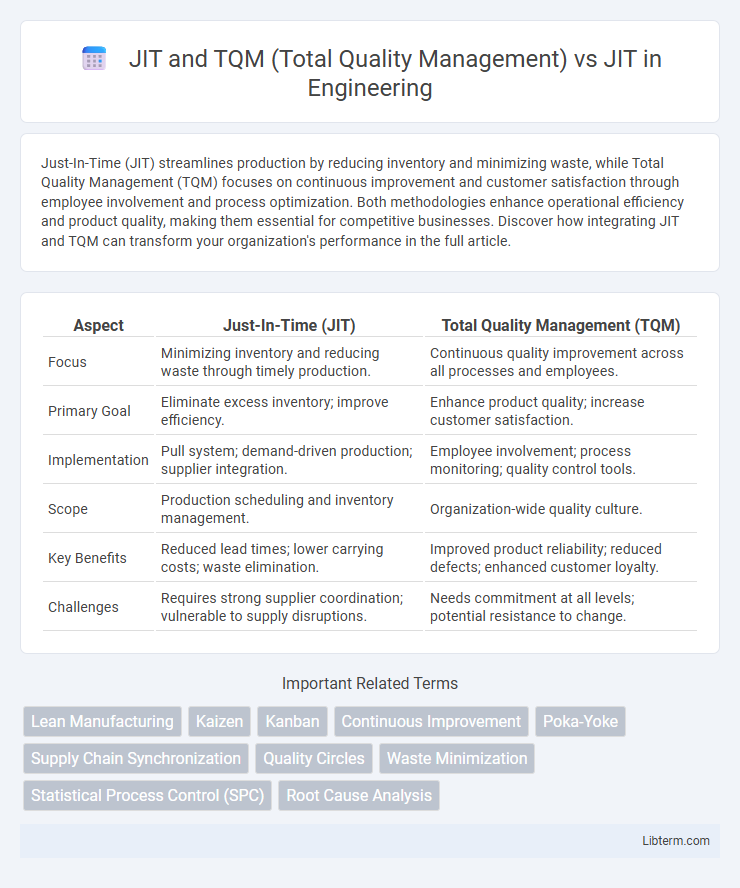

Just-In-Time (JIT) streamlines production by reducing inventory and minimizing waste, while Total Quality Management (TQM) focuses on continuous improvement and customer satisfaction through employee involvement and process optimization. Both methodologies enhance operational efficiency and product quality, making them essential for competitive businesses. Discover how integrating JIT and TQM can transform your organization's performance in the full article.

Table of Comparison

| Aspect | Just-In-Time (JIT) | Total Quality Management (TQM) |

|---|---|---|

| Focus | Minimizing inventory and reducing waste through timely production. | Continuous quality improvement across all processes and employees. |

| Primary Goal | Eliminate excess inventory; improve efficiency. | Enhance product quality; increase customer satisfaction. |

| Implementation | Pull system; demand-driven production; supplier integration. | Employee involvement; process monitoring; quality control tools. |

| Scope | Production scheduling and inventory management. | Organization-wide quality culture. |

| Key Benefits | Reduced lead times; lower carrying costs; waste elimination. | Improved product reliability; reduced defects; enhanced customer loyalty. |

| Challenges | Requires strong supplier coordination; vulnerable to supply disruptions. | Needs commitment at all levels; potential resistance to change. |

Overview of Just-In-Time (JIT) Methodology

Just-In-Time (JIT) methodology streamlines inventory management by minimizing stock levels and reducing waste through precise production scheduling aligned with demand. Unlike Total Quality Management (TQM), which emphasizes continuous improvement and defect reduction across all organizational processes, JIT focuses specifically on enhancing efficiency in supply chain and manufacturing operations. Implementing JIT requires robust supplier relationships and real-time data monitoring to ensure materials and components arrive exactly when needed, boosting operational agility and lowering carrying costs.

Foundations of Total Quality Management (TQM)

Total Quality Management (TQM) is founded on continuous improvement, customer focus, and employee involvement, aiming for long-term quality enhancement across all organizational processes. JIT (Just-In-Time) emphasizes inventory reduction and waste minimization by producing only what is needed when needed, which supports TQM principles by enhancing process efficiency and product quality. The synergy between JIT and TQM lies in TQM's foundation of quality culture and systematic problem-solving, which ensures JIT's timely production achieves defect-free output and customer satisfaction.

Core Principles Shared by JIT and TQM

Just-In-Time (JIT) and Total Quality Management (TQM) share core principles centered on continuous improvement, waste reduction, and customer satisfaction. Both philosophies emphasize employee involvement and process standardization to enhance efficiency and product quality. Integrating JIT's focus on inventory minimization with TQM's commitment to defect prevention creates a synergistic approach that drives operational excellence.

Key Differences: JIT vs TQM

JIT (Just-In-Time) focuses on inventory reduction and streamlining production processes to minimize waste and improve efficiency by receiving materials only as needed. TQM (Total Quality Management) emphasizes continuous quality improvement across all organizational processes, involving all employees to enhance product quality and customer satisfaction. While JIT aims primarily at operational efficiency through inventory control, TQM targets a holistic approach to quality enhancement throughout the enterprise.

JIT Implementation Strategies

Just-In-Time (JIT) implementation strategies emphasize reducing inventory levels, streamlining production processes, and fostering strong supplier relationships to achieve efficient workflow and minimize waste. Total Quality Management (TQM) complements JIT by focusing on continuous improvement, employee involvement, and quality control to ensure defects are minimized throughout the production stages. Combining JIT with TQM leads to enhanced operational efficiency, reduced costs, and higher customer satisfaction by aligning quality processes with lean inventory management.

TQM Implementation Best Practices

TQM implementation best practices emphasize continuous improvement, employee involvement, and customer-focused quality management to enhance organizational performance. Unlike JIT, which primarily targets inventory reduction and waste elimination through precise production scheduling, TQM integrates cross-functional teams and systematic problem-solving to drive long-term quality culture. Effective TQM deployment relies on leadership commitment, rigorous training, and data-driven decision-making to sustain improvements aligned with business objectives.

Synergy Between JIT and TQM in Manufacturing

JIT (Just-In-Time) and TQM (Total Quality Management) create a powerful synergy in manufacturing by streamlining production processes and enhancing product quality concurrently. JIT reduces inventory waste and response time, while TQM emphasizes continuous improvement and defect reduction, leading to optimized operational efficiency and higher customer satisfaction. Integrating JIT with TQM results in a cohesive system that fosters a culture of quality and lean manufacturing, driving both cost savings and competitive advantage.

Benefits of Combining JIT and TQM Approaches

Combining Just-In-Time (JIT) and Total Quality Management (TQM) creates a powerful synergy that enhances operational efficiency and product quality by minimizing waste and promoting continuous improvement. This integration leads to reduced inventory costs, faster production cycles, and improved customer satisfaction through consistent defect-free outputs. The joint application ensures streamlined processes and fosters a culture of quality awareness among employees, driving sustained competitive advantage.

Challenges in Integrating JIT with TQM

Integrating Just-In-Time (JIT) with Total Quality Management (TQM) faces challenges such as aligning continuous improvement processes with precise inventory control, requiring synchronized employee training and cultural shifts. Resistance to change can hinder the adoption of TQM's quality-focused mindset alongside JIT's emphasis on waste reduction and timely production. Ensuring consistent supplier quality and managing variability in production flow compound difficulties in achieving seamless integration between JIT and TQM frameworks.

Future Trends: JIT and TQM in Modern Industries

Future trends in JIT and Total Quality Management (TQM) emphasize the integration of advanced technologies such as AI and IoT to enhance real-time data analytics and process automation. Modern industries increasingly adopt hybrid models combining JIT's inventory efficiency with TQM's focus on continuous quality improvement to drive sustainability and customer satisfaction. The convergence of JIT and TQM fosters agile supply chains and adaptive quality management systems, positioning companies for competitive advantage in dynamic global markets.

JIT and TQM (Total Quality Management) Infographic

libterm.com

libterm.com