Torsion refers to the twisting of an object due to applied torque, commonly seen in mechanical shafts and structural beams. Understanding torsion is essential for ensuring the durability and safety of engineering designs by analyzing shear stresses and deformations. Explore the rest of this article to learn how torsion impacts material performance and how to calculate it effectively.

Table of Comparison

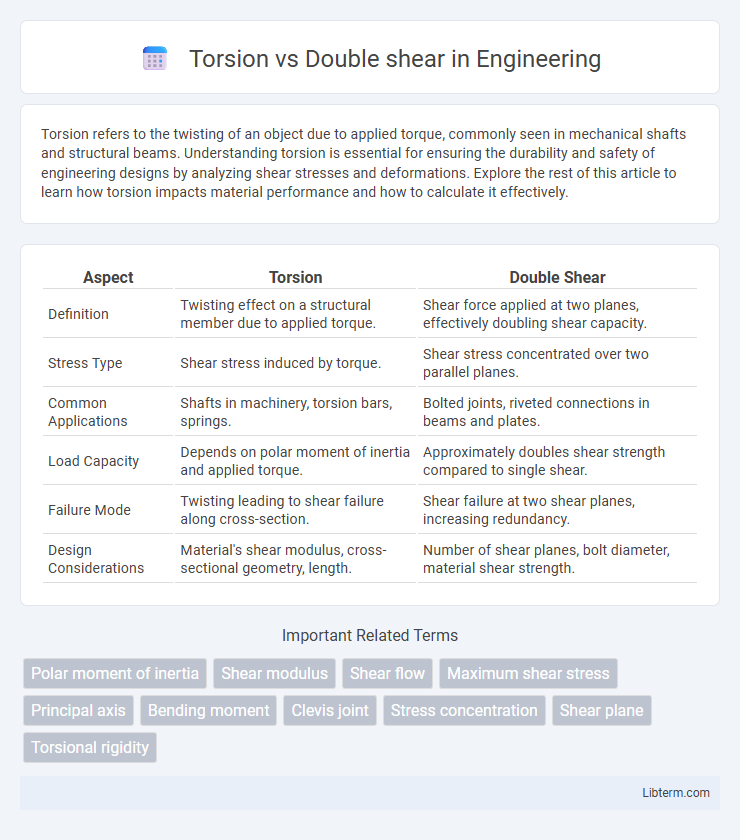

| Aspect | Torsion | Double Shear |

|---|---|---|

| Definition | Twisting effect on a structural member due to applied torque. | Shear force applied at two planes, effectively doubling shear capacity. |

| Stress Type | Shear stress induced by torque. | Shear stress concentrated over two parallel planes. |

| Common Applications | Shafts in machinery, torsion bars, springs. | Bolted joints, riveted connections in beams and plates. |

| Load Capacity | Depends on polar moment of inertia and applied torque. | Approximately doubles shear strength compared to single shear. |

| Failure Mode | Twisting leading to shear failure along cross-section. | Shear failure at two shear planes, increasing redundancy. |

| Design Considerations | Material's shear modulus, cross-sectional geometry, length. | Number of shear planes, bolt diameter, material shear strength. |

Introduction to Torsion and Double Shear

Torsion refers to the twisting of an object due to an applied torque, causing shear stress over the cross-sectional area perpendicular to the axis of rotation. Double shear occurs when a fastener or structural element is subjected to two distinct shear planes, effectively doubling the shear resistance compared to single shear. Understanding the differences between torsion and double shear is critical in mechanical design to ensure structural integrity and proper load distribution.

Fundamental Concepts Defined

Torsion involves twisting a structural element around its longitudinal axis, generating shear stress distributed over the cross section, and is quantified by torque and polar moment of inertia. Double shear refers to a loading condition where a fastener or material is subjected to shear forces across two planes simultaneously, effectively doubling the shear area compared to single shear. Understanding these fundamental concepts allows engineers to calculate stress distribution and design components for optimal strength under rotational and shear loads.

Mechanical Behavior Under Load

Torsion induces shear stress distributed over the cross-section, causing angular deformation primarily characterized by twisting around the longitudinal axis. Double shear subjects a material to two parallel forces acting in opposite directions, creating shear stress over two planes, effectively doubling the shear area and reducing stress concentration compared to single shear. The mechanical behavior under torsion involves shear strain energy accumulation and potential warping, while double shear promotes balanced load distribution and enhanced structural stability.

Stress Distribution Comparison

Torsion induces shear stresses distributed circumferentially along the cross-section, peaking at the outer fibers and diminishing toward the center, characterized by a linear variation in stress magnitude. Double shear involves two parallel shear planes where the load divides equally, resulting in uniform shear stress distribution across the shear area. Comparing stress distributions, torsion presents a non-uniform, radial gradient of shear stress, whereas double shear exhibits a consistent, evenly distributed shear stress across the interface.

Failure Modes in Torsion vs Double Shear

Failure modes in torsion primarily involve shear stress leading to twisting and potential fracture along the material's cross-section, often resulting in spiraling cracks due to the torque applied. In contrast, double shear failure occurs when the load causes two shear planes to simultaneously yield or fracture, effectively splitting the connecting material into three segments. Understanding these distinct failure mechanisms is critical for designing components subjected to twisting loads or shear forces to ensure structural integrity and safety.

Key Applications in Engineering

Torsion is critical in the design of shafts, springs, and drive components where rotational forces cause twisting stress, commonly found in automotive and aerospace engineering. Double shear is essential in structural engineering and mechanical fasteners, such as bolts and rivets, where two shear planes improve load distribution and enhance joint strength. Understanding the application of torsion and double shear allows engineers to optimize material use and ensure safety in high-stress environments.

Calculation Methods and Formulas

Torsion calculations involve determining the torque (T), polar moment of inertia (J), and shear stress (t) using the formula t = T*r/J, where r is the radius from the center to the point of interest. Double shear analysis requires calculating the shear force divided by twice the cross-sectional area (A), using t = F/(2A), to account for two shear planes. Both methods depend on accurately identifying the geometry and load conditions to ensure precise stress and strength evaluations.

Material Considerations and Selection

Material selection for torsion must prioritize high shear strength and torsional rigidity to withstand twisting stresses without permanent deformation. In double shear applications, materials need excellent tensile and shear strength to resist forces acting on two shear planes simultaneously, ensuring structural integrity. Alloy steel and high-strength composites are commonly favored for both cases due to their superior mechanical properties and fatigue resistance under cyclic loading.

Advantages and Limitations

Torsion provides uniform stress distribution along cylindrical shafts, making it ideal for transmitting rotational power in mechanical systems, but it may lead to complex stress states requiring careful material selection and design considerations. Double shear significantly increases the load-carrying capacity of fasteners or joints by distributing forces across two planes, reducing the risk of shear failure, yet it demands precise alignment and can increase manufacturing complexity. While torsion suits components like drive shafts, double shear excels in bolted or riveted connections, highlighting their specific advantages and constraints in engineering applications.

Summary and Engineering Implications

Torsion involves twisting a structural element about its longitudinal axis, generating shear stresses distributed over the cross-section, whereas double shear applies force across two distinct planes, effectively reducing the shear stress on the material. Engineers must evaluate torsional stresses to prevent warping or failure in shafts and beams subject to rotational loads, while double shear designs enhance load-bearing capacity by splitting forces, often utilized in bolted connections and riveted joints. Understanding these differences optimizes structural integrity and material efficiency in mechanical and civil engineering applications.

Torsion Infographic

libterm.com

libterm.com