Ultimate tensile strength represents the maximum stress a material can withstand while being stretched or pulled before breaking. This property is crucial for assessing the durability and performance of metals, plastics, and composites under mechanical loads. Explore the rest of the article to understand how ultimate tensile strength impacts your material selection and engineering design.

Table of Comparison

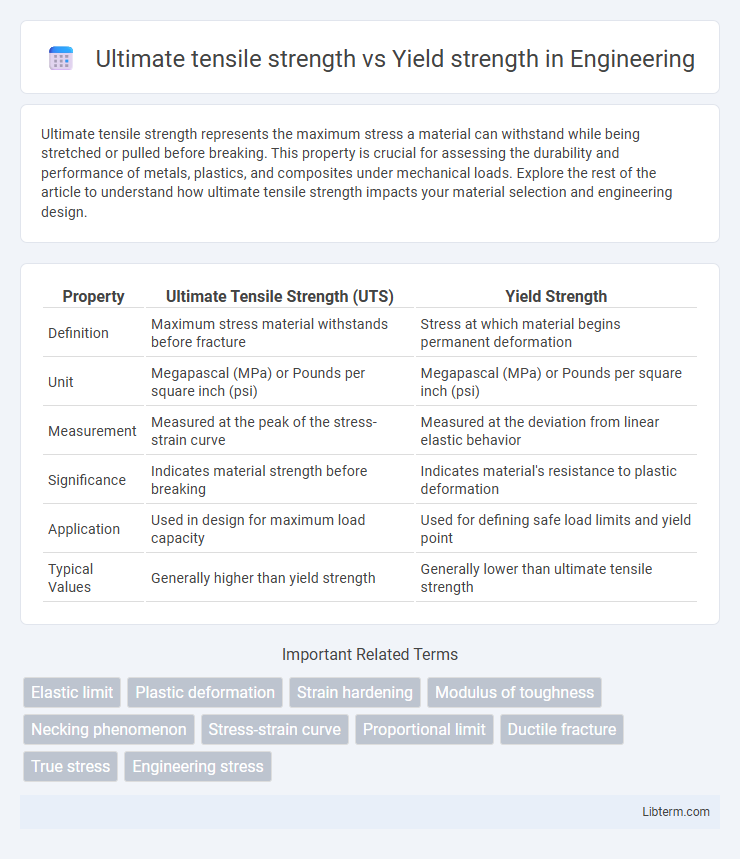

| Property | Ultimate Tensile Strength (UTS) | Yield Strength |

|---|---|---|

| Definition | Maximum stress material withstands before fracture | Stress at which material begins permanent deformation |

| Unit | Megapascal (MPa) or Pounds per square inch (psi) | Megapascal (MPa) or Pounds per square inch (psi) |

| Measurement | Measured at the peak of the stress-strain curve | Measured at the deviation from linear elastic behavior |

| Significance | Indicates material strength before breaking | Indicates material's resistance to plastic deformation |

| Application | Used in design for maximum load capacity | Used for defining safe load limits and yield point |

| Typical Values | Generally higher than yield strength | Generally lower than ultimate tensile strength |

Introduction to Tensile and Yield Strength

Ultimate tensile strength (UTS) measures the maximum stress a material can withstand before failure, indicating its overall durability under tension. Yield strength defines the stress level at which a material begins to deform plastically, marking the limit between elastic and permanent deformation. Both tensile and yield strength are critical parameters in material science and engineering, guiding the selection of metals, alloys, and composites for structural applications.

Definitions: Ultimate Tensile Strength vs Yield Strength

Ultimate tensile strength (UTS) refers to the maximum stress a material can withstand while being stretched or pulled before breaking, indicating its overall maximum load capacity. Yield strength is the stress level at which a material begins to deform plastically, marking the transition from elastic deformation to permanent deformation. Understanding the difference between UTS and yield strength is crucial for selecting materials that must endure specific load limits without permanent damage.

Key Differences Between Ultimate Tensile Strength and Yield Strength

Ultimate tensile strength (UTS) represents the maximum stress a material can withstand while being stretched before breaking, whereas yield strength marks the stress level at which a material begins to deform plastically and will not return to its original shape. UTS measures the peak load-bearing capacity during tensile testing, while yield strength indicates the elastic limit, providing critical data for designing structures to prevent permanent deformation. These properties are essential for engineers to determine material suitability under different loading conditions, ensuring safety and performance.

Importance in Material Selection and Engineering

Ultimate tensile strength (UTS) and yield strength are critical parameters in material selection and engineering design, determining a material's ability to withstand applied forces without failure or permanent deformation. Yield strength indicates the stress level at which a material begins to deform plastically, essential for ensuring structural components maintain their shape under service loads. Ultimate tensile strength represents the maximum stress a material can endure before breaking, crucial for assessing safety margins and preventing catastrophic failure in engineering applications.

How Ultimate Tensile Strength is Measured

Ultimate tensile strength (UTS) is measured by subjecting a material specimen to a controlled tensile load until it breaks, recording the maximum stress endured just before fracture. This is performed using a universal testing machine that continuously elongates the specimen while measuring the applied force and corresponding elongation. The UTS value represents the peak stress on the engineering stress-strain curve, providing critical data for material strength and failure prediction.

Measuring Yield Strength: Methods and Standards

Measuring yield strength involves methods such as the offset method, typically using a 0.2% strain offset to determine the stress at which a material begins plastic deformation, adhering to standards like ASTM E8/E8M for metals. The use of tensile testing machines allows precise control of load and strain rates to accurately capture the yield point, which is critical for materials without a clear yield plateau. International standards such as ISO 6892 complement these procedures, ensuring consistent and repeatable measurements across different testing environments.

Stress-Strain Curve: Visualizing UTS and Yield Points

The stress-strain curve distinctly illustrates the ultimate tensile strength (UTS) as the highest point of stress a material can endure before necking begins, whereas the yield strength marks the stress level at which permanent deformation initiates. UTS represents the maximum stress before failure, crucial for determining material limits under tension, while yield strength indicates the transition from elastic to plastic deformation. Accurate identification of these points on the curve enables engineers to predict material behavior under load and design components for safety and performance.

Factors Affecting UTS and Yield Strength in Materials

Ultimate tensile strength (UTS) and yield strength in materials are influenced by factors such as alloy composition, heat treatment, and microstructure, which alter dislocation movement and grain boundary characteristics. Processing techniques like cold working increase yield strength by introducing strain hardening, while temperature variations affect both UTS and yield strength by modifying the material's ductility and phase stability. The presence of defects, impurities, and precipitates also play a critical role in determining the stress levels at which a material will yield or ultimately fail.

Applications Where UTS vs Yield Strength Matter

Ultimate tensile strength (UTS) measures the maximum stress a material can withstand before failure, while yield strength indicates the stress at which a material begins to deform plastically. Applications in aerospace and automotive industries prioritize yield strength for component design to ensure structural integrity under operational loads without permanent deformation. In contrast, UTS is critical in material selection for safety-critical components like bridge cables and pressure vessels, where resistance to fracture after maximum load is essential.

Summary: Choosing Materials Based on Strength Requirements

Ultimate tensile strength indicates the maximum stress a material can withstand before breaking, while yield strength marks the stress level at which it begins to deform permanently. Selecting materials requires balancing these properties according to application needs, ensuring the material can endure operational loads without failure or excessive deformation. Engineers prioritize yield strength for structural safety and ultimate tensile strength for durability in high-stress environments.

Ultimate tensile strength Infographic

libterm.com

libterm.com