Acoustics explores how sound waves interact with environments, affecting clarity, volume, and quality. Proper acoustic design enhances your space by minimizing noise pollution and optimizing sound distribution for comfort and productivity. Discover how mastering acoustics can transform your surroundings in the rest of this article.

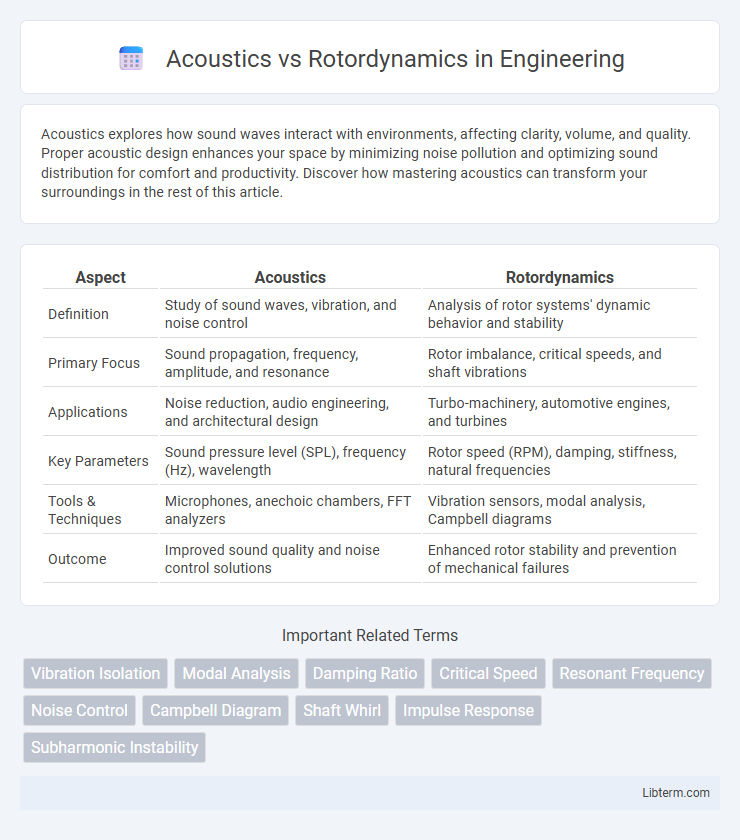

Table of Comparison

| Aspect | Acoustics | Rotordynamics |

|---|---|---|

| Definition | Study of sound waves, vibration, and noise control | Analysis of rotor systems' dynamic behavior and stability |

| Primary Focus | Sound propagation, frequency, amplitude, and resonance | Rotor imbalance, critical speeds, and shaft vibrations |

| Applications | Noise reduction, audio engineering, and architectural design | Turbo-machinery, automotive engines, and turbines |

| Key Parameters | Sound pressure level (SPL), frequency (Hz), wavelength | Rotor speed (RPM), damping, stiffness, natural frequencies |

| Tools & Techniques | Microphones, anechoic chambers, FFT analyzers | Vibration sensors, modal analysis, Campbell diagrams |

| Outcome | Improved sound quality and noise control solutions | Enhanced rotor stability and prevention of mechanical failures |

Introduction to Acoustics and Rotordynamics

Acoustics studies sound waves, their propagation, and interaction with different materials, crucial for noise control and vibration analysis in mechanical systems. Rotordynamics focuses on the behavior of rotating shafts and machinery, analyzing forces and vibrations to prevent failures and improve operational stability. Understanding the fundamentals of both fields enhances machinery design by addressing noise, vibration, and mechanical integrity simultaneously.

Fundamental Principles of Acoustics

Acoustics studies the behavior of sound waves, including their generation, propagation, and interaction with materials, governed by principles such as wave frequency, amplitude, and velocity in various media. Rotordynamics focuses on the dynamic behavior of rotating machinery, analyzing vibrations and stability influenced by rotating components, bearing forces, and aerodynamic effects. Understanding acoustics' fundamental principles assists in diagnosing noise and vibration issues in rotordynamics by revealing how sound waves result from rotor-induced vibrations and their transmission through structures.

Key Concepts in Rotordynamics

Key concepts in rotordynamics include critical speeds, unbalance response, and whirl phenomena, which influence the stability and vibration behavior of rotating machinery. Understanding shaft natural frequencies, damping mechanisms, and bearing dynamics is essential for diagnosing rotor imbalances and preventing failures. These principles differ from acoustics, which primarily focuses on sound wave propagation and noise control rather than mechanical vibration characteristics.

Differences Between Acoustics and Rotordynamics

Acoustics studies sound wave propagation, vibration, and noise control in various environments, focusing on frequency, amplitude, and wave behavior. Rotordynamics analyzes the dynamic behavior of rotating machinery components, emphasizing rotor stability, vibration modes, critical speeds, and imbalance detection. Key differences include their application domains: acoustics targets sound-related phenomena, while rotordynamics addresses mechanical vibrations and stability in rotating systems.

Applications of Acoustics in Industry

Acoustics finds critical applications in industry for noise control, machinery diagnostics, and material testing, enhancing operational efficiency and safety. Techniques such as acoustic emission monitoring are employed to detect faults and structural integrity in rotating machinery without disassembly. These acoustic methods complement rotordynamics by providing non-invasive insights into vibration and resonance phenomena in turbines, compressors, and engines.

Industrial Uses of Rotordynamics

Rotordynamics plays a critical role in industrial applications by analyzing the dynamic behavior of rotating machinery such as turbines, compressors, and pumps to prevent failures caused by imbalance, misalignment, or bearing faults. Unlike acoustics, which primarily deals with sound propagation and vibration measurement, rotordynamics focuses on rotor shaft dynamics, including critical speeds, whirl frequencies, and damping effects, ensuring operational reliability and safety. Industries like power generation, aerospace, and manufacturing rely heavily on rotordynamics for predictive maintenance and performance optimization of high-speed rotating equipment.

Analytical Techniques in Acoustics

Analytical techniques in acoustics involve mathematical modeling and signal processing methods to characterize sound wave propagation, resonance, and noise generation in various environments. These techniques utilize Fourier analysis, modal decomposition, and finite element methods to predict acoustic behavior and optimize sound quality or noise control. Compared to rotordynamics, which primarily focuses on the vibration and stability of rotating machinery, acoustics demands specialized methods for analyzing fluid-structure interaction and sound wave transmission.

Rotordynamics Analysis Methods

Rotordynamics analysis methods encompass computational techniques such as finite element analysis (FEA), Campbell diagrams, and orbit analysis to evaluate the dynamic behavior of rotating machinery. These methods focus on identifying critical speeds, vibration modes, and stability margins to prevent failures caused by imbalance, misalignment, or bearing defects. Advanced rotordynamics simulations integrate modal analysis and unbalance response analysis to optimize rotor design and enhance operational reliability.

Cross-Disciplinary Integrations

Acoustics and rotordynamics intersect through the study of vibration and noise generation in rotating machinery, where acoustic emissions provide critical diagnostic insights into rotor imbalance, misalignment, and bearing defects. Cross-disciplinary integration leverages computational fluid dynamics, signal processing, and mechanical engineering to model and mitigate aeroacoustic noise while enhancing rotor stability and performance. Advances in sensor technology and machine learning enable real-time monitoring and predictive maintenance, reducing operational risks and extending the lifespan of turbomachinery and industrial rotors.

Future Trends in Acoustics and Rotordynamics

Future trends in acoustics emphasize advanced noise control technologies and smart materials that actively dampen vibrations to improve sound quality and reduce environmental noise pollution. In rotordynamics, predictive maintenance powered by AI and real-time sensor data enhances the monitoring and diagnosis of rotor system failures, extending machinery lifespan and operational efficiency. Integration of multidisciplinary simulations combining acoustics and rotordynamics drives innovations in aerospace, automotive, and industrial applications, ensuring safer and quieter rotating machinery.

Acoustics Infographic

libterm.com

libterm.com