Crack propagators are critical components in material science for understanding how fractures develop and spread under stress. They influence the durability and safety of structures by determining the rate and path of crack growth. Explore the rest of the article to discover how crack propagators affect your material's performance and longevity.

Table of Comparison

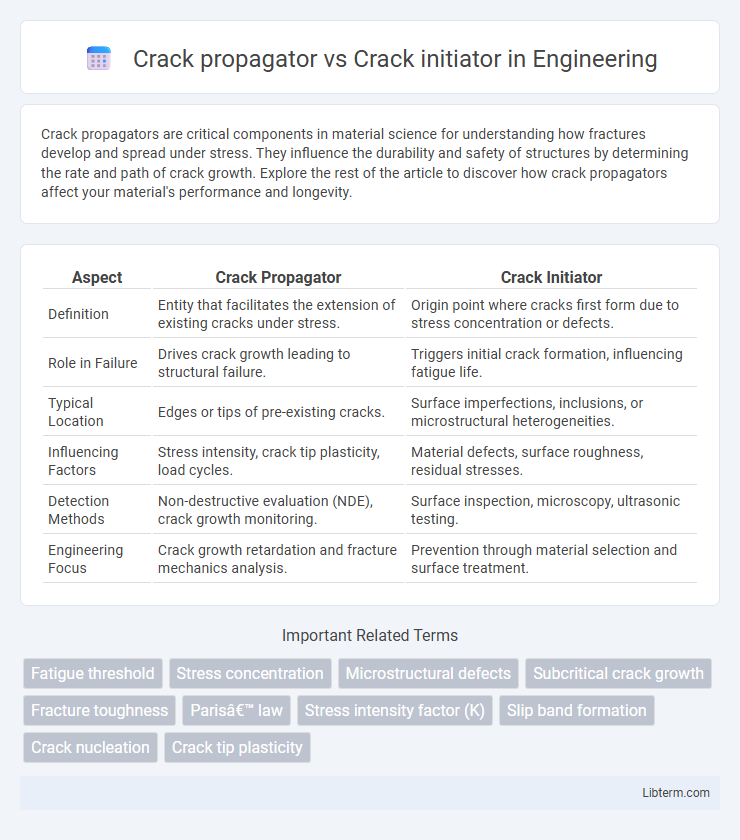

| Aspect | Crack Propagator | Crack Initiator |

|---|---|---|

| Definition | Entity that facilitates the extension of existing cracks under stress. | Origin point where cracks first form due to stress concentration or defects. |

| Role in Failure | Drives crack growth leading to structural failure. | Triggers initial crack formation, influencing fatigue life. |

| Typical Location | Edges or tips of pre-existing cracks. | Surface imperfections, inclusions, or microstructural heterogeneities. |

| Influencing Factors | Stress intensity, crack tip plasticity, load cycles. | Material defects, surface roughness, residual stresses. |

| Detection Methods | Non-destructive evaluation (NDE), crack growth monitoring. | Surface inspection, microscopy, ultrasonic testing. |

| Engineering Focus | Crack growth retardation and fracture mechanics analysis. | Prevention through material selection and surface treatment. |

Introduction to Crack Propagation and Initiation

Crack initiation refers to the process where microscopic flaws or stress concentrations develop into visible cracks, often influenced by material defects and cyclic loading conditions. Crack propagation is the subsequent growth of these cracks under sustained stress, driven by factors such as stress intensity factor (K), fracture toughness (K_IC), and environmental conditions like corrosion or temperature. Understanding the distinction between crack initiators and propagators is crucial for predicting component lifespan and implementing effective fracture mechanics-based maintenance strategies.

Defining Crack Initiators: The Starting Point

Crack initiators are microstructural defects or stress concentrators where cracks first form, typically caused by factors like surface scratches, corrosion pits, or inclusions in the material. These initiation sites experience localized stress that exceeds the material's strength, leading to nucleation of a crack. Understanding the nature and location of crack initiators is critical for predicting fatigue life and preventing structural failure in engineering components.

Understanding Crack Propagators: Growth and Extension

Crack propagators are responsible for the growth and extension of existing fractures under cyclic or sustained loading, playing a critical role in material failure. Unlike crack initiators, which cause the formation of initial micro-cracks often triggered by stress concentrators or material defects, propagators drive the progressive lengthening of these cracks through mechanisms like fatigue or stress corrosion. Understanding crack propagation involves studying the stress intensity factors, crack tip plasticity, and environmental influences that accelerate crack growth and eventual structural failure.

Key Differences: Crack Initiators vs Crack Propagators

Crack initiators are microscopic flaws or stress concentrators such as inclusions, voids, or surface scratches where cracks begin, while crack propagators are the mechanisms and factors that drive the growing crack through the material, including cyclic loading and material fatigue. Key differences lie in their roles: initiators trigger the initial fracture, often at stress risers or defects, whereas propagators facilitate crack growth through processes like plastic deformation and microstructural fatigue. Understanding the distinction aids in improving material design, focusing on flaw detection to prevent initiation and enhancing toughness to retard propagation.

Material Properties Influencing Crack Behavior

Crack initiators are often influenced by material properties such as microstructural defects, grain boundaries, and inclusions that serve as stress concentration points promoting crack nucleation. Crack propagators depend heavily on mechanical properties like fracture toughness, yield strength, and residual stress, which dictate the crack growth rate and resistance to propagation. Understanding the interplay between hardness, ductility, and environmental factors is essential for predicting crack behavior in engineering materials.

Common Sources of Crack Initiators in Engineering

Common sources of crack initiators in engineering include material defects such as inclusions and voids, surface damage like scratches and corrosion, and stress concentrators such as notches or sharp corners. Crack initiators often arise at microscopic levels where stress exceeds the material's local strength, leading to the formation of microcracks. Effective identification and control of these initiation sites are critical for enhancing fatigue life and preventing premature failure in structural components.

Mechanisms Driving Crack Propagation

Crack propagators advance existing cracks through mechanisms like stress concentration at the crack tip, resulting in plastic deformation and microstructural changes that facilitate crack growth. Factors such as cyclic loading, environmental corrosion, and material fatigue accelerate crack propagation by repeatedly weakening atomic bonds along the crack front. Unlike crack initiators, which are typically defects or stress risers where cracks originate, crack propagators dominate the fracture process by governing the rate and direction of crack extension within the material.

Detection and Analysis Techniques

Crack initiators are typically identified through microscopic examination methods such as scanning electron microscopy (SEM) and surface profilometry, which detect early-stage microstructural flaws or stress concentrators responsible for the onset of cracking. Crack propagators require advanced non-destructive evaluation (NDE) techniques like ultrasonic testing, acoustic emission monitoring, and digital image correlation to analyze the growth patterns and rate of crack extension under cyclic loads. Combining fractographic analysis with computational fracture mechanics models enhances accuracy in distinguishing initiation sites from propagation zones for effective failure prevention and maintenance planning.

Mitigation Strategies for Crack Initiation and Propagation

Mitigation strategies for crack initiation emphasize material selection with high fatigue resistance, surface treatments such as shot peening to induce compressive stresses, and controlling stress concentrations through design optimization. For crack propagation, techniques include applying crack arresters, using fracture toughness-enhancing materials, and employing regular non-destructive inspections to detect and repair cracks before catastrophic failure. Implementing these strategies reduces the likelihood of crack development and extension, improving structural integrity and lifespan.

Real-World Applications and Case Studies

Crack initiators are often microscopic defects such as inclusions, corrosion pits, or manufacturing flaws where stress concentration triggers initial crack formation in materials like metals and composites. Crack propagators refer to existing cracks that grow under cyclic loading or fatigue, leading to significant structural failure in engineering components such as aircraft wings, bridges, and pressure vessels. Real-world case studies from aerospace and civil infrastructure highlight how early detection of crack initiators combined with monitoring crack propagation rates can prevent catastrophic failures and extend service life.

Crack propagator Infographic

libterm.com

libterm.com