Jewel bearings are precision components made from synthetic sapphire or ruby, used primarily in high-quality mechanical watches and instruments to reduce friction and wear. Their hardness and smooth surfaces ensure long-lasting durability and accurate movement by minimizing resistance in rotating parts. Discover how jewel bearings enhance performance and why they are crucial in precise engineering by reading the full article.

Table of Comparison

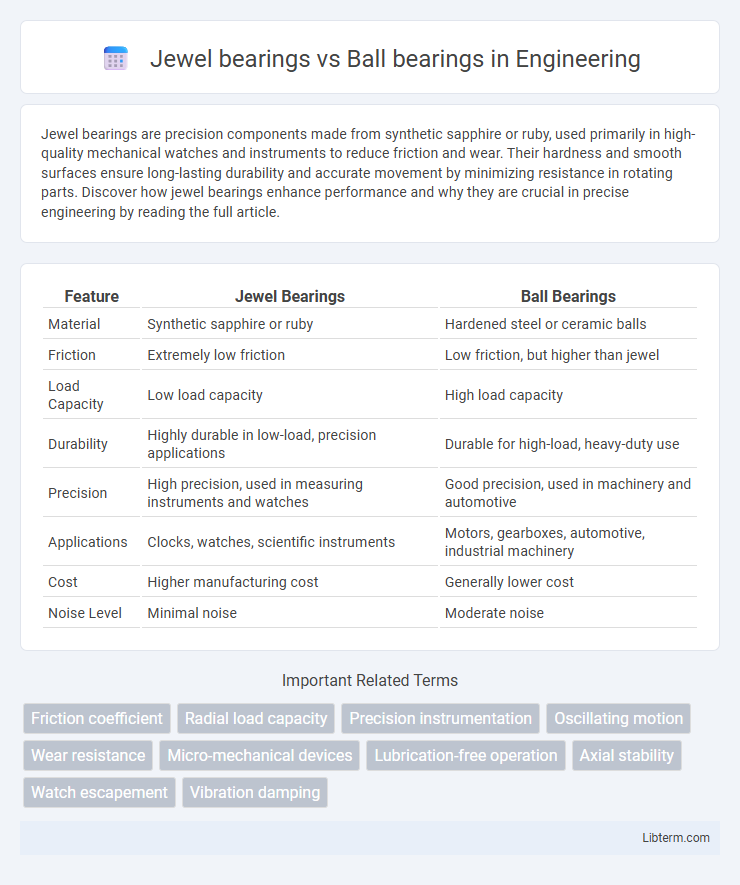

| Feature | Jewel Bearings | Ball Bearings |

|---|---|---|

| Material | Synthetic sapphire or ruby | Hardened steel or ceramic balls |

| Friction | Extremely low friction | Low friction, but higher than jewel |

| Load Capacity | Low load capacity | High load capacity |

| Durability | Highly durable in low-load, precision applications | Durable for high-load, heavy-duty use |

| Precision | High precision, used in measuring instruments and watches | Good precision, used in machinery and automotive |

| Applications | Clocks, watches, scientific instruments | Motors, gearboxes, automotive, industrial machinery |

| Cost | Higher manufacturing cost | Generally lower cost |

| Noise Level | Minimal noise | Moderate noise |

Introduction to Jewel Bearings and Ball Bearings

Jewel bearings are precision components typically made from synthetic sapphire or ruby, prized for their low friction and high wear resistance in delicate instruments like watches and gyroscopes. Ball bearings consist of steel or ceramic balls enclosed in races, engineered to reduce rotational friction and support radial and axial loads across a wide range of machinery and vehicles. Each bearing type serves distinct applications, with jewel bearings favored in high-precision, low-load environments and ball bearings optimized for high-speed, heavy-load mechanical systems.

Historical Development and Applications

Jewel bearings, developed in the 18th century, were initially used in precision timepieces to reduce friction and wear with their synthetic sapphire or ruby components, enabling highly accurate mechanical movements. Ball bearings, invented in the late 19th century by Philip Vaughan, provided broader industrial applications, including automotive, aerospace, and manufacturing, by offering increased load capacity and rotational speed with steel balls housed in races. While jewel bearings remain essential in horology and sensitive instrumentation, ball bearings dominate heavy-duty machinery and high-speed rotary systems due to their durability and versatility.

Material Composition and Structure

Jewel bearings are composed primarily of synthetic sapphire or ruby, which provide exceptional hardness and low friction due to their crystalline structure, making them ideal for precision instruments like watches. Ball bearings consist of steel or ceramic balls housed in metal races that facilitate rotational motion by reducing friction between moving parts. While jewel bearings rely on the rigidity and smoothness of gemstone materials, ball bearings depend on the optimized geometry of spherical elements and raceways to distribute load and minimize wear.

Operating Principle: How Each Bearing Works

Jewel bearings operate by suspending a rotating shaft on a polished jewel, such as synthetic sapphire or ruby, which significantly reduces friction through a smooth, hard surface contact point. Ball bearings function by placing a series of spherical balls between two rings, allowing rotational movement with minimal friction as the balls roll and distribute loads evenly. The primary distinction lies in jewel bearings providing precision with minimal wear in low-load applications, whereas ball bearings accommodate higher loads and speeds through rolling elements.

Performance in Precision Instruments

Jewel bearings offer superior friction reduction and wear resistance in precision instruments, enabling high sensitivity and accuracy essential for fine measurements such as in mechanical watches and scientific devices. Ball bearings, while effective in minimizing rotational friction, generally exhibit higher friction levels and greater wear over time, potentially compromising long-term precision in delicate applications. The choice between jewel and ball bearings directly impacts the durability and performance stability of precision instruments.

Durability and Lifespan Comparison

Jewel bearings, typically made from synthetic sapphire or ruby, offer exceptional wear resistance and maintain precise tolerances over time, leading to superior durability compared to ball bearings. Ball bearings, composed of hardened steel or ceramic, provide good durability but are more susceptible to wear and deformation under continuous heavy loads. The lifespan of jewel bearings generally surpasses that of ball bearings in precision instruments, as their low friction and hardness reduce wear and extend operational life.

Friction and Wear Characteristics

Jewel bearings exhibit ultra-low friction and exceptional wear resistance due to their hard, smooth synthetic sapphire or ruby contact surfaces, making them ideal for precision instruments and timepieces. Ball bearings, typically made of hardened steel or ceramic, offer low friction and durability in high-speed, high-load applications but may experience greater wear over time compared to jewel bearings. The reduced friction and minimal wear of jewel bearings contribute to enhanced accuracy and longevity in delicate mechanisms, while ball bearings balance performance and cost for diverse industrial uses.

Cost Considerations and Availability

Jewel bearings, often made from synthetic sapphire or ruby, are significantly more expensive due to their precision manufacturing and material costs, limiting their availability mainly to high-end watches and scientific instruments. Ball bearings, composed of steel or ceramic, offer a cost-effective and widely available solution suitable for diverse industrial applications ranging from automotive to machinery. This cost disparity influences the choice of bearing type based on budget constraints, required durability, and application-specific needs.

Common Industries and Use Cases

Jewel bearings, known for their high precision and low friction, are predominantly used in watchmaking, medical instruments, and scientific equipment where accuracy and durability at micro scales are critical. Ball bearings, offering versatility and load capacity, dominate automotive, aerospace, and heavy machinery industries due to their ability to support radial and axial loads under varying speeds and conditions. Both bearing types optimize performance but cater to distinct operational demands across precision instrumentation and industrial machinery sectors.

Choosing the Right Bearing for Your Application

Jewel bearings offer superior precision and low friction ideal for high-accuracy instruments like watches and measuring devices, while ball bearings excel in handling heavier loads and higher speeds in machinery and automotive applications. Selecting the right bearing depends on factors such as load capacity, rotational speed, friction requirements, and environmental conditions. For delicate, high-precision tasks, jewel bearings provide minimal wear and enhanced stability, whereas ball bearings deliver durability and versatility in more demanding industrial environments.

Jewel bearings Infographic

libterm.com

libterm.com