Fluidized bed coating is an advanced technique that enhances surface properties by suspending particles in a heated air stream, allowing uniform coating application on various materials. This method improves durability, adhesion, and corrosion resistance, making it ideal for industries such as pharmaceuticals, electronics, and manufacturing. Discover how fluidized bed coating can optimize your production process by exploring the detailed benefits and applications in the rest of this article.

Table of Comparison

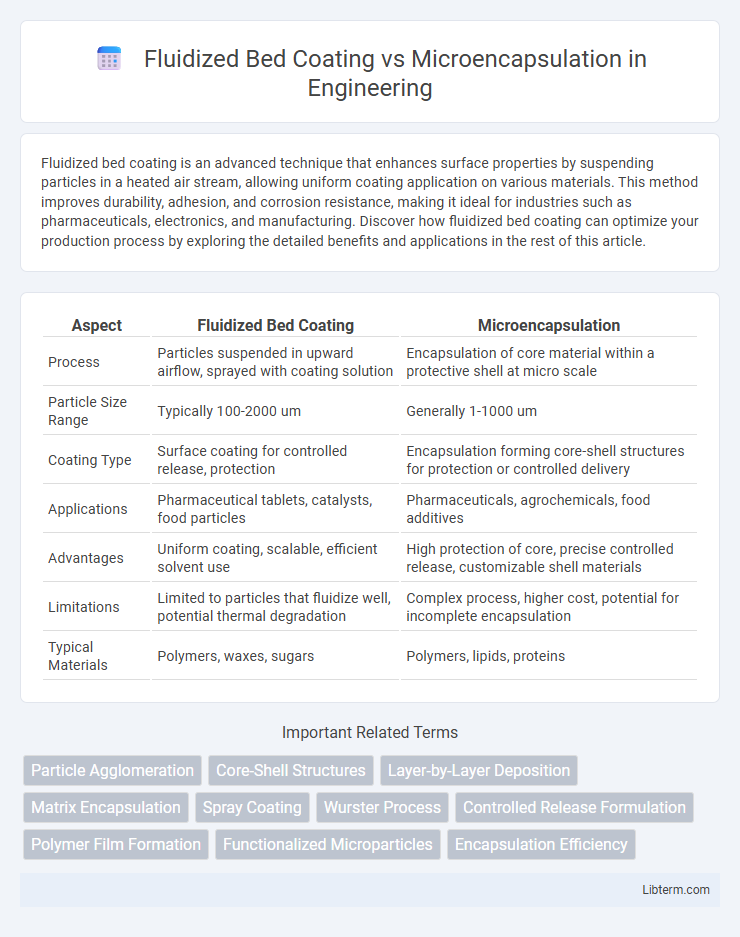

| Aspect | Fluidized Bed Coating | Microencapsulation |

|---|---|---|

| Process | Particles suspended in upward airflow, sprayed with coating solution | Encapsulation of core material within a protective shell at micro scale |

| Particle Size Range | Typically 100-2000 um | Generally 1-1000 um |

| Coating Type | Surface coating for controlled release, protection | Encapsulation forming core-shell structures for protection or controlled delivery |

| Applications | Pharmaceutical tablets, catalysts, food particles | Pharmaceuticals, agrochemicals, food additives |

| Advantages | Uniform coating, scalable, efficient solvent use | High protection of core, precise controlled release, customizable shell materials |

| Limitations | Limited to particles that fluidize well, potential thermal degradation | Complex process, higher cost, potential for incomplete encapsulation |

| Typical Materials | Polymers, waxes, sugars | Polymers, lipids, proteins |

Introduction to Fluidized Bed Coating and Microencapsulation

Fluidized bed coating involves suspending solid particles in an upward-flowing air stream to evenly apply a coating material, enhancing product stability and controlled release. Microencapsulation encapsulates active ingredients within a protective shell, improving handling, masking taste, and enabling targeted delivery. Both techniques are widely used in pharmaceuticals, food, and cosmetics to modify product properties and performance.

Overview of Fluidized Bed Coating Process

Fluidized bed coating involves suspending solid particles in a rising air stream to ensure uniform exposure and coating application. This process offers precise control over film thickness and coating composition, making it ideal for pharmaceuticals and food industries. Compared to microencapsulation, fluidized bed coating emphasizes surface modification rather than full particle encapsulation, enabling enhanced surface functionality and controlled release profiles.

Overview of Microencapsulation Techniques

Microencapsulation techniques include fluidized bed coating, spray drying, coacervation, and liposome entrapment, each offering unique advantages for controlled release and protection of active ingredients. Fluidized bed coating involves suspending particles in an upward air stream while spraying a coating solution, ensuring uniform layer formation and particle agglomeration prevention. This method excels in scalability and producing durable, uniform coatings suited for pharmaceuticals, food additives, and agrochemicals.

Key Differences in Coating Mechanisms

Fluidized Bed Coating uses a fluidizing gas to suspend particles, allowing a spray of coating material to uniformly cover each particle's surface, primarily relying on mechanical agitation and solvent evaporation for film formation. Microencapsulation encapsulates active ingredients within a polymeric shell or matrix, creating a distinct core-shell structure that isolates the core material from the environment. Key differences lie in fluidized bed's external surface coating versus microencapsulation's internal entrapment, affecting release profiles and protection levels of the active substances.

Material Compatibility and Applications

Fluidized bed coating excels in applying uniform polymer or wax layers on heat-sensitive particles, ensuring excellent material compatibility with pharmaceuticals and food-grade substances. Microencapsulation offers versatile encapsulation of active ingredients like vitamins, enzymes, and flavors, enhancing stability and controlled release in nutraceuticals and agriculture. Both methods serve distinct applications: fluidized bed coating is favored for sustained-release tablets and taste masking, while microencapsulation is preferred for protecting sensitive cores and targeted delivery in cosmetics and pesticides.

Particle Size and Morphology Control

Fluidized bed coating offers precise particle size and morphology control by allowing uniform application of coatings on core particles, resulting in consistent particle spheres and narrow size distribution. Microencapsulation typically produces particles with more variable morphology, often dependent on the encapsulation method, such as spray drying or coacervation, which may yield less uniform surface characteristics. Optimizing processing parameters in fluidized bed systems enhances coating thickness and particle sphericity, whereas microencapsulation emphasizes encapsulant material properties influencing particle size and shape variability.

Release Profile and Protection Efficiency

Fluidized bed coating offers precise control over the release profile by uniformly applying thin, consistent layers that enable targeted or sustained release of active agents, while microencapsulation enhances protection efficiency by encasing bioactives within a polymeric or lipid matrix that shields against environmental factors such as moisture, pH, and oxygen. Compared to microencapsulation, fluidized bed coating typically results in faster release rates due to thinner coatings, whereas microencapsulation provides superior protection efficiency by creating a more robust barrier for sensitive compounds. Selecting between the two methods depends on the required release kinetics and the degree of protection needed for the specific application.

Industrial Applications and Use Cases

Fluidized bed coating excels in pharmaceutical and food industries by providing uniform, durable coatings for tablets and granules, enhancing controlled release and protection. Microencapsulation is widely applied in agriculture, cosmetics, and food sectors for targeted delivery and controlled release of active ingredients like pesticides, fragrances, and vitamins. Industrial use cases highlight fluidized bed coating's efficiency in bulk processing, while microencapsulation offers versatility in encapsulating liquids, solids, or gases for improved stability and shelf life.

Advantages and Limitations of Each Method

Fluidized bed coating offers uniform particle coverage and efficient drying, making it ideal for controlled-release pharmaceuticals, but it is limited by higher equipment costs and sensitivity to particle size variations. Microencapsulation provides superior protection of active ingredients through encapsulating materials, enhancing stability and targeted delivery, though it often involves complex processes and higher production time. Both methods balance coating precision and production scalability, requiring careful selection based on product requirements and process constraints.

Choosing the Right Technology for Your Needs

Fluidized bed coating offers efficient uniform coating for tablets and pellets, ideal for controlled release and aesthetic enhancement, while microencapsulation provides precise encapsulation of active ingredients, improving stability and targeted delivery. Selecting the right technology depends on factors such as the release profile desired, protection requirements of the core material, and production scale. Evaluating formulation compatibility and cost-effectiveness ensures optimal performance aligned with pharmaceutical or food industry needs.

Fluidized Bed Coating Infographic

libterm.com

libterm.com