Stepped shafts are mechanical components featuring varying diameters along their length, designed to accommodate different bearing sizes or gears, enhancing load distribution and assembly flexibility. Their precise machining ensures improved torque transmission and alignment in complex machinery. Explore this article to understand how a stepped shaft can optimize your mechanical design and performance.

Table of Comparison

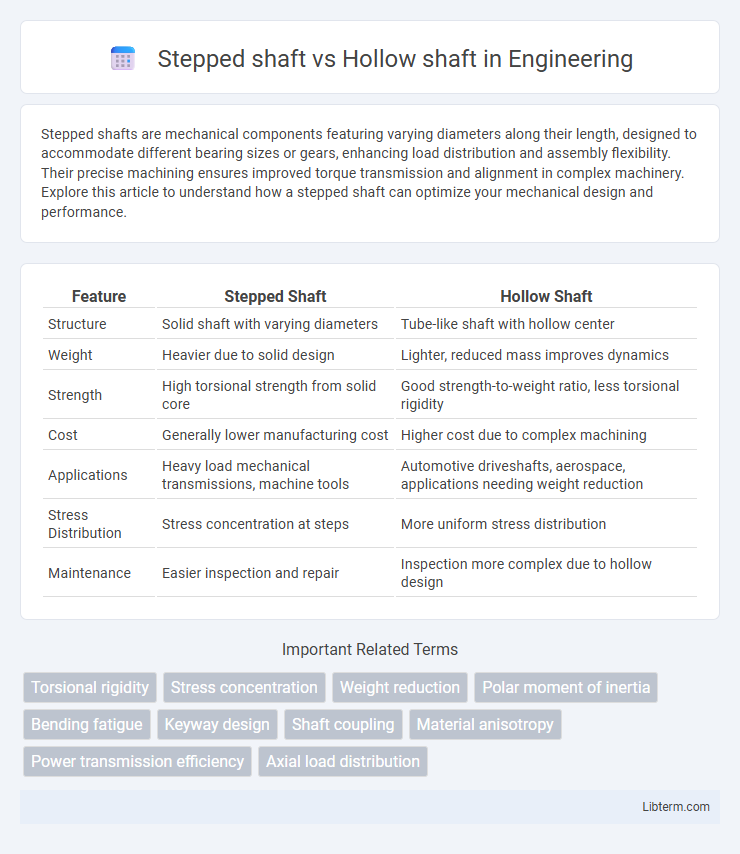

| Feature | Stepped Shaft | Hollow Shaft |

|---|---|---|

| Structure | Solid shaft with varying diameters | Tube-like shaft with hollow center |

| Weight | Heavier due to solid design | Lighter, reduced mass improves dynamics |

| Strength | High torsional strength from solid core | Good strength-to-weight ratio, less torsional rigidity |

| Cost | Generally lower manufacturing cost | Higher cost due to complex machining |

| Applications | Heavy load mechanical transmissions, machine tools | Automotive driveshafts, aerospace, applications needing weight reduction |

| Stress Distribution | Stress concentration at steps | More uniform stress distribution |

| Maintenance | Easier inspection and repair | Inspection more complex due to hollow design |

Introduction to Stepped Shafts and Hollow Shafts

Stepped shafts feature distinct diameter changes along their length, allowing for different components like gears or bearings to be mounted securely while optimizing strength and weight. Hollow shafts reduce overall mass and inertia by incorporating a central cavity, enhancing torque transmission efficiency in applications such as automotive drive shafts and industrial machinery. Both stepped and hollow shafts are integral in mechanical design, balancing structural requirements with performance needs across various engineering systems.

Mechanical Design Differences

Stepped shafts feature varying diameters along their length, providing enhanced strength and stress distribution at critical points, whereas hollow shafts have a uniform outer diameter with a hollow center, reducing weight while maintaining rigidity. The mechanical design of stepped shafts allows for better accommodation of bearings and gears due to diameter transitions, while hollow shafts optimize material usage for torsional stiffness and bending resistance. Stepped shafts typically handle higher bending loads, whereas hollow shafts excel in applications requiring weight reduction without compromising structural integrity.

Material Selection Considerations

Material selection for stepped shafts often prioritizes high-strength alloys such as carbon steel or alloy steel to withstand varied stress concentrations at diameter changes, while hollow shafts typically use materials with high strength-to-weight ratios like aluminum or composite alloys to reduce weight without compromising rigidity. Stepped shafts require materials with excellent fatigue resistance and machinability due to complex geometry, whereas hollow shafts demand materials with superior torsional strength and corrosion resistance for applications involving torque transmission and exposure to harsh environments. Cost-efficiency in manufacturing and maintenance also influences material choice, with stepped shafts favoring easily weldable and heat-treatable steels, and hollow shafts benefiting from lightweight, high-performance materials to optimize dynamic performance.

Strength and Load-Bearing Capabilities

Stepped shafts exhibit enhanced strength and superior load-bearing capabilities due to their varying diameters, which allow for optimized stress distribution and resistance to bending moments. Hollow shafts provide significant weight reduction while maintaining comparable strength, but their load-bearing capacity is generally lower than that of stepped shafts due to the reduced cross-sectional area. Material selection and application-specific load requirements critically affect the performance differences between stepped and hollow shafts in mechanical systems.

Weight and Material Efficiency

Stepped shafts offer improved material efficiency by reducing unnecessary mass in less stressed sections, resulting in a lighter component compared to uniform shafts. Hollow shafts further enhance weight savings by removing central material, maintaining strength while significantly lowering overall weight. Both designs optimize mechanical performance and material use, with hollow shafts typically providing superior weight reduction and stepped shafts balancing strength and cost efficiency.

Manufacturing Processes and Costs

Stepped shafts involve multiple diameter changes produced through machining processes like turning and grinding, leading to higher labor and tooling costs due to complex operations. Hollow shafts are typically manufactured using tube forming, extrusion, or machining from seamless tubes, reducing material usage and machining time, which lowers production costs. Manufacturing hollow shafts requires precise control to maintain strength while optimizing weight, often resulting in cost benefits for applications demanding lighter components.

Applications in Industry

Stepped shafts are widely used in machinery requiring varying diameters for mounting components such as gears, bearings, and pulleys, offering precise load distribution and alignment in automotive and manufacturing industries. Hollow shafts find extensive application in aerospace and robotics due to their lightweight structure combined with high torque transmission and flexibility for cabling or fluid passage. Both shaft types optimize mechanical performance in industrial automation, with stepped shafts enhancing strength at critical points and hollow shafts reducing overall system weight.

Performance in Dynamic Conditions

Stepped shafts offer enhanced torsional rigidity and fatigue resistance due to their varying diameters, making them suitable for dynamic conditions with fluctuating loads. Hollow shafts reduce weight and rotational inertia, improving acceleration and vibration damping but may exhibit lower bending strength under high-stress dynamic operations. Selecting between stepped and hollow shafts depends on balancing stiffness, weight, and fatigue performance for specific dynamic load profiles.

Maintenance and Durability Factors

Stepped shafts typically require more frequent maintenance due to stress concentration at the step transitions, which can lead to fatigue and potential failure points. Hollow shafts offer improved durability by reducing weight and evenly distributing stress, resulting in lower wear and extended service life. Maintenance of hollow shafts often involves less frequent inspections and simpler repairs because of their enhanced structural integrity and resistance to torsional stress.

Conclusion: Choosing the Right Shaft Type

Choosing the right shaft type depends on application requirements such as load capacity, weight, and manufacturing complexity. Stepped shafts offer higher strength at critical points due to variable diameters, making them ideal for heavy-duty applications requiring precise load distribution. Hollow shafts provide significant weight reduction and improved torsional rigidity, benefiting high-speed or lightweight machinery where reduced inertia is crucial.

Stepped shaft Infographic

libterm.com

libterm.com