Casting is a vital process in manufacturing where molten material is poured into a mold to create complex shapes with precision and efficiency. This technique is widely used in industries such as automotive, aerospace, and art to produce metal, plastic, and ceramic parts. Discover the essential methods and benefits of casting by exploring the rest of this article.

Table of Comparison

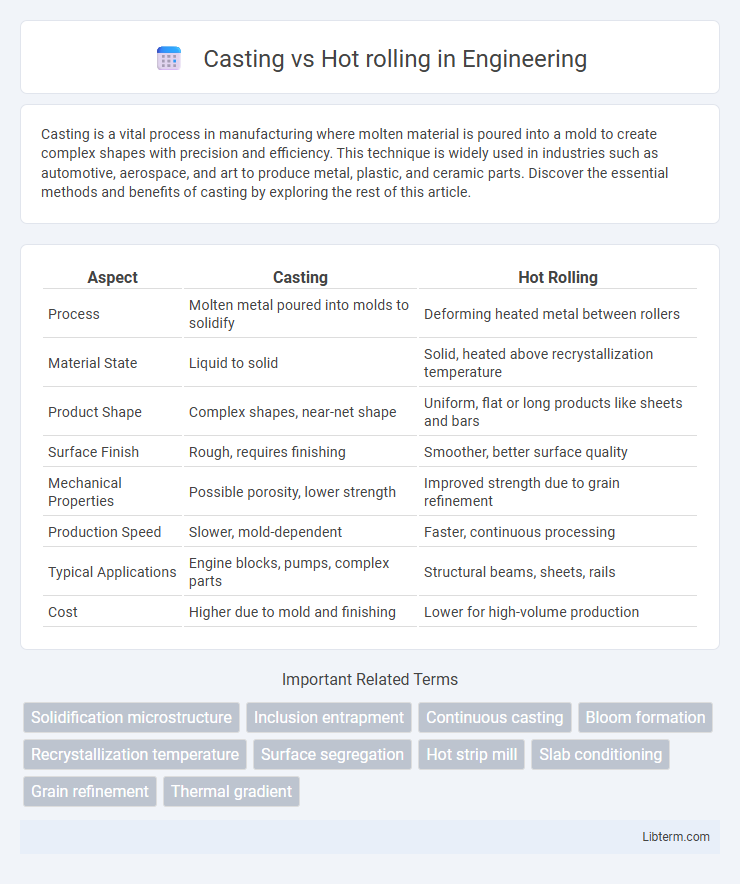

| Aspect | Casting | Hot Rolling |

|---|---|---|

| Process | Molten metal poured into molds to solidify | Deforming heated metal between rollers |

| Material State | Liquid to solid | Solid, heated above recrystallization temperature |

| Product Shape | Complex shapes, near-net shape | Uniform, flat or long products like sheets and bars |

| Surface Finish | Rough, requires finishing | Smoother, better surface quality |

| Mechanical Properties | Possible porosity, lower strength | Improved strength due to grain refinement |

| Production Speed | Slower, mold-dependent | Faster, continuous processing |

| Typical Applications | Engine blocks, pumps, complex parts | Structural beams, sheets, rails |

| Cost | Higher due to mold and finishing | Lower for high-volume production |

Introduction to Casting and Hot Rolling

Casting involves pouring molten metal into a mold where it solidifies into a specific shape, allowing for complex geometries and large-scale production. Hot rolling heats metal above its recrystallization temperature, enabling deformation to desired thicknesses and enhancing mechanical properties through grain refinement. Both processes are fundamental in metal manufacturing, with casting offering shape versatility and hot rolling improving structural integrity.

Fundamental Differences Between Casting and Hot Rolling

Casting involves pouring molten metal into a mold to solidify into a specific shape, allowing complex geometries and internal cavities to be formed directly. Hot rolling processes heated metal ingots or slabs by passing them through rollers, refining the grain structure, improving mechanical properties, and enhancing surface finish while controlling dimensions. The fundamental difference lies in casting producing near-net-shape parts from liquid metal, whereas hot rolling reshapes solid metal by plastic deformation under high temperatures.

Overview of the Casting Process

The casting process involves pouring molten metal into a mold where it solidifies into a specific shape, enabling the production of complex geometries that are difficult to achieve with hot rolling. Key parameters in casting include mold design, cooling rate, and alloy composition, which significantly influence the mechanical properties and microstructure of the final product. Unlike hot rolling, casting allows for near-net-shape manufacturing, reducing the need for extensive machining and material waste.

Overview of the Hot Rolling Process

Hot rolling is a metalworking process where heated metal slabs or billets are passed through rollers to achieve desired thickness and shape. The process improves the metal's mechanical properties by altering its microstructure through controlled deformation at high temperatures, typically above 1,000degF (538degC). Hot rolling offers advantages like enhanced ductility, refined grain structure, and reduced internal stresses compared to casting, making it ideal for producing sheets, plates, and structural components.

Advantages of Casting

Casting offers precise control over complex shapes and intricate geometries that hot rolling cannot easily achieve, making it ideal for manufacturing components with detailed designs and internal cavities. It provides excellent versatility in material choices, allowing the use of alloys with specific properties tailored for performance in various industrial applications. Furthermore, casting reduces material waste by producing near-net-shape parts, minimizing the need for extensive machining and thereby lowering production costs.

Advantages of Hot Rolling

Hot rolling offers superior mechanical properties by refining grain structure and enhancing ductility, making it ideal for structural applications. The process provides improved surface finish and dimensional accuracy compared to casting, reducing the need for extensive machining. High production efficiency and lower costs in hot rolling further contribute to its widespread use in manufacturing metal products.

Key Limitations of Casting

Casting often faces key limitations such as porosity, which can lead to decreased structural integrity and increased risk of defects. Dimensional inaccuracies and surface roughness are common challenges, necessitating additional machining and finishing processes. Unlike hot rolling, which produces more uniform microstructures and improved mechanical properties, casting can result in segregation and inconsistent grain sizes, impacting overall material performance.

Key Limitations of Hot Rolling

Hot rolling faces key limitations including decreased dimensional accuracy compared to casting, as the high temperatures cause thermal expansion and surface oxidation that impact precision. The process also struggles with complex geometries due to the material's plastic deformation constraints, restricting intricate shapes achievable by casting. Furthermore, the surface finish quality of hot-rolled products is generally rougher, requiring additional processing steps to meet strict tolerances needed in critical applications.

Applications: When to Choose Casting or Hot Rolling

Casting is preferred for complex shapes, intricate designs, and large-scale components where dimensional accuracy is less critical, commonly used in automotive engine blocks and heavy machinery parts. Hot rolling is ideal for producing uniform, strong metal sheets, plates, and structural components, favored in construction, shipbuilding, and pipelines requiring enhanced mechanical properties. Selecting casting or hot rolling depends on the application's need for precision, mechanical strength, and production volume.

Conclusion: Selecting the Right Metal Forming Method

Casting offers superior design flexibility and is ideal for complex geometries and low-volume production, while hot rolling excels in producing high-strength, uniform metal sheets and structural components at scale. The choice between casting and hot rolling depends on factors such as material properties, desired mechanical performance, production volume, and cost-efficiency. Engineers must evaluate specific project requirements and manufacturing constraints to select the optimal metal forming method that balances quality, efficiency, and budget.

Casting Infographic

libterm.com

libterm.com