis |

| Examples | Arch bridges showing slight upward curve | Beam deflection under heavy loads |

| Mitigation | Reinforcement or design modification to control curvature | Adding support, reducing load, or strengthening material |

Introduction: Understanding Bow and Sag

Bow and sag refer to the deformation patterns in structural elements under load, critical for assessing material performance and safety. Bow describes a convex curvature along the length, often seen in beams subjected to bending moments. Sag indicates a concave downward displacement, commonly observed in suspended cables or roofs, influencing load distribution and stability.

Defining Bow and Sag in Context

Bow and sag refer to vertical deviations in structural elements under load, where bow indicates an outward curve and sag implies a downward deflection. Bow commonly occurs in beams or walls due to lateral pressure, while sag typically appears in beams or joists under gravity loads. Assessing bow and sag accurately helps ensure structural integrity and serviceability in construction and engineering projects.

Causes of Bow Versus Causes of Sag

Bow typically occurs due to thermal expansion, moisture absorption, or uneven weight distribution causing a board or panel to curve outward along its length. Sag results from prolonged loading or insufficient support, leading to a downward curvature or deflection under gravity. Material properties, such as elasticity and thickness, also influence whether an object experiences bowing or sagging under specific conditions.

Effects of Bow and Sag on Materials

Bow causes materials to curve along their length, resulting in uneven stress distribution and potential warping, which can reduce structural integrity and cause alignment issues in assemblies. Sag leads to downward deflection due to gravitational or load-induced forces, promoting permanent deformation and accelerated fatigue, particularly in unsupported spans. Both bow and sag compromise material performance by altering load paths and inducing internal stresses that may lead to cracks, reduced lifespan, and failure under operational conditions.

Detection and Measurement Techniques

Bow and sag in structural components are detected using laser scanning and photogrammetry for high-precision surface mapping, enabling accurate measurement of deviations from the intended geometry. Strain gauges and digital image correlation (DIC) techniques provide quantitative data on deformation and displacement under load, enhancing the reliability of bow and sag assessments. Non-contact ultrasonic testing and 3D coordinate measurement machines (CMM) are also employed to precisely evaluate the extent and location of bowing or sagging in materials.

Common Industries Affected by Bow and Sag

Bow and sag frequently impact construction, manufacturing, and transportation industries due to their effects on structural integrity. In construction, bowed beams can compromise building stability, while sagging rails or conveyor belts in manufacturing disrupt operational efficiency. Transportation sectors experience challenges from sagging bridges or tracks, leading to safety hazards and increased maintenance costs.

Prevention and Correction Methods

Prevention of bow and sag in structures involves selecting high-strength materials and ensuring proper load distribution during design and construction. Correction methods for bow include reinforcing with steel braces or applying tension cables, while sag is typically addressed by adding supports or jacking to restore alignment. Regular inspections and timely maintenance play crucial roles in detecting early signs and preventing extensive damage.

Comparative Analysis: Bow vs Sag

Bow and sag are critical defects in materials and structures, with bow referring to curvature along the length, while sag denotes downward displacement due to gravity or load. In comparative analysis, bow often results from internal stresses or manufacturing inconsistencies, whereas sag primarily arises from external forces, influencing stability and alignment differently. Understanding these distinctions is vital for engineers to select appropriate corrective measures, including reinforcement or realignment techniques, ensuring structural integrity and functionality.

Practical Examples and Case Studies

Bow and sag represent common structural deformations in beams subjected to different loading conditions, with bow indicating a curved upward deflection and sag showing a downward bending. Practical examples include bridges where excessive sag can compromise safety, while bow is often observed in wooden beams exposed to moisture, causing warping. Case studies from civil engineering projects demonstrate that monitoring sag through deflection sensors helps maintain structural integrity, whereas bow corrections frequently involve material replacement or reinforcement to restore original shape.

Key Takeaways and Best Practices

Bow and Sag distortions critically impact structural integrity and alignment in construction and manufacturing. Key takeaways highlight the importance of precise material selection, controlled loading conditions, and regular monitoring to prevent deformation. Best practices include implementing proper support systems, using advanced modeling software for stress analysis, and adhering to strict quality control standards throughout fabrication and installation.

Bow Infographic

libterm.com

libterm.com