Gear drives efficiently transmit power between rotating shafts, ensuring precise motion and torque control in various mechanical systems. Their design minimizes slippage and maximizes durability, making them essential for applications ranging from automotive to industrial machinery. Discover how gear drives can enhance your system's performance by exploring the detailed insights in this article.

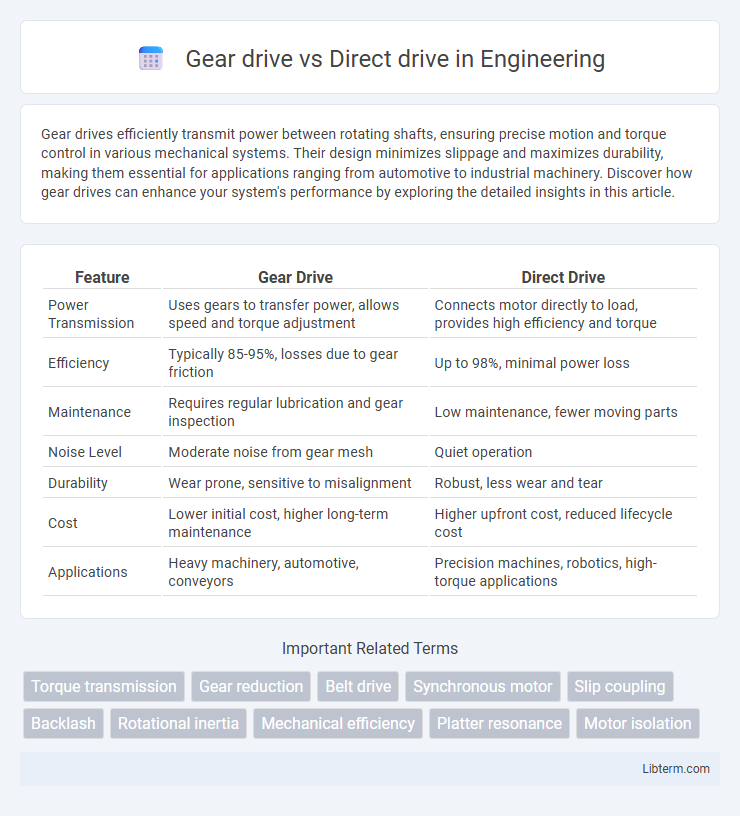

Table of Comparison

| Feature | Gear Drive | Direct Drive |

|---|---|---|

| Power Transmission | Uses gears to transfer power, allows speed and torque adjustment | Connects motor directly to load, provides high efficiency and torque |

| Efficiency | Typically 85-95%, losses due to gear friction | Up to 98%, minimal power loss |

| Maintenance | Requires regular lubrication and gear inspection | Low maintenance, fewer moving parts |

| Noise Level | Moderate noise from gear mesh | Quiet operation |

| Durability | Wear prone, sensitive to misalignment | Robust, less wear and tear |

| Cost | Lower initial cost, higher long-term maintenance | Higher upfront cost, reduced lifecycle cost |

| Applications | Heavy machinery, automotive, conveyors | Precision machines, robotics, high-torque applications |

Introduction to Gear Drive and Direct Drive

Gear drive systems utilize interlocking gears to transmit torque and rotational speed between shafts, offering precise control and high torque multiplication, commonly used in automotive transmissions and industrial machinery. Direct drive systems eliminate intermediary gears by connecting the motor directly to the load, reducing mechanical losses and maintenance while providing higher efficiency and smoother operation, often found in electric vehicles and turntables. Understanding the fundamental differences in design and application between gear drive and direct drive helps optimize performance, durability, and energy consumption across various mechanical and electromechanical systems.

How Gear Drive Systems Work

Gear drive systems operate by transmitting torque through a series of interlocking gears, which convert input motion into desired output speed or force. Each gear in the system meshes with another, allowing rotational energy to be transferred efficiently while adjusting torque and rotational speed based on gear ratios. This mechanical advantage enables precise control and power multiplication in applications ranging from automotive transmissions to industrial machinery.

How Direct Drive Systems Work

Direct drive systems function by coupling the motor directly to the load, eliminating the need for intermediate gears and reducing mechanical losses. They use high-torque, low-speed motors that enable precise control and smooth operation, enhancing efficiency and response time. This design minimizes maintenance requirements and improves reliability by reducing wear caused by gear friction and alignment issues.

Key Differences Between Gear Drive and Direct Drive

Gear drive systems use interlocking gears to transmit torque and adjust speed, offering precise control and high torque multiplication suitable for heavy-duty applications. Direct drive systems eliminate gears by connecting the motor directly to the load, providing higher efficiency, reduced maintenance, and quieter operation ideal for applications requiring smooth and rapid response. The primary differences lie in mechanical complexity, energy efficiency, and maintenance demands, with gear drives favored for torque and load adaptation, while direct drives excel in simplicity and performance consistency.

Efficiency Comparison: Gear Drive vs Direct Drive

Gear drives typically experience efficiency losses ranging from 5% to 15% due to friction and mechanical complexity, while direct drives achieve higher efficiency levels, often exceeding 95%, by eliminating intermediary components. The reduced mechanical resistance in direct drive systems results in lower energy consumption and improved torque transmission. Consequently, direct drives are favored in applications demanding high precision and energy efficiency.

Maintenance Requirements and Costs

Gear drive systems typically require regular lubrication, periodic inspections, and replacement of worn gears, resulting in higher maintenance costs over time. Direct drive systems have fewer moving parts, significantly reducing maintenance needs and associated expenses. The long-term operational cost benefits of direct drive outweigh initial investment, especially in applications demanding reliability and minimal downtime.

Performance and Noise Levels

Gear drive systems typically offer higher torque and precise control due to mechanical advantage but generate more noise from gear meshing and vibrations. Direct drive motors deliver smoother performance with minimal mechanical losses, resulting in quieter operation and faster response times. Noise level comparisons show direct drives operating significantly quieter, often making them preferable in environments sensitive to acoustic disturbances.

Applications Best Suited for Gear Drive

Gear drives are best suited for applications requiring high torque output and precise speed control, such as industrial machinery, conveyor systems, and automotive transmissions. They excel in heavy-duty environments where durability and power transmission efficiency are critical. Common uses include metalworking equipment, agricultural machinery, and robotics, where reliable gear engagement ensures consistent performance.

Applications Best Suited for Direct Drive

Direct drive systems excel in applications requiring high precision, low maintenance, and quiet operation, such as robotics, CNC machines, and high-speed turntables. These drives eliminate gears, resulting in reduced backlash and improved torque transmission, ideal for servo motors and precision positioning tasks. Industries like aerospace and semiconductor manufacturing benefit from direct drive's accuracy and reliability in critical motion control applications.

Choosing the Right Drive System for Your Needs

Gear drives provide higher torque and precise speed control, making them ideal for heavy-duty applications requiring durability and load handling. Direct drives offer greater energy efficiency, lower maintenance, and quieter operation, suitable for systems prioritizing simplicity and smooth performance. Selecting the right drive system depends on factors like load requirements, maintenance capacity, efficiency needs, and operational noise levels.

Gear drive Infographic

libterm.com

libterm.com