Double pipe heat exchangers consist of two concentric pipes, allowing heat transfer between fluids flowing through the inner and outer tubes. They are ideal for applications requiring efficient heat exchange in a compact design, with easy maintenance and cost-effectiveness. Discover how a double pipe heat exchanger can optimize Your thermal processes by reading the full article.

Table of Comparison

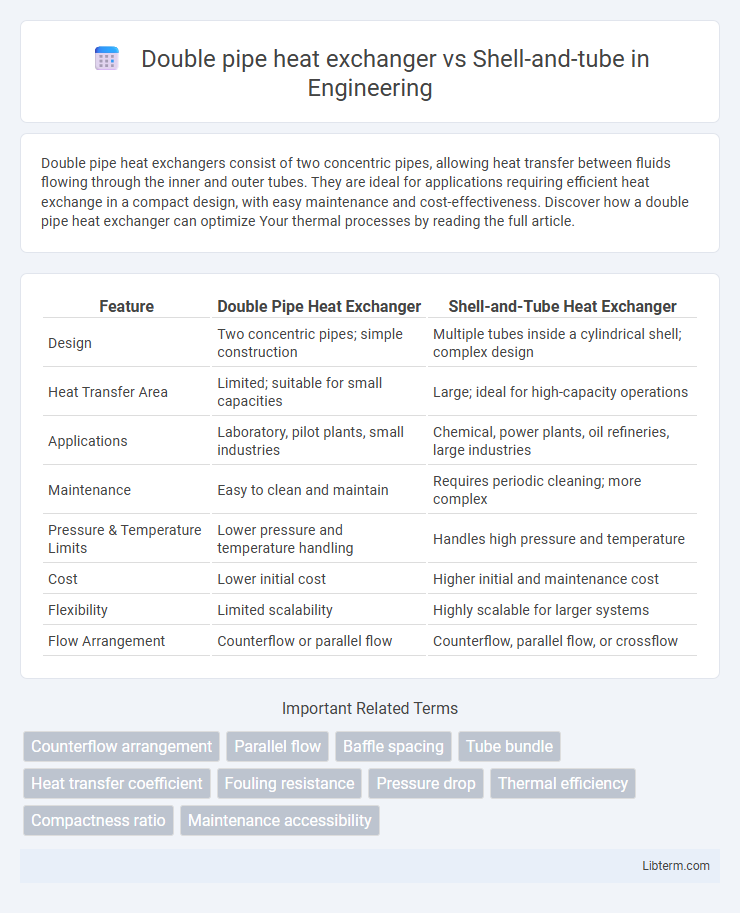

| Feature | Double Pipe Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

| Design | Two concentric pipes; simple construction | Multiple tubes inside a cylindrical shell; complex design |

| Heat Transfer Area | Limited; suitable for small capacities | Large; ideal for high-capacity operations |

| Applications | Laboratory, pilot plants, small industries | Chemical, power plants, oil refineries, large industries |

| Maintenance | Easy to clean and maintain | Requires periodic cleaning; more complex |

| Pressure & Temperature Limits | Lower pressure and temperature handling | Handles high pressure and temperature |

| Cost | Lower initial cost | Higher initial and maintenance cost |

| Flexibility | Limited scalability | Highly scalable for larger systems |

| Flow Arrangement | Counterflow or parallel flow | Counterflow, parallel flow, or crossflow |

Introduction to Double Pipe and Shell-and-Tube Heat Exchangers

Double pipe heat exchangers consist of one pipe placed inside another, enabling efficient heat transfer between two fluids with simple construction suitable for small to medium flow rates. Shell-and-tube heat exchangers feature multiple tubes enclosed within a cylindrical shell, providing a larger surface area for heat exchange ideal for high-pressure and high-temperature applications. Both types serve critical roles in industries such as chemical processing, power generation, and HVAC systems.

Design Overview of Double Pipe Heat Exchangers

Double pipe heat exchangers consist of one pipe placed concentrically inside another, allowing for the transfer of heat between two fluids flowing through the inner and outer pipes. They are characterized by their simple design, ease of fabrication, and suitability for small to moderate heat transfer duties with limited pressure and temperature conditions. Compared to shell-and-tube exchangers, double pipe designs offer better flexibility for maintenance but are less efficient for large-scale industrial applications requiring high heat transfer rates.

Design Overview of Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers consist of a series of tubes enclosed within a cylindrical shell, allowing one fluid to flow through the tubes while another fluid flows over them inside the shell, facilitating heat transfer. Their design enables handling higher pressures and temperatures compared to double pipe heat exchangers, making them suitable for large-scale industrial applications. The modular construction and availability of multiple tube passes enhance heat transfer efficiency and maintenance flexibility in shell-and-tube systems.

Working Principle: Double Pipe vs Shell-and-Tube

Double pipe heat exchangers operate by flowing two fluids through concentric pipes, allowing thermal energy transfer through the pipe wall, with one fluid inside the inner pipe and the other in the annular space. Shell-and-tube heat exchangers consist of a bundle of tubes enclosed within a cylindrical shell, where one fluid flows through the tubes and the other fluid flows over the tubes inside the shell, promoting heat transfer via direct contact with the tube surfaces. The key difference in working principle is the flow configuration: double pipe utilizes coaxial flow paths ideal for smaller capacities, whereas shell-and-tube supports higher flow rates and pressures with multiple tube passes for better heat transfer efficiency.

Heat Transfer Efficiency Comparison

Double pipe heat exchangers provide high heat transfer efficiency in processes involving small to moderate flow rates due to direct counter-flow arrangements and reduced fluid bypass effects. Shell-and-tube heat exchangers excel in large-scale industrial applications by offering greater surface area and enhanced turbulence, which significantly boosts overall heat transfer rates. Efficiency depends heavily on design parameters such as tube diameter, flow velocity, and temperature gradients, with shell-and-tube designs typically outperforming double pipe units in handling higher heat loads and complex fluid mixtures.

Space and Installation Requirements

Double pipe heat exchangers require significantly less installation space compared to shell-and-tube models due to their compact, tubular design ideal for smaller capacity applications. Shell-and-tube heat exchangers demand more space because of their larger footprint and complex assembly involving multiple tubes within a cylindrical shell. Installation of double pipe exchangers is simpler and quicker, benefiting from straightforward piping connections, whereas shell-and-tube systems often require extensive support structures and precise alignment during setup.

Maintenance and Cleaning Considerations

Double pipe heat exchangers feature straightforward design with easily accessible tubes, simplifying maintenance and cleaning tasks while allowing quick disassembly for inspection. Shell-and-tube heat exchangers present more complex construction, requiring specialized tools and procedures for cleaning inner tubes and shells, often utilizing mechanical or chemical cleaning methods. The choice between these types hinges on maintenance frequency, accessibility needs, and the scale of cleaning operations suitable for the industrial application.

Typical Applications in Industry

Double pipe heat exchangers are commonly used in industries requiring efficient heat transfer for small to medium flow rates, such as chemical processing, pharmaceuticals, and food production, where precise temperature control is essential. Shell-and-tube heat exchangers dominate large-scale applications like power plants, oil refineries, and HVAC systems due to their ability to handle high pressure and temperature variations with extensive heat transfer surface areas. Both types offer robust solutions, but shell-and-tube units excel in heavy-duty, high-capacity operations, while double pipe exchangers provide compact and cost-effective options for specialized process control.

Cost Analysis: Initial Investment and Operation

Double pipe heat exchangers generally have a lower initial investment cost compared to shell-and-tube heat exchangers due to simpler design and smaller material requirements. Operational costs for double pipe units are typically lower in low-to-medium flow applications but can increase significantly with fouling and maintenance demands. Shell-and-tube heat exchangers, although more expensive upfront, offer better efficiency and scalability for high-pressure and large-scale industrial processes, often resulting in lower long-term operational expenses.

Summary: Choosing the Right Heat Exchanger

Double pipe heat exchangers offer simple design and easy maintenance, making them ideal for small-scale or low flow applications requiring precise temperature control. Shell-and-tube heat exchangers provide higher heat transfer efficiency and handle larger volumes, suitable for industrial processes demanding high capacity and durability. Selecting the right heat exchanger depends on factors such as heat duty, space constraints, fluid properties, and maintenance considerations.

Double pipe heat exchanger Infographic

libterm.com

libterm.com