K-truss is a graph theory concept used to identify cohesive subgraphs where each edge participates in at least k-2 triangles, revealing tightly connected communities within networks. This structure strengthens the analysis of social, biological, and communication networks by highlighting critical relationships and influential nodes. Explore the full article to understand how K-truss can enhance your network analysis techniques.

Table of Comparison

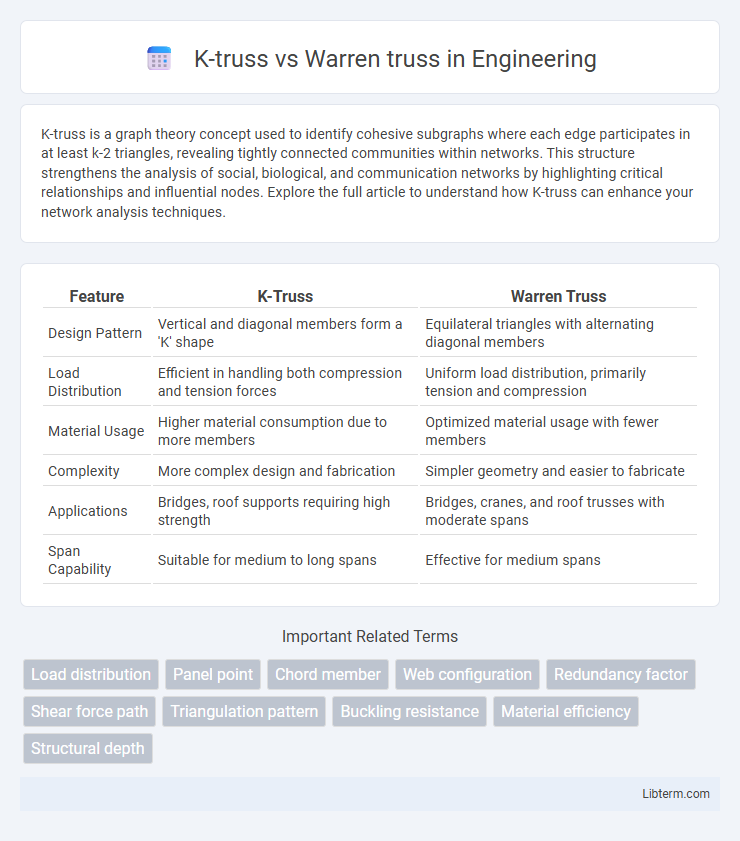

| Feature | K-Truss | Warren Truss |

|---|---|---|

| Design Pattern | Vertical and diagonal members form a 'K' shape | Equilateral triangles with alternating diagonal members |

| Load Distribution | Efficient in handling both compression and tension forces | Uniform load distribution, primarily tension and compression |

| Material Usage | Higher material consumption due to more members | Optimized material usage with fewer members |

| Complexity | More complex design and fabrication | Simpler geometry and easier to fabricate |

| Applications | Bridges, roof supports requiring high strength | Bridges, cranes, and roof trusses with moderate spans |

| Span Capability | Suitable for medium to long spans | Effective for medium spans |

Introduction to K-Truss and Warren Truss

K-Truss and Warren Truss are crucial structural frameworks used in bridges and buildings, each designed to distribute loads efficiently. The K-Truss features vertical members and diagonals forming a series of "K" shapes, providing enhanced rigidity and load distribution, ideal for long spans and heavy loads. The Warren Truss, characterized by its equilateral triangles formed by alternating diagonal members, offers simplicity and uniform stress distribution, making it cost-effective and widely used in various engineering applications.

Structural Design Principles

K-truss employs diagonal members forming a "K" shape within each panel to improve load distribution and reduce bending moments, resulting in enhanced stiffness and efficient material usage. Warren truss features alternating equilateral triangles, creating a uniform load path through tension and compression members, optimizing forces primarily for axial stress. Structurally, K-truss offers better resistance to lateral forces due to its subdivided panels, while Warren truss excels in simplicity and balanced force distribution, influencing choices in bridges and building frameworks.

Historical Development and Usage

The K-truss, developed in the early 20th century, features diagonal members forming a "K" shape, enhancing load distribution and reducing material use compared to traditional trusses. The Warren truss, patented by James Warren in 1848, utilizes equilateral triangles for uniform stress distribution and gained widespread adoption in railway bridges and industrial structures. Both trusses represent significant milestones in structural engineering, with the Warren truss favored for simplicity and efficiency, while the K-truss is preferred in applications requiring additional stiffness and support.

Material Efficiency Comparison

K-truss structures exhibit higher material efficiency by minimizing member lengths and using fewer diagonal elements, reducing overall weight without compromising load distribution. Warren trusses, characterized by equilateral triangles, provide uniform stress distribution but often require more material due to longer diagonal members and additional bracing. Optimizing for material efficiency, K-trusses are preferred in applications demanding lighter structures with comparable strength, while Warren trusses excel in simplicity and ease of fabrication.

Load Distribution Characteristics

K-truss structures exhibit superior load distribution characteristics by effectively channeling forces through shorter, interconnected members, reducing stress concentrations and enhancing overall stability. Warren truss designs distribute loads evenly across equilateral triangles, promoting efficient tension and compression flow but may experience higher bending stresses in longer members. The K-truss's enhanced redundancy and distributed load paths often result in improved handling of dynamic and concentrated loads compared to the simpler, more uniform load paths of the Warren truss.

Applications in Modern Engineering

K-truss and Warren truss designs serve distinct roles in modern engineering applications, with K-truss commonly used in bridges and buildings requiring high load distribution efficiency and resistance to dynamic forces. Warren truss, characterized by its equilateral triangle pattern, is favored for applications in roof structures, aircraft wings, and highway bridges due to its simplicity, material efficiency, and ability to evenly distribute stress. Both trusses optimize structural stability but are chosen based on the specific load conditions, span length, and architectural requirements in contemporary construction projects.

Advantages of K-Truss Systems

K-truss systems provide enhanced load distribution and greater structural stability compared to Warren trusses due to their additional diagonal members forming a K shape, which minimizes deflection under heavy loads. The increased redundancy in K-truss designs improves fault tolerance and safety, making them ideal for long-span bridges and buildings requiring high durability. Their ability to efficiently handle both tension and compression forces results in optimized material use and reduced maintenance costs over time.

Benefits of Warren Truss Structures

Warren truss structures offer significant benefits due to their efficient use of materials and evenly distributed loads, which reduce stress concentrations and enhance overall stability. The simple triangular pattern minimizes the number of members required, lowering weight and construction costs while maintaining high strength. This design also allows for easier fabrication and maintenance, making Warren trusses ideal for bridges and large-span buildings.

Limitations and Challenges

K-truss structures face limitations such as increased complexity in design and fabrication due to the diagonal members forming a "K" shape, which can lead to higher material usage and difficulties in load distribution analysis. Warren truss challenges include susceptibility to buckling under compressive forces in members due to its equilateral triangular pattern, which may require additional bracing or reinforcement for stability. Both truss types encounter challenges in optimizing weight-to-strength ratio while maintaining structural integrity under dynamic loads.

Choosing the Right Truss for Your Project

K-truss offers superior load distribution with its diagonal web members forming a "K" shape, making it ideal for projects requiring enhanced stability under heavy loads. Warren truss features equilateral triangles that efficiently spread forces, providing a lightweight design suitable for longer spans and cost-effective construction. Selecting between K-truss and Warren truss depends on factors like load requirements, span length, material efficiency, and budget constraints.

K-truss Infographic

libterm.com

libterm.com