A linkage mechanism consists of interconnected components designed to transmit motion and force within machines, enabling complex movements through simple inputs. These mechanisms convert rotational motion to linear motion or alter the direction and magnitude of applied forces, optimizing mechanical performance in various applications. Explore the rest of the article to understand how linkage mechanisms enhance your machine's efficiency.

Table of Comparison

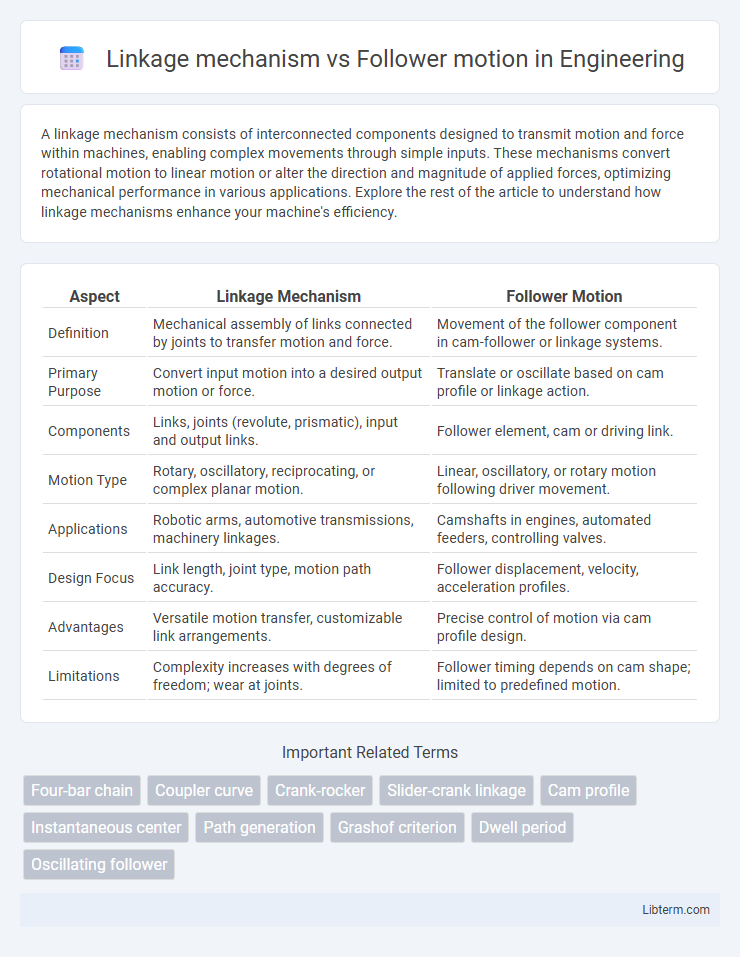

| Aspect | Linkage Mechanism | Follower Motion |

|---|---|---|

| Definition | Mechanical assembly of links connected by joints to transfer motion and force. | Movement of the follower component in cam-follower or linkage systems. |

| Primary Purpose | Convert input motion into a desired output motion or force. | Translate or oscillate based on cam profile or linkage action. |

| Components | Links, joints (revolute, prismatic), input and output links. | Follower element, cam or driving link. |

| Motion Type | Rotary, oscillatory, reciprocating, or complex planar motion. | Linear, oscillatory, or rotary motion following driver movement. |

| Applications | Robotic arms, automotive transmissions, machinery linkages. | Camshafts in engines, automated feeders, controlling valves. |

| Design Focus | Link length, joint type, motion path accuracy. | Follower displacement, velocity, acceleration profiles. |

| Advantages | Versatile motion transfer, customizable link arrangements. | Precise control of motion via cam profile design. |

| Limitations | Complexity increases with degrees of freedom; wear at joints. | Follower timing depends on cam shape; limited to predefined motion. |

Introduction to Linkage Mechanism and Follower Motion

Linkage mechanisms are assemblies of rigid bodies connected by joints to produce a specific output motion from a given input, fundamental in transforming rotary motion into desired paths. Follower motion refers to the movement of a specific point or component, known as the follower, which traces or follows a predetermined path generated by the linkage mechanism. Understanding the distinction between linkage mechanisms and follower motion is crucial for designing efficient mechanical systems in robotics, automation, and manufacturing processes.

Fundamental Concepts of Linkages

Linkage mechanisms consist of rigid bodies connected by joints to transfer motion and force through a defined path, enabling complex mechanical tasks. Follower motion refers to the specific movement of a point or link, often tracing a prescribed path controlled by the input link in the linkage system. Understanding the fundamental concepts of linkages involves analyzing degrees of freedom, types of joints (revolute, prismatic), and the kinematic chain to predict output motion from an input motion.

Types of Linkage Mechanisms

Linkage mechanisms encompass various types, including four-bar, slider-crank, and six-bar linkages, each designed to convert input motion into a specific output motion efficiently. Follower motion, a key concept in cam and linkage systems, refers to the type of movement exhibited by the follower, which can be oscillating, reciprocating, or rotating, depending on the linkage design. Understanding the types of linkage mechanisms enables precise control over the follower's motion, essential in machinery such as engines, automation equipment, and robotic arms.

Overview of Follower Motion

Follower motion in mechanical systems is the path or movement traced by a follower as it interacts with the cam or linkage mechanism, typically characterized as rotary, oscillatory, or reciprocating motion. The precision of follower motion directly influences the performance of automation and machinery, dictating speed, displacement, and force transmission. Understanding follower motion is essential for optimizing cam profiles, minimizing wear, and enhancing the efficiency of mechanical linkages.

Comparison: Linkage Geometry vs Follower Path

Linkage mechanisms rely on the precise geometry of interconnected components to produce controlled motion, defining the path based on pivot points and link lengths. In contrast, follower motion directly traces the desired path, often guided by a cam or track profile, prioritizing the trajectory of the follower over strict linkage constraints. Linkage geometry offers predictable movement dictated by fixed joints, whereas follower path allows more flexibility in motion design but requires careful shaping of the follower surface for accuracy.

Key Differences Between Linkages and Followers

Linkage mechanisms consist of multiple interconnected rigid bodies that transfer motion and force in a controlled path, while follower motion specifically refers to the movement of a part that traces or follows a given path. Linkages provide complex motion transformations such as converting rotary to linear movement, whereas followers typically exhibit simple reciprocating or oscillating motion. Key differences include the complexity of motion, number of components, and the role in mechanical systems, with linkages serving as the primary driver of motion and followers responding to guided paths.

Common Applications in Mechanical Systems

Linkage mechanisms and follower motion are fundamental in mechanical systems, where linkage mechanisms commonly enable precise, controlled movement in automotive suspensions and robotic arms due to their interconnected rigid links. Follower motion is essential in camshaft operations and automated assembly lines, translating rotary motion into linear or oscillating movements with high accuracy. Both are integral in manufacturing equipment, with linkage mechanisms often used for complex motion paths and follower motion providing consistent, repeatable actuation.

Design Considerations for Mechanisms

Linkage mechanisms require careful consideration of joint types, degrees of freedom, and material strength to ensure precise transmission of motion and force. Follower motion design emphasizes the path accuracy and stability, often necessitating the optimization of cam profiles and minimizing friction to achieve smooth, repeatable movement. Both mechanisms demand thorough kinematic analysis and stress evaluation to enhance durability and performance in their respective applications.

Advantages and Limitations of Each Motion Method

Linkage mechanisms offer precise motion control and durability, making them ideal for applications requiring repeated, exact movements, but they can be complex in design and limited by physical constraints like size and joint friction. Follower motion methods provide flexibility and easier adjustment for variable motion paths, yet they often suffer from reduced accuracy and increased wear due to continuous contact and sliding friction. Both methods serve critical roles in mechanical systems, with linkage mechanisms excelling in rigidity and follower motion favoring adaptability.

Future Trends in Mechanism Design

Future trends in mechanism design emphasize integrating smart materials and advanced sensors to enhance linkage mechanisms, enabling more precise and adaptive movements in robotic systems. Innovations in computational modeling and AI-driven optimization are improving the efficiency and versatility of follower motion designs, leading to smarter, real-time responsive mechanical systems. Emerging applications in aerospace, biomedical devices, and automation highlight the growing importance of hybrid mechanisms combining traditional linkages with electronic actuation for superior performance.

Linkage mechanism Infographic

libterm.com

libterm.com