Flume is a powerful data collection service designed to efficiently ingest large volumes of log data from various sources into centralized storage systems. It supports scalability, reliability, and real-time data streaming, making it essential for big data processing architectures. Explore the rest of the article to learn how Flume can optimize your data pipeline and improve analytics performance.

Table of Comparison

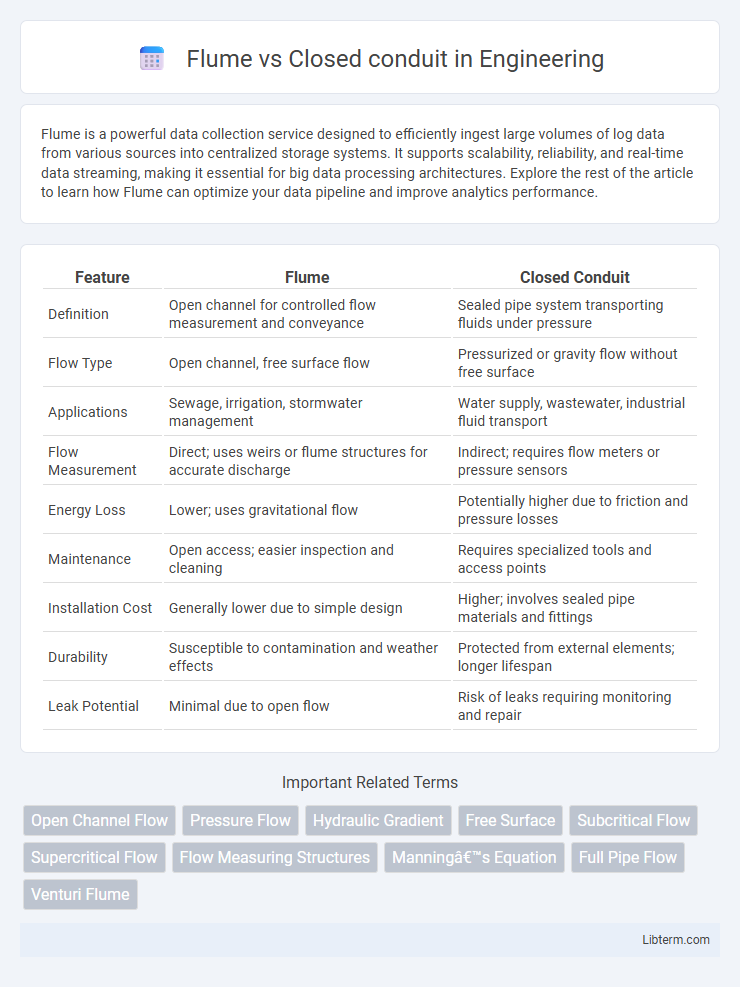

| Feature | Flume | Closed Conduit |

|---|---|---|

| Definition | Open channel for controlled flow measurement and conveyance | Sealed pipe system transporting fluids under pressure |

| Flow Type | Open channel, free surface flow | Pressurized or gravity flow without free surface |

| Applications | Sewage, irrigation, stormwater management | Water supply, wastewater, industrial fluid transport |

| Flow Measurement | Direct; uses weirs or flume structures for accurate discharge | Indirect; requires flow meters or pressure sensors |

| Energy Loss | Lower; uses gravitational flow | Potentially higher due to friction and pressure losses |

| Maintenance | Open access; easier inspection and cleaning | Requires specialized tools and access points |

| Installation Cost | Generally lower due to simple design | Higher; involves sealed pipe materials and fittings |

| Durability | Susceptible to contamination and weather effects | Protected from external elements; longer lifespan |

| Leak Potential | Minimal due to open flow | Risk of leaks requiring monitoring and repair |

Introduction to Flumes and Closed Conduits

Flumes are open channels designed to measure flow rates by constricting water flow and creating a controlled cross-section, enabling accurate flow measurement in natural and artificial waterways. Closed conduits are enclosed pipes or tubes that transport fluids under pressure, often requiring flow meters like electromagnetic or ultrasonic devices for precise measurement. Understanding the hydraulic principles of flumes and the pressurized conditions in closed conduits is essential for selecting appropriate flow measurement solutions.

Definitions: Flume vs Closed Conduit

Flume refers to an open channel designed to measure flow rates by allowing water or fluids to pass freely over a weir or through a constricted section, enabling accurate measurement of velocity and volume. Closed conduit describes a fully enclosed pipe or tube system that transports liquids or gases without exposure to the atmosphere, typically used for pressurized flow applications. Understanding the distinction between open flow in flumes and pressurized flow in closed conduits is essential for selecting the appropriate hydraulic structure in water management systems.

Key Differences in Design and Structure

Flumes are open-channel flow measuring structures designed with a specific geometric shape that accelerates water flow, allowing accurate discharge measurement without requiring a full channel cross-section. Closed conduits are fully enclosed pipes or tunnels that convey flow under pressure, with flow measurement relying on devices like flow meters or pressure sensors rather than open-channel geometry. The structural design of flumes emphasizes a controlled, open flow environment, while closed conduits focus on maintaining pressurized flow within sealed, rigid boundaries.

Applications of Flumes in Water Management

Flumes are widely used in water management for accurately measuring flow in open channels such as irrigation canals, wastewater treatment plants, and natural streams. Their design enables reliable flow rate data collection even in non-ideal channel conditions, enhancing water resource allocation and flood monitoring. Closed conduits, while suitable for pressurized pipe systems, are less adaptable for open channel flow measurement compared to flumes, which offer versatile application in diverse environmental settings.

Uses of Closed Conduits in Fluid Transport

Closed conduits are essential in fluid transport systems for carrying liquids and gases under pressure, commonly used in pipelines, water supply networks, and sewage systems. These conduits provide efficient, leak-proof transport, minimizing contamination and ensuring controlled flow rates. Their design supports various industrial applications, including chemical processing, HVAC systems, and oil and gas pipelines, due to their durability and ability to handle high-pressure environments.

Flow Measurement: Accuracy in Flumes and Conduits

Flumes provide highly accurate flow measurement due to their defined cross-sectional shape and critical flow conditions, which enable precise calculations of discharge based on water depth. Closed conduits, often measured using devices like ultrasonic or electromagnetic flow meters, can achieve accurate readings but require careful calibration and flow profile considerations, especially under varying flow regimes. Flumes generally offer better consistency in flow measurement accuracy, particularly in open channel applications with fluctuating flow rates.

Installation and Maintenance Requirements

Flumes offer easier installation in open channels with minimal site disruption compared to closed conduits, which require extensive trenching and sealing for buried pipelines. Maintenance of flumes typically involves removing debris and routine inspections accessible from the surface, whereas closed conduits demand confined space entry and specialized equipment for cleaning and repairs. Choosing between flume and closed conduit systems depends heavily on site conditions, accessibility, and long-term operational management.

Cost Comparison: Flume vs Closed Conduit

Flumes generally have lower initial installation costs compared to closed conduits due to their simpler construction and less material requirement. Closed conduits, such as pipes, often involve higher costs related to excavation, pipe fabrication, and joint sealing, raising overall expenditure. Maintenance expenses for flumes tend to be lower, whereas closed conduits may incur additional costs for inspection and cleaning to prevent blockages.

Advantages and Limitations of Each System

Flume systems offer advantages such as easy installation, precise flow measurement in open channels, and minimal flow disturbance, making them ideal for low-flow or partially filled channels. However, they are limited by sensitivity to debris and require a free-flowing condition to maintain accuracy. Closed conduits provide reliable, full-pipe flow measurement with minimal site impact and are less affected by environmental conditions, but they often involve complex installation and maintenance, and can be susceptible to pressure variations and pipe wear.

Choosing the Right Solution for Your Project

Selecting between flume and closed conduit systems hinges on project-specific factors such as flow measurement accuracy, maintenance needs, and environmental conditions. Flumes provide precise open-channel flow measurement and are ideal for natural streams or wastewater, while closed conduits suit pressurized flows, minimizing leakage and contamination risks. Evaluating site constraints, budget, and flow characteristics ensures the optimal hydraulic structure for efficient fluid conveyance and control.

Flume Infographic

libterm.com

libterm.com