Hardness measures a material's resistance to deformation, scratching, or indentation, influencing its durability and wear resistance. Understanding hardness is crucial for selecting the right materials in applications ranging from construction to manufacturing. Discover how hardness impacts your projects by exploring the detailed insights in the rest of this article.

Table of Comparison

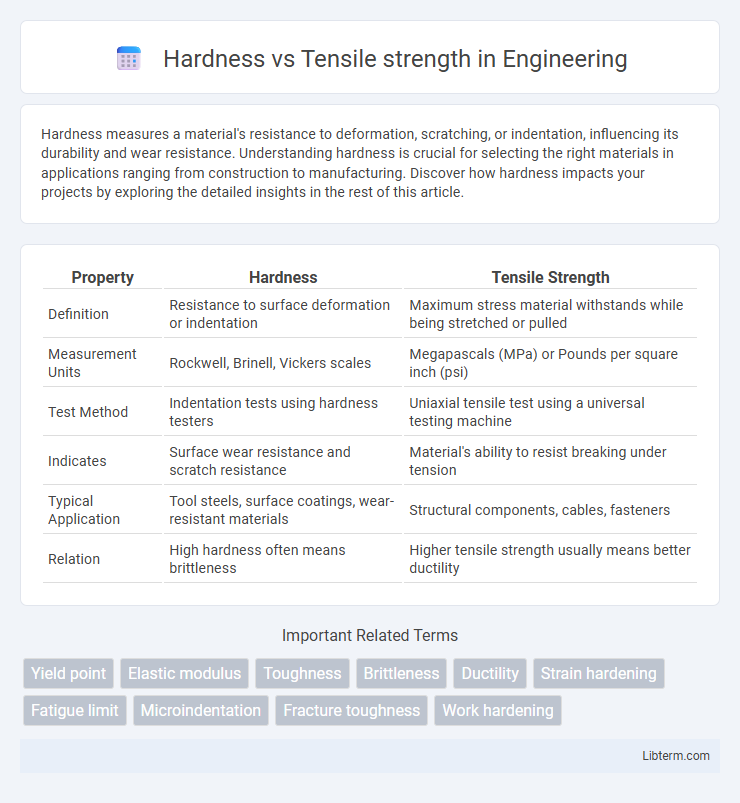

| Property | Hardness | Tensile Strength |

|---|---|---|

| Definition | Resistance to surface deformation or indentation | Maximum stress material withstands while being stretched or pulled |

| Measurement Units | Rockwell, Brinell, Vickers scales | Megapascals (MPa) or Pounds per square inch (psi) |

| Test Method | Indentation tests using hardness testers | Uniaxial tensile test using a universal testing machine |

| Indicates | Surface wear resistance and scratch resistance | Material's ability to resist breaking under tension |

| Typical Application | Tool steels, surface coatings, wear-resistant materials | Structural components, cables, fasteners |

| Relation | High hardness often means brittleness | Higher tensile strength usually means better ductility |

Introduction to Hardness and Tensile Strength

Hardness measures a material's resistance to indentation, scratching, or deformation, essential for assessing wear resistance in metals and alloys. Tensile strength quantifies the maximum stress a material can withstand while being stretched before failing, critical for structural performance and safety. Both properties provide complementary insights into material behavior under different mechanical stresses.

Defining Hardness: What Does It Measure?

Hardness measures a material's resistance to localized plastic deformation, typically assessed by indentation, scratching, or abrasion tests. It quantifies the ability of a surface to withstand penetration or wear, providing insights into the material's durability and scratch resistance. Unlike tensile strength, which measures the maximum stress a material can withstand while being stretched, hardness focuses on surface properties rather than bulk mechanical performance.

Understanding Tensile Strength: A Core Property

Tensile strength measures a material's resistance to breaking under tension, reflecting its ability to withstand pulling forces without failure. This core mechanical property is critical for designing structures and components that require durability and safety under load. Unlike hardness, which indicates surface resistance to indentation or scratching, tensile strength provides insight into the material's overall structural integrity and performance under stress.

Key Differences Between Hardness and Tensile Strength

Hardness measures a material's resistance to surface indentation or scratching, while tensile strength quantifies the maximum stress a material can withstand when stretched or pulled before breaking. Hardness tests, such as Mohs, Brinell, or Rockwell, evaluate surface durability, whereas tensile strength is determined through stress-strain analysis during tensile testing. The key difference lies in hardness reflecting surface resistance and tensile strength indicating overall structural capacity under tension.

Methods for Measuring Hardness

Hardness measurement methods include the Brinell, Rockwell, and Vickers tests, each utilizing indentation techniques to determine a material's resistance to deformation. The Brinell test uses a steel or carbide ball indenter under a specific load, ideal for coarse materials, while the Rockwell test measures the depth of penetration with various indenter types for faster results. Vickers hardness testing employs a diamond pyramid indenter under a controlled load, providing precise measurements for thin materials or coatings, distinct from tensile strength tests that measure resistance to elongation and fracture.

Techniques for Testing Tensile Strength

Tensile strength is commonly measured using techniques such as the universal testing machine (UTM), which applies a controlled tensile load to a specimen until failure, recording stress and strain data to determine ultimate tensile strength (UTS) and yield strength. Other methods include the use of extensometers and strain gauges to accurately capture elongation and deformation during tensile testing. Standardized procedures like ASTM E8/E8M ensure consistent sample preparation and testing protocols for reliable tensile strength measurement across different materials.

Material Examples: Hardness vs Tensile Strength

Tool steels such as A2 and D2 exhibit high hardness values, typically ranging from 55 to 65 HRC, while their tensile strength falls between 800 and 1200 MPa, making them ideal for wear-resistant applications. Aluminum alloys like 6061-T6 show moderate hardness around 95 HB with tensile strengths near 310 MPa, balancing machinability and strength for structural components. In contrast, stainless steels such as 304 and 316 combine hardness values of approximately 80-100 HB with tensile strengths of 520 to 750 MPa, offering corrosion resistance alongside mechanical durability.

Industrial Applications: Choosing the Right Property

Hardness and tensile strength are critical mechanical properties influencing material selection in industrial applications, with hardness determining resistance to surface deformation and wear, while tensile strength indicates the maximum stress a material can withstand before failure. Industries such as automotive manufacturing prioritize high tensile strength for structural components to ensure durability and safety, whereas tooling and machining sectors emphasize hardness to extend tool life and maintain precision. Optimizing product performance and lifespan requires balancing these properties based on operational demands, material compatibility, and cost-effectiveness.

Factors Influencing Hardness and Tensile Strength

Hardness and tensile strength are influenced by material composition, heat treatment, and microstructure variations. Alloying elements such as carbon in steel enhance hardness by forming carbides, while grain size refinement improves tensile strength through the Hall-Petch effect. Processing methods like quenching and tempering alter dislocation density, directly impacting both hardness and tensile strength.

Conclusion: Interpreting Hardness and Tensile Strength in Materials

Hardness and tensile strength provide complementary insights into a material's performance under different stress conditions, with hardness measuring resistance to deformation and tensile strength assessing the maximum load a material can withstand before failure. Interpreting these properties together allows engineers to select materials optimized for specific applications, balancing surface durability with structural integrity. Understanding the relationship between hardness and tensile strength is crucial for predicting wear resistance, fracture behavior, and overall material reliability.

Hardness Infographic

libterm.com

libterm.com