Magnetic seals offer superior airtight and watertight protection by utilizing magnetic force to create a secure closure, enhancing durability and efficiency in various applications such as refrigerators and industrial equipment. Their easy installation and low maintenance make them an ideal choice for reducing energy loss and preventing contamination. Discover how magnetic seals can improve your devices and explore their benefits in the rest of this article.

Table of Comparison

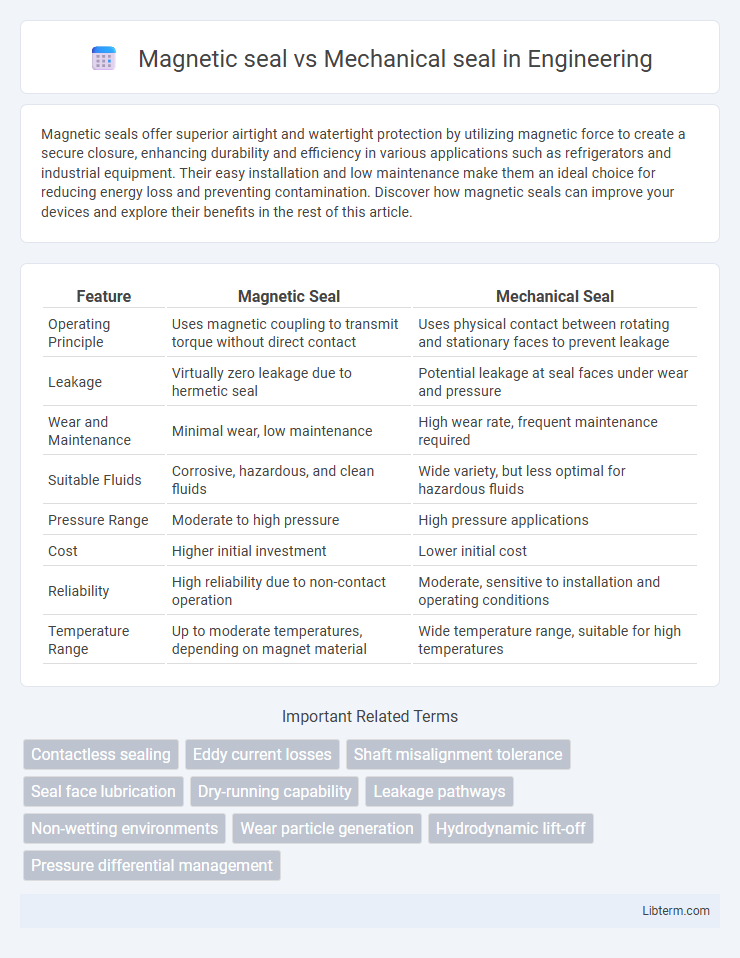

| Feature | Magnetic Seal | Mechanical Seal |

|---|---|---|

| Operating Principle | Uses magnetic coupling to transmit torque without direct contact | Uses physical contact between rotating and stationary faces to prevent leakage |

| Leakage | Virtually zero leakage due to hermetic seal | Potential leakage at seal faces under wear and pressure |

| Wear and Maintenance | Minimal wear, low maintenance | High wear rate, frequent maintenance required |

| Suitable Fluids | Corrosive, hazardous, and clean fluids | Wide variety, but less optimal for hazardous fluids |

| Pressure Range | Moderate to high pressure | High pressure applications |

| Cost | Higher initial investment | Lower initial cost |

| Reliability | High reliability due to non-contact operation | Moderate, sensitive to installation and operating conditions |

| Temperature Range | Up to moderate temperatures, depending on magnet material | Wide temperature range, suitable for high temperatures |

Introduction to Magnetic and Mechanical Seals

Magnetic seals use a magnetic field to create a leak-proof barrier between rotating and stationary components, enhancing durability and reducing wear in dynamic environments. Mechanical seals rely on precisely machined surfaces that press against each other to prevent fluid leakage, commonly found in pumps and compressors. Both seal types are essential in industrial applications, offering distinct advantages based on pressure, temperature, and maintenance requirements.

How Magnetic Seals Work

Magnetic seals operate through a sealed magnet system that creates a strong, leak-proof barrier by aligning magnetic fields within the rotating and stationary components, preventing fluid escape without direct contact. The magnetic coupling eliminates wear and friction, enhancing durability and reducing maintenance compared to mechanical seals that rely on physical contact between sealing faces. This non-contact sealing mechanism ensures optimal performance in aggressive chemical environments and high-speed applications, making magnetic seals ideal for pumps and mixers handling hazardous or sensitive fluids.

How Mechanical Seals Function

Mechanical seals function by creating a tight barrier between the rotating shaft and the stationary pump housing, preventing fluid leakage. They consist of two flat sealing faces, one attached to the shaft and the other to the pump casing, which maintain contact through a combination of spring pressure and hydrodynamic forces. This contact forms a reliable seal even under varying pressure and temperature conditions, making mechanical seals essential in many industrial applications for ensuring fluid containment and reducing maintenance.

Key Differences Between Magnetic and Mechanical Seals

Magnetic seals utilize magnetic force to create a non-contact sealing interface, minimizing wear and extending seal life, while mechanical seals rely on physical contact between rotating and stationary components, which can lead to higher friction and wear over time. Magnetic seals offer superior resistance to leakage and contamination, making them ideal for applications involving hazardous fluids, whereas mechanical seals require frequent maintenance due to their susceptibility to wear and failure. The cost of magnetic seals is generally higher upfront, but their durability and reduced downtime provide long-term cost savings compared to mechanical seals.

Performance Comparison: Durability and Reliability

Magnetic seals exhibit superior durability due to their non-contact design, which minimizes wear and extends operational life compared to mechanical seals that rely on physical contact and are prone to faster degradation. Reliability in magnetic seals is enhanced by their resistance to leakage and reduced maintenance requirements, making them ideal for harsh industrial environments. Mechanical seals, while effective in many applications, often require frequent adjustments and replacements, impacting overall system uptime and cost-efficiency.

Installation and Maintenance Requirements

Magnetic seals require precise alignment but offer easier installation due to their contactless operation, reducing wear and the risk of leakage. Mechanical seals demand more complex installation with careful adjustment of components to prevent damage and ensure proper sealing, often needing specialized tools. Maintenance of magnetic seals typically involves less frequent intervention as they experience minimal friction, whereas mechanical seals require regular inspection and replacement of parts to address wear and potential seal failure.

Leakage Prevention: Which Seal Performs Better?

Magnetic seals offer superior leakage prevention due to their non-contact operation, minimizing wear and maintaining a consistent seal even under high pressure or temperature fluctuations. Mechanical seals, while effective in many applications, are prone to wear and leakage over time because of direct contact between sealing surfaces. Industrial studies show magnetic seals reduce leakage rates by up to 90% compared to traditional mechanical seals, making them a preferred choice for critical fluid containment systems.

Typical Applications for Magnetic and Mechanical Seals

Magnetic seals are typically used in applications requiring leak-free containment of hazardous fluids, such as in chemical reactors, pharmaceutical manufacturing, and vacuum pumps, where non-contact sealing reduces wear and maintenance. Mechanical seals are commonly found in pumps, compressors, and mixers in industries like oil and gas, water treatment, and food processing, providing reliable sealing under high pressure and temperature conditions. Both seal types enhance equipment lifespan, but magnetic seals excel in corrosive or sterile environments while mechanical seals offer robust performance in heavy-duty, abrasive settings.

Cost Analysis: Initial Investment and Long-Term Value

Magnetic seals typically have a higher initial investment due to advanced materials and manufacturing complexity, but they offer lower maintenance costs and longer service life compared to mechanical seals. Mechanical seals, while less expensive upfront, often incur higher long-term expenses from frequent replacements and downtime. Considering total cost of ownership, magnetic seals provide superior long-term value in applications with demanding operating conditions.

Choosing the Right Seal for Your Application

Choosing the right seal between magnetic seal and mechanical seal depends on factors like operating pressure, temperature, and fluid compatibility. Magnetic seals offer leak-free performance and low maintenance for corrosive or hazardous fluids, while mechanical seals provide robust durability under high pressure and temperature conditions. Evaluating application-specific requirements such as torque, shaft speed, and environmental exposure ensures optimal seal selection for reliability and efficiency.

Magnetic seal Infographic

libterm.com

libterm.com