Composite materials combine two or more distinct substances to create a product with superior strength, durability, and lightweight properties ideal for various industries such as aerospace and construction. Their ability to be tailored to specific applications makes them essential for enhancing performance and efficiency. Explore the rest of this article to discover how composite materials can transform your next project or product design.

Table of Comparison

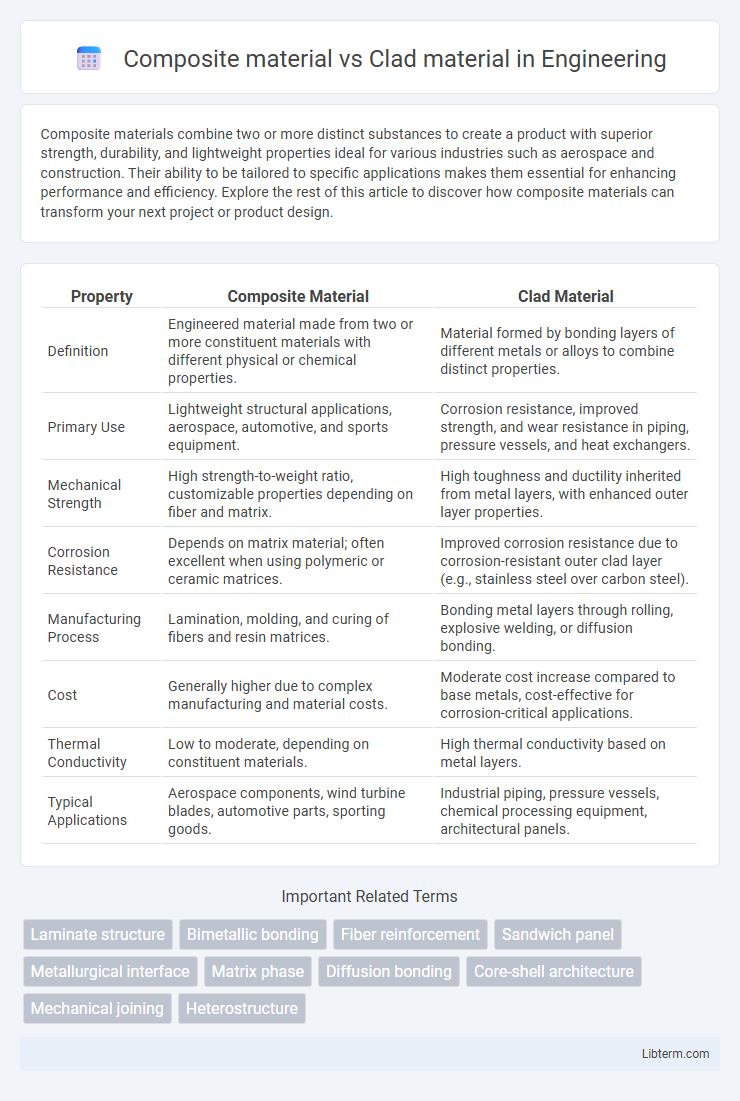

| Property | Composite Material | Clad Material |

|---|---|---|

| Definition | Engineered material made from two or more constituent materials with different physical or chemical properties. | Material formed by bonding layers of different metals or alloys to combine distinct properties. |

| Primary Use | Lightweight structural applications, aerospace, automotive, and sports equipment. | Corrosion resistance, improved strength, and wear resistance in piping, pressure vessels, and heat exchangers. |

| Mechanical Strength | High strength-to-weight ratio, customizable properties depending on fiber and matrix. | High toughness and ductility inherited from metal layers, with enhanced outer layer properties. |

| Corrosion Resistance | Depends on matrix material; often excellent when using polymeric or ceramic matrices. | Improved corrosion resistance due to corrosion-resistant outer clad layer (e.g., stainless steel over carbon steel). |

| Manufacturing Process | Lamination, molding, and curing of fibers and resin matrices. | Bonding metal layers through rolling, explosive welding, or diffusion bonding. |

| Cost | Generally higher due to complex manufacturing and material costs. | Moderate cost increase compared to base metals, cost-effective for corrosion-critical applications. |

| Thermal Conductivity | Low to moderate, depending on constituent materials. | High thermal conductivity based on metal layers. |

| Typical Applications | Aerospace components, wind turbine blades, automotive parts, sporting goods. | Industrial piping, pressure vessels, chemical processing equipment, architectural panels. |

Introduction to Composite and Clad Materials

Composite materials consist of two or more distinct constituents combined to achieve superior mechanical properties, such as enhanced strength, stiffness, and corrosion resistance, compared to individual components. Clad materials feature a core material bonded to a protective layer, typically metal, to improve surface properties like wear resistance and corrosion protection while maintaining core structural integrity. Both composites and clads are essential in aerospace, automotive, and construction industries for optimizing performance and durability.

Definition and Composition of Composite Materials

Composite materials consist of two or more distinct constituents, such as fibers and a matrix, combined to achieve superior mechanical properties like increased strength and stiffness. Common composites include fiberglass, carbon fiber-reinforced polymers, and concrete, where reinforcement materials are embedded in a bonding matrix to enhance durability and performance. Clad materials differ by layering different metals or alloys through bonding processes, maintaining individual metal properties rather than combining constituents at the microstructural level as composites do.

Definition and Structure of Clad Materials

Clad materials consist of multiple layers of different metals or alloys bonded together to combine distinct mechanical or chemical properties into a single structure. Their structure typically involves a core material laminated with outer layers, providing enhanced strength, corrosion resistance, or conductivity depending on the chosen metals. Unlike composites, which use a matrix and reinforcement phases, clad materials maintain metallic bonding throughout, ensuring uniform metallurgical integrity across the bonded layers.

Manufacturing Processes: Composite vs Clad

Composite materials are manufactured by combining two or more distinct materials, typically fibers embedded in a resin matrix, using processes such as lay-up, filament winding, or resin transfer molding that allow for tailored mechanical properties and complex shapes. Clad materials are produced through metallurgical bonding methods like roll bonding, explosion welding, or diffusion bonding, which fuse layers of different metals to create a single material with combined surface properties and enhanced corrosion resistance. The manufacturing of composites emphasizes layering and curing techniques, whereas cladding focuses on metallurgical bonding and uniform adhesion between metal layers.

Key Properties and Performance Comparison

Composite materials exhibit superior strength-to-weight ratios and enhanced corrosion resistance compared to clad materials, making them ideal for aerospace and automotive applications. Clad materials offer excellent surface protection with a strong, metallurgical bond between dissimilar metals, ensuring durability and improved wear resistance in environments requiring high structural integrity. Performance-wise, composites excel in fatigue resistance and thermal insulation, while clad materials provide enhanced electrical conductivity and impact resistance due to their layered structure.

Typical Applications in Industry

Composite materials are extensively used in aerospace, automotive, and marine industries due to their high strength-to-weight ratio and corrosion resistance, making them ideal for aircraft fuselages, automotive body panels, and boat hulls. Clad materials find typical applications in chemical processing, food and beverage, and power generation industries, where their layered structure provides superior corrosion resistance and thermal conductivity in piping, heat exchangers, and reactor vessels. The choice between composite and clad materials depends on specific industry requirements such as mechanical strength, environmental resistance, and thermal performance.

Advantages of Composite Materials

Composite materials offer superior strength-to-weight ratios compared to clad materials, making them ideal for aerospace and automotive applications where weight reduction is crucial. Their enhanced corrosion resistance and tailored mechanical properties provide greater durability and performance in harsh environments. Composite materials also allow for customizable fabrication, enabling engineers to optimize structures for specific load-bearing and thermal requirements.

Advantages of Clad Materials

Clad materials offer superior corrosion resistance by combining the properties of two or more metals, often pairing a corrosion-resistant surface with a strong, cost-effective core. They provide enhanced strength and durability while maintaining lightweight characteristics, making them ideal for aerospace and marine applications. Clad materials also exhibit improved weldability and thermal conductivity compared to composite materials, ensuring better performance in demanding industrial environments.

Cost Analysis and Economic Considerations

Composite materials often incur higher initial costs due to complex manufacturing processes and specialized raw materials, but their superior strength-to-weight ratios can lead to long-term savings in maintenance and operational efficiency. Clad materials, generally more cost-effective upfront, provide economical benefits through corrosion resistance and ease of fabrication, particularly in applications requiring surface protection without the need for full material replacement. Economic considerations must balance lifecycle costs, including durability, performance requirements, and environmental impact, to determine the most cost-efficient option for specific industrial applications.

Choosing the Right Material for Your Project

Composite materials combine two or more distinct substances to achieve enhanced strength, durability, and lightweight properties, ideal for applications requiring high performance and flexibility. Clad materials consist of a core metal bonded with a protective or decorative layer, providing corrosion resistance and aesthetic appeal without sacrificing structural integrity. Selecting the right material depends on project requirements such as mechanical strength, environmental exposure, weight constraints, and budget considerations.

Composite material Infographic

libterm.com

libterm.com