Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) are essential for industrial automation, offering precise control over manufacturing processes and improving operational efficiency. PLCs excel in discrete control applications requiring fast, reliable responses, while DCS is designed for complex processes with multiple control loops and integrated system management. Explore the article to understand how choosing between PLC and DCS can enhance your automation strategy.

Table of Comparison

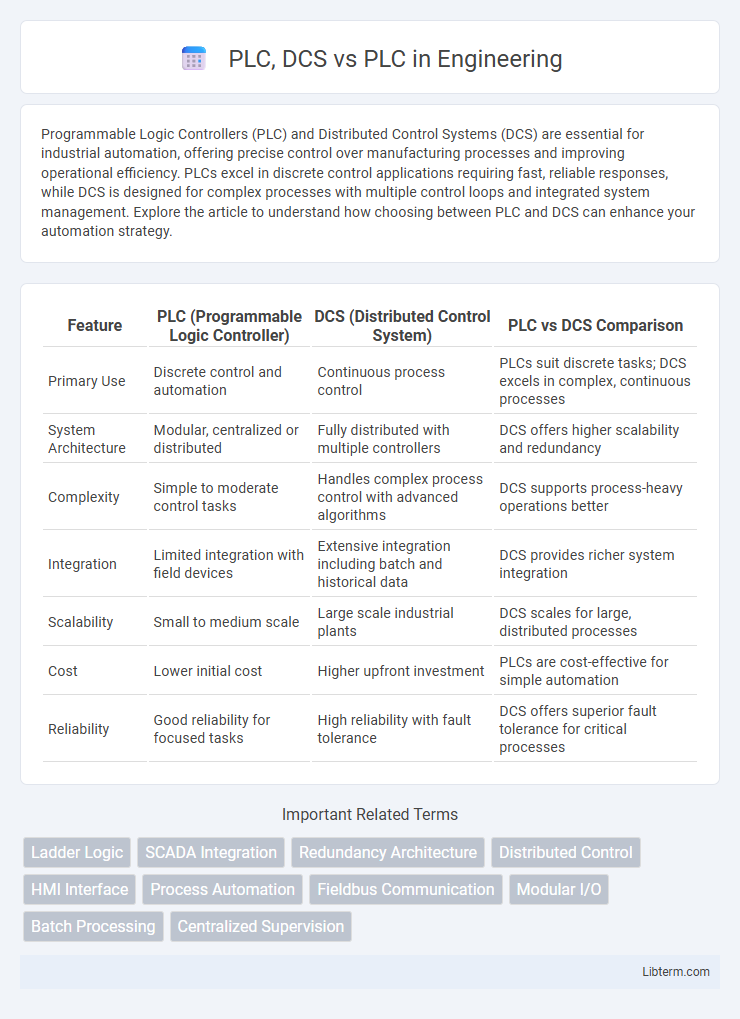

| Feature | PLC (Programmable Logic Controller) | DCS (Distributed Control System) | PLC vs DCS Comparison |

|---|---|---|---|

| Primary Use | Discrete control and automation | Continuous process control | PLCs suit discrete tasks; DCS excels in complex, continuous processes |

| System Architecture | Modular, centralized or distributed | Fully distributed with multiple controllers | DCS offers higher scalability and redundancy |

| Complexity | Simple to moderate control tasks | Handles complex process control with advanced algorithms | DCS supports process-heavy operations better |

| Integration | Limited integration with field devices | Extensive integration including batch and historical data | DCS provides richer system integration |

| Scalability | Small to medium scale | Large scale industrial plants | DCS scales for large, distributed processes |

| Cost | Lower initial cost | Higher upfront investment | PLCs are cost-effective for simple automation |

| Reliability | Good reliability for focused tasks | High reliability with fault tolerance | DCS offers superior fault tolerance for critical processes |

Understanding Programmable Logic Controllers (PLC)

Programmable Logic Controllers (PLCs) are industrial digital computers designed for real-time control of manufacturing processes, automating machinery with high reliability and flexibility. Distributed Control Systems (DCS) differ by providing centralized control with integrated data management, ideal for complex, continuous processes across large plants. PLCs excel in discrete and modular automation tasks, while DCS are optimized for process industries requiring scalable, networked control solutions.

Key Functions and Applications of PLCs

PLCs (Programmable Logic Controllers) excel in real-time control of discrete processes with key functions including input signal processing, logic execution, and output control, primarily used in manufacturing automation, machinery control, and packaging industries. Unlike DCS (Distributed Control Systems), which optimize continuous process control and data acquisition in large-scale operations like chemical plants and oil refineries, PLCs provide high-speed, precise control for tasks requiring immediate operational response. Their modular design, ease of programming, and robust performance make PLCs ideal for repetitive control applications, standalone machines, and smaller system automation.

What is a Distributed Control System (DCS)?

A Distributed Control System (DCS) is an automated control system where control elements are distributed throughout the system rather than centralized in a single location, enabling high reliability and flexibility for managing complex industrial processes. Unlike Programmable Logic Controllers (PLCs), which are primarily designed for discrete control tasks, DCS integrates multiple controllers to provide comprehensive process control and monitoring in industries such as chemical plants, power generation, and oil refining. DCS architecture allows real-time data acquisition, advanced process control, and fault tolerance through networked controllers and operator stations.

Core Features of DCS Architecture

DCS architecture centers on decentralized control with integrated controllers, operator stations, and engineering workstations designed for continuous processes requiring complex algorithms and detailed diagnostics. Unlike PLCs mainly used for discrete control tasks, DCS offers robust scalability, real-time data handling, and redundancy to ensure high reliability and fault tolerance in large-scale industrial environments. Core DCS features include distributed intelligence, hierarchical control layers, seamless integration with field devices, and advanced communication protocols supporting comprehensive process automation and optimization.

PLC vs DCS: Structural Differences

PLC (Programmable Logic Controller) systems are designed for discrete control tasks with modular, compact hardware facilitating fast, real-time processing and high reliability in automation. DCS (Distributed Control Systems) feature a hierarchical, distributed architecture optimized for continuous process control, integrating multiple controllers spread across plant areas with centralized monitoring. The key structural difference lies in PLC's centralized, processor-based modules versus DCS's networked, distributed control nodes, enabling scalability for large industrial processes.

Performance Comparison: PLC and DCS

PLC systems excel in fast, discrete control applications with high-speed processing capabilities and modular scalability, making them ideal for repetitive, real-time tasks. DCS platforms offer superior performance in complex, continuous process control with advanced data handling, integrated control strategies, and enhanced system redundancy for high reliability. Performance comparison highlights PLC's strength in speed and adaptability, while DCS provides robustness, centralized monitoring, and optimized control for large-scale industrial processes.

Scalability in PLC Versus DCS Systems

PLC systems offer modular scalability, allowing easy integration of additional I/O modules to accommodate expanding automation needs in discrete control applications. DCS systems provide superior scalability for complex and large-scale processes by supporting distributed control with multiple controllers and extensive networking capabilities. The inherent architecture of DCS enables seamless system expansion and advanced process management, making it ideal for continuous or batch process industries requiring high scalability and reliability.

Cost Analysis: PLC vs DCS Investment

PLC systems typically offer lower initial investment costs compared to DCS due to their modular design and easier scalability. DCS solutions, while more expensive upfront, provide integrated control with advanced process management features that may reduce long-term operational expenses. Cost analysis between PLC and DCS investments should consider project size, complexity, and maintenance requirements to determine the most economically viable option.

Industry Applications: Choosing Between PLC and DCS

PLCs excel in discrete manufacturing environments requiring fast, flexible control and modular scalability, commonly used in automotive, packaging, and material handling industries. DCS systems are preferred for continuous or batch processes demanding high reliability and integrated control, such as in chemical plants, oil refineries, and power generation facilities. Selecting PLC versus DCS depends on process complexity, control architecture needs, and integration requirements within specific industrial applications.

Future Trends in PLC and DCS Technologies

PLC and DCS technologies are evolving with advancements in Industrial Internet of Things (IIoT), edge computing, and artificial intelligence integration, driving smarter automation and predictive maintenance. Future trends emphasize seamless interoperability between PLCs and DCS for enhanced process control, real-time data analytics, and improved cybersecurity measures. Increased adoption of wireless communication protocols and cloud-based monitoring enhances scalability and remote accessibility in complex industrial environments.

PLC, DCS Infographic

libterm.com

libterm.com