Mortise and tenon joints are a traditional woodworking technique renowned for their strength and durability, commonly used in furniture and timber framing. This joint involves inserting a protruding tenon into a corresponding mortise hole, creating a secure connection without the need for nails or screws. Explore the article to discover expert tips on crafting and applying mortise and tenon joints in your woodworking projects.

Table of Comparison

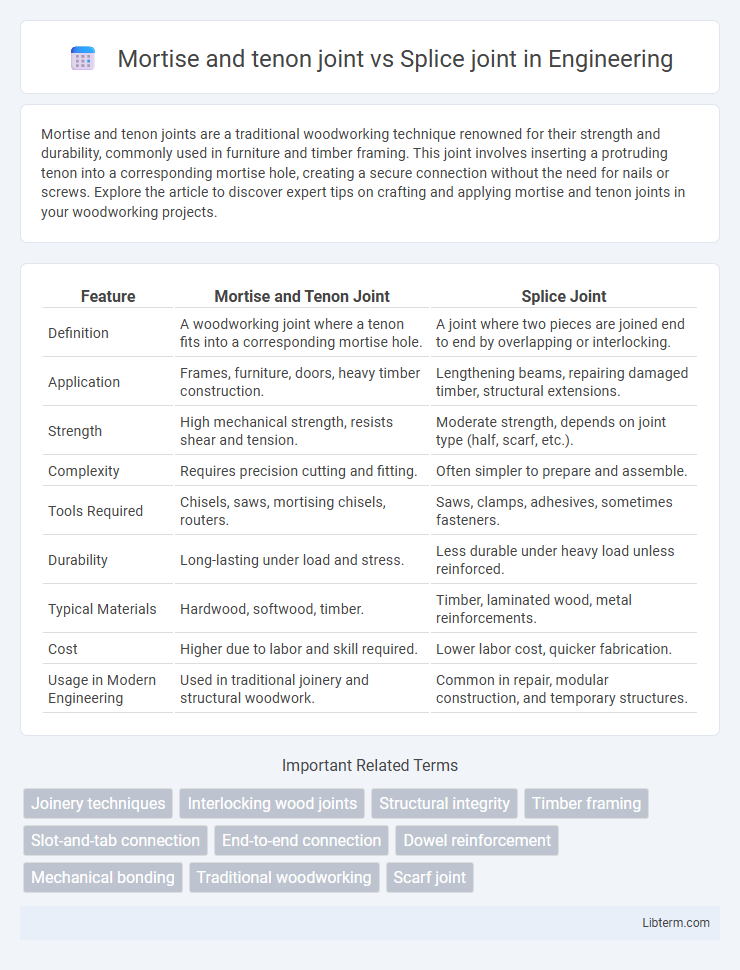

| Feature | Mortise and Tenon Joint | Splice Joint |

|---|---|---|

| Definition | A woodworking joint where a tenon fits into a corresponding mortise hole. | A joint where two pieces are joined end to end by overlapping or interlocking. |

| Application | Frames, furniture, doors, heavy timber construction. | Lengthening beams, repairing damaged timber, structural extensions. |

| Strength | High mechanical strength, resists shear and tension. | Moderate strength, depends on joint type (half, scarf, etc.). |

| Complexity | Requires precision cutting and fitting. | Often simpler to prepare and assemble. |

| Tools Required | Chisels, saws, mortising chisels, routers. | Saws, clamps, adhesives, sometimes fasteners. |

| Durability | Long-lasting under load and stress. | Less durable under heavy load unless reinforced. |

| Typical Materials | Hardwood, softwood, timber. | Timber, laminated wood, metal reinforcements. |

| Cost | Higher due to labor and skill required. | Lower labor cost, quicker fabrication. |

| Usage in Modern Engineering | Used in traditional joinery and structural woodwork. | Common in repair, modular construction, and temporary structures. |

Introduction to Mortise and Tenon vs Splice Joints

Mortise and tenon joints are traditional woodworking techniques characterized by a rectangular projection (tenon) fitting snugly into a corresponding cavity (mortise), providing superior strength and stability for frame construction. Splice joints, on the other hand, involve joining two pieces end-to-end to extend length but generally offer less mechanical strength and are often reinforced with dowels, screws, or adhesives. Understanding the differences in load-bearing capacity and application is crucial for selecting the appropriate joint in furniture making and structural carpentry.

Historical Background of Wood Joinery

Mortise and tenon joints have a rich historical background, dating back over 7,000 years and widely used in ancient Egyptian and Chinese woodworking for strong, durable connections. Splice joints, on the other hand, emerged later as practical solutions in timber framing and carpentry to extend or repair wooden members while maintaining structural integrity. Both joints illustrate the evolution of wood joinery techniques that balance strength and craftsmanship across different cultures and time periods.

Mortise and Tenon Joint: Structure and Function

The mortise and tenon joint features a rectangular projection (tenon) that precisely fits into a cavity (mortise) to create a strong, interlocking connection used extensively in woodworking and furniture making. This joint provides superior structural integrity by distributing stress evenly through the tenon's shoulders and mortise walls, making it ideal for load-bearing applications. Compared to splice joints, which join two end grain surfaces, mortise and tenon joints offer enhanced durability and resistance to twisting forces.

Splice Joint: Types and Applications

Splice joints are crucial in woodworking and construction for joining two pieces of wood end-to-end, commonly used to extend beams or create longer structural elements. Types of splice joints include butt splice, half-lap splice, and scarf splice, each offering varying degrees of strength and alignment based on the application. These joints are widely applied in timber framing, furniture making, and repairing damaged wooden structures where maintaining load-bearing capacity and seamless alignment is essential.

Strength and Durability Comparison

Mortise and tenon joints offer superior strength and durability due to their interlocking design, which distributes load evenly across the joint and resists shear and tensile forces effectively. Splice joints, while easier to create, typically rely on adhesive or mechanical fasteners, making them less robust under heavy or fluctuating loads and more prone to failure over time. For structural applications requiring long-term stability and resistance to stress, mortise and tenon joints are generally preferred over splice joints.

Best Uses for Mortise and Tenon Joints

Mortise and tenon joints excel in woodworking applications requiring strong, stable connections such as furniture frames, doors, and cabinetry due to their ability to bear heavy loads and resist twisting forces. This joint is ideal for structural elements where durability and precision alignment are crucial, as it creates a tight fit that enhances the overall integrity of the assembly. Unlike splice joints, which are commonly used to extend the length of wood pieces, mortise and tenon joints are preferred for joining components at right angles, providing superior strength and longevity in load-bearing constructions.

Ideal Situations for Splice Joints

Splice joints are ideal for extending the length of structural members such as beams or rods when a single piece is insufficient, providing a strong and continuous connection in applications like timber framing or metal joining. They are especially effective in scenarios requiring alignment and load transfer along the length of the materials, such as in long wooden beams for construction or rail tracks. The simplicity of splice joints makes them suitable for repairs, reducing material waste by reconnecting existing components without complex shaping.

Tools and Techniques Required

Mortise and tenon joints require precise cutting tools such as chisels, mortise machines, and tenon saws to create interlocking parts that provide strong structural connections, often demanding careful measurement and fitting. Splice joints involve cutting and aligning wood ends using hand saws, clamps, and sometimes dowel jigs or biscuits for reinforcement, prioritizing surface preparation and glue application for joint strength. Both techniques benefit from woodworking squares and marking gauges to ensure accuracy, but mortise and tenon joints typically require more specialized equipment due to their complexity.

Common Mistakes and How to Avoid Them

Common mistakes in mortise and tenon joints include inaccurate measurements and improper fit, leading to weak connections and structural instability; using dull tools can also compromise joint precision. Avoid these errors by carefully measuring and marking components, ensuring the tenon snugly fits the mortise without excessive force, and maintaining sharp, appropriate tools for clean cuts. Splice joints often suffer from misalignment and insufficient glue coverage, resulting in weak or uneven bonds; precise alignment and thorough application of adhesive are essential to prevent joint failure.

Choosing the Right Joint for Your Project

Mortise and tenon joints offer superior strength and durability, making them ideal for load-bearing furniture and structural frameworks, while splice joints are better suited for extending the length of wood with moderate strength requirements. When choosing the right joint, consider factors such as the type of wood, the load it must bear, and the precision of your woodworking tools. Mortise and tenon joints require more skill and time but provide a long-lasting connection, whereas splice joints are simpler and faster but typically less robust.

Mortise and tenon joint Infographic

libterm.com

libterm.com