SCADA systems excel in monitoring and controlling large-scale, geographically dispersed processes by providing real-time data acquisition and remote management. DCS, on the other hand, offers integrated control solutions with centralized processing, focusing on complex industrial processes within a single location. Explore the rest of the article to understand how these systems can optimize Your industrial automation strategies.

Table of Comparison

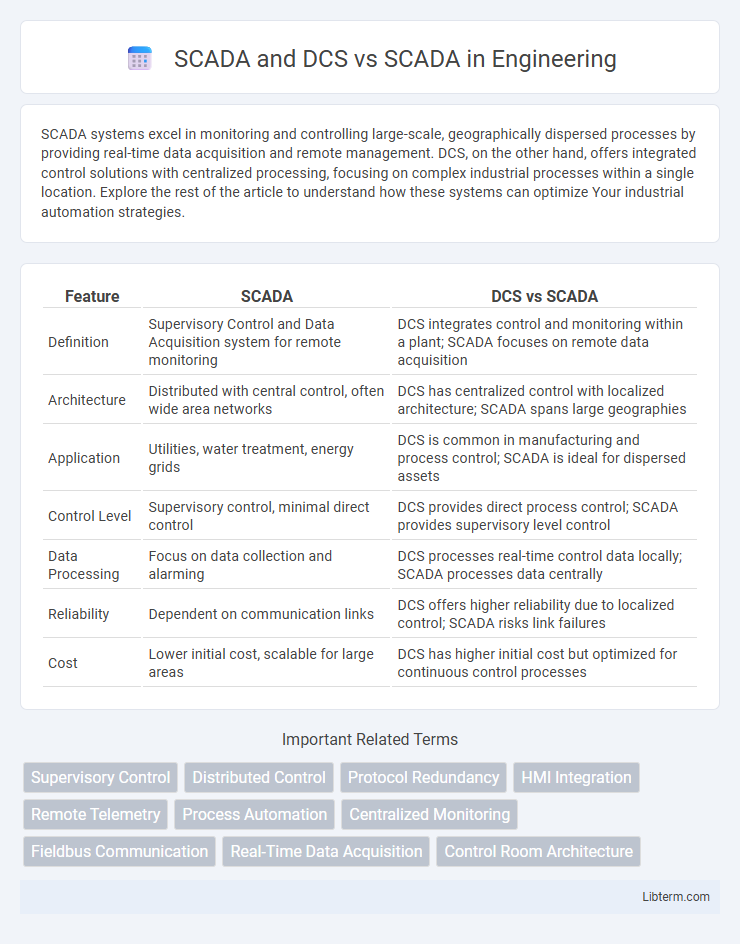

| Feature | SCADA | DCS vs SCADA |

|---|---|---|

| Definition | Supervisory Control and Data Acquisition system for remote monitoring | DCS integrates control and monitoring within a plant; SCADA focuses on remote data acquisition |

| Architecture | Distributed with central control, often wide area networks | DCS has centralized control with localized architecture; SCADA spans large geographies |

| Application | Utilities, water treatment, energy grids | DCS is common in manufacturing and process control; SCADA is ideal for dispersed assets |

| Control Level | Supervisory control, minimal direct control | DCS provides direct process control; SCADA provides supervisory level control |

| Data Processing | Focus on data collection and alarming | DCS processes real-time control data locally; SCADA processes data centrally |

| Reliability | Dependent on communication links | DCS offers higher reliability due to localized control; SCADA risks link failures |

| Cost | Lower initial cost, scalable for large areas | DCS has higher initial cost but optimized for continuous control processes |

Introduction to SCADA and DCS Systems

SCADA (Supervisory Control and Data Acquisition) systems enable real-time monitoring and control of industrial processes over geographically dispersed assets, providing centralized data collection and visualization. DCS (Distributed Control Systems) focus on localized control within a single plant or facility, integrating control loops and automation for process stability and efficiency. Both SCADA and DCS use sensors, controllers, and HMI (Human-Machine Interface) but differ in architecture, with SCADA optimized for large-scale remote operations and DCS for tight process control.

Core Functions of SCADA

SCADA (Supervisory Control and Data Acquisition) systems primarily focus on real-time data acquisition, remote monitoring, and control of industrial processes, enabling centralized management of geographically dispersed assets. Core functions include data collection from sensors, alarm management, and human-machine interface (HMI) visualization for operator decision-making. Unlike DCS (Distributed Control Systems), which emphasize process control within localized plants, SCADA excels in supervisory-level control and data analysis across wide-area networks.

Core Functions of DCS

Distributed Control Systems (DCS) primarily focus on process control and automation within industrial plants, providing centralized monitoring and control across multiple subsystems. The core functions of DCS include real-time data acquisition, precise control loops, and high reliability in managing continuous and batch processes with intricate feedback mechanisms. In contrast, SCADA systems emphasize supervisory control and data collection over large, geographically dispersed assets, prioritizing remote monitoring and alarm management over direct process control.

Key Differences: SCADA vs DCS

SCADA (Supervisory Control and Data Acquisition) systems excel in geographically dispersed monitoring, providing centralized data collection and control over wide areas like utilities and pipelines. DCS (Distributed Control Systems) are optimized for complex, continuous process control within localized manufacturing environments such as chemical plants and refineries, emphasizing high reliability and real-time automation. Key differences include SCADA's emphasis on remote telemetry and networked communication, contrasting with DCS's focus on process stability, deterministic control, and integrated subsystem management.

Architectural Comparison between SCADA and DCS

SCADA systems feature a centralized architecture with remote terminal units (RTUs) and programmable logic controllers (PLCs) communicating to a central supervisory computer, enabling wide-area monitoring and control. In contrast, DCS architecture distributes control to multiple controllers placed near the processes, ensuring localized control and high reliability within a plant. SCADA excels in geographically dispersed environments, while DCS provides tighter integration and faster response times for complex industrial processes.

Applications of SCADA in Industry

SCADA systems excel in large-scale industrial applications such as water treatment, oil and gas, and power generation by providing centralized monitoring and real-time data acquisition. Unlike DCS, which is tailored for continuous process control in manufacturing and chemical plants, SCADA systems handle geographically dispersed assets with remote communication capabilities. This makes SCADA indispensable for industries requiring extensive supervisory control and fault management across multiple sites.

Applications of DCS in Industry

Distributed Control Systems (DCS) are extensively used in industries such as oil and gas, power generation, and chemical processing for continuous and complex process control. DCS excels in managing large-scale processes with integrated automation, real-time monitoring, and precise control of multiple variables, ensuring safety and efficiency. Unlike SCADA systems, which are optimized for supervisory control and remote data acquisition, DCS provides a hierarchical control structure ideal for continuous manufacturing and process industries.

Pros and Cons: SCADA vs DCS

SCADA systems excel in providing real-time monitoring and control across geographically dispersed assets, making them ideal for infrastructure like water treatment and power distribution, while DCS is optimized for controlling complex manufacturing processes within a single location. SCADA offers greater scalability and easier integration with various devices but may lack the advanced process control capabilities and redundancy features inherent in DCS. DCS provides robust process automation with high reliability and precise control but often involves higher initial costs and less flexibility for remote operations compared to SCADA.

Integration and Interoperability Challenges

SCADA systems often face integration and interoperability challenges when combined with Distributed Control Systems (DCS) due to differing communication protocols, data formats, and proprietary technologies. The complexity arises from the need to synchronize real-time data exchange, control commands, and alarm management across heterogeneous platforms, impacting system reliability and efficiency. Addressing these challenges requires implementing standardized interfaces such as OPC UA and adopting middleware solutions to enable seamless interoperability and centralized monitoring.

Future Trends in SCADA and DCS Technologies

Future trends in SCADA and DCS technologies emphasize integration with Industrial Internet of Things (IIoT) for enhanced real-time data analytics and predictive maintenance capabilities. Advances in cloud computing and edge processing enable scalable, decentralized control systems offering improved cybersecurity and faster decision-making. Artificial intelligence and machine learning algorithms are increasingly embedded to optimize process efficiency and reduce operational downtime in both SCADA and DCS environments.

SCADA and DCS Infographic

libterm.com

libterm.com