Manual control allows precise, hands-on operation of devices, enhancing user engagement and immediate response to changes. It provides direct interaction with machinery or systems, which is ideal for tasks requiring customization or fine-tuning. Discover how mastering manual control can improve your efficiency by reading the rest of the article.

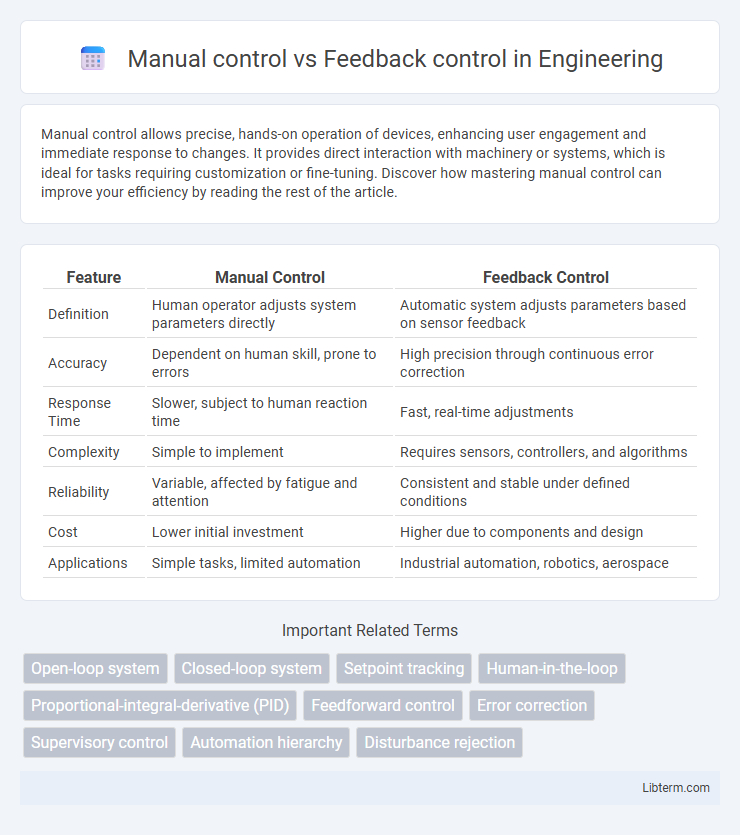

Table of Comparison

| Feature | Manual Control | Feedback Control |

|---|---|---|

| Definition | Human operator adjusts system parameters directly | Automatic system adjusts parameters based on sensor feedback |

| Accuracy | Dependent on human skill, prone to errors | High precision through continuous error correction |

| Response Time | Slower, subject to human reaction time | Fast, real-time adjustments |

| Complexity | Simple to implement | Requires sensors, controllers, and algorithms |

| Reliability | Variable, affected by fatigue and attention | Consistent and stable under defined conditions |

| Cost | Lower initial investment | Higher due to components and design |

| Applications | Simple tasks, limited automation | Industrial automation, robotics, aerospace |

Introduction to Manual and Feedback Control

Manual control involves human operators directly adjusting system inputs based on observed outputs, relying heavily on human judgment and experience. Feedback control uses sensors and automatic control loops to continuously monitor system performance and make real-time corrections, enhancing precision and stability. This distinction forms the foundation for designing efficient control systems in industrial and technological applications.

Definition of Manual Control

Manual control refers to the direct human operation of a system or device without automated assistance, requiring continuous input and adjustment from the operator. It relies on human sensory feedback and decision-making to maintain desired performance, often used in scenarios where precision or adaptability is critical. Manual control contrasts with feedback control systems that use sensors and controllers to automatically regulate processes.

Definition of Feedback Control

Feedback control is a system regulation method where the output is continuously monitored and compared to a desired setpoint, allowing automatic adjustments to minimize error and achieve stable performance. It contrasts with manual control, where a human operator adjusts inputs based on observed outputs without automated error correction. Feedback control systems are essential in applications requiring precision, such as industrial automation, robotics, and process control.

Key Differences Between Manual and Feedback Control

Manual control relies on human operators to monitor and adjust system variables, resulting in slower response times and potential for human error. Feedback control employs sensors and automatic adjustments to maintain system stability and performance by continuously comparing output to a desired setpoint. The primary difference lies in feedback control's ability to react dynamically to disturbances, whereas manual control depends on subjective human intervention.

Advantages of Manual Control

Manual control allows operators to make real-time adjustments based on intuition and experience, enhancing flexibility in dynamic environments. It requires minimal setup and lower initial costs compared to automated feedback systems, making it ideal for simple or low-volume processes. Operators can quickly respond to unexpected conditions without relying on sensors or algorithms, improving responsiveness in critical situations.

Advantages of Feedback Control

Feedback control offers precise adjustment by continuously monitoring output and automatically correcting deviations from setpoints, increasing system stability and accuracy. It reduces human error and labor by automating response actions, enhancing operational efficiency in dynamic environments. This control method adapts to disturbances and system changes, ensuring consistent performance across various applications, including manufacturing, robotics, and process control.

Limitations of Manual Control

Manual control is limited by human reaction time, variability in skill, and fatigue, leading to inconsistent system performance and slower response to disturbances. In complex or fast-changing environments, operators may struggle to maintain stability and precision, increasing the risk of errors. Unlike automated feedback control, manual control lacks continuous real-time adjustment, resulting in less efficient error correction and system optimization.

Limitations of Feedback Control

Feedback control systems often face limitations such as delays in response time, which can cause instability or oscillations in dynamic environments. Sensitivity to sensor inaccuracies and external disturbances may degrade performance, leading to erroneous corrections and system inefficiencies. Additionally, feedback control may struggle with nonlinearities and unmodeled dynamics, restricting its effectiveness in complex or rapidly changing processes.

Applications of Manual and Feedback Control Systems

Manual control systems are widely used in applications where human judgment and adaptability are crucial, such as in driving vehicles, operating machinery, and managing emergency responses. Feedback control systems dominate in automated environments requiring precision and stability, including industrial process control, climate regulation in HVAC systems, and robotic automation. These systems enhance performance by continuously adjusting outputs based on sensor inputs to maintain desired setpoints.

Choosing the Right Control Strategy

Choosing the right control strategy depends on system complexity and desired precision; manual control suits simple, low-speed applications with human intervention, while feedback control excels in automated, dynamic environments requiring real-time adjustments. Feedback control systems use sensors and closed-loop mechanisms to maintain stability and accuracy despite disturbances. Evaluating factors such as response time, error tolerance, and operational consistency helps determine whether manual oversight or automated feedback offers optimal performance.

Manual control Infographic

libterm.com

libterm.com