A tower crane is an essential piece of equipment in construction, designed to lift and move heavy materials with precision and height advantage. Its tall structure and rotating jib allow for efficient handling of loads in tight urban spaces. Discover how choosing the right tower crane can enhance your project's efficiency and safety in the full article.

Table of Comparison

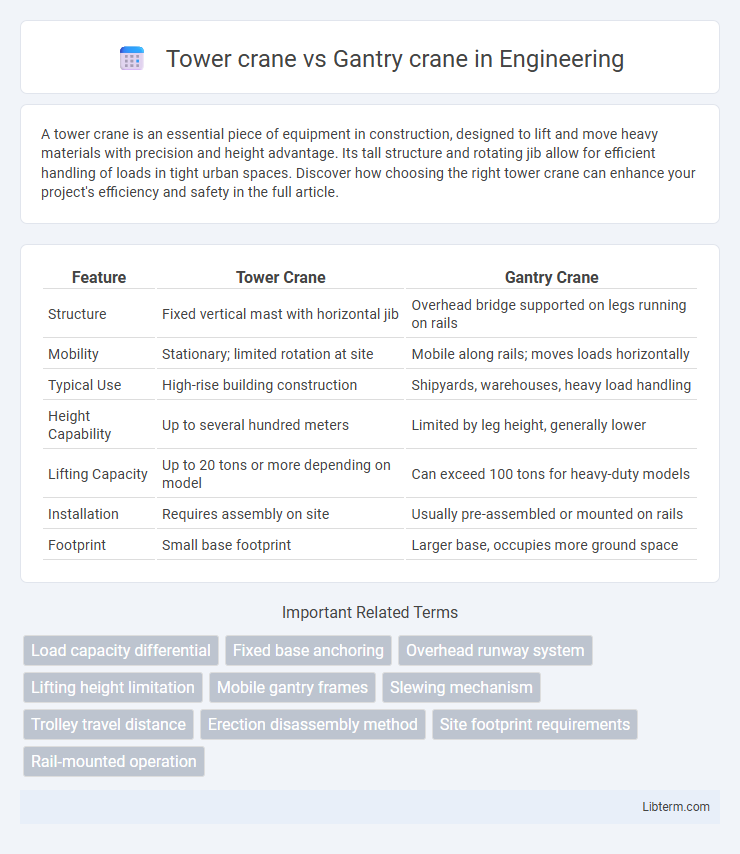

| Feature | Tower Crane | Gantry Crane |

|---|---|---|

| Structure | Fixed vertical mast with horizontal jib | Overhead bridge supported on legs running on rails |

| Mobility | Stationary; limited rotation at site | Mobile along rails; moves loads horizontally |

| Typical Use | High-rise building construction | Shipyards, warehouses, heavy load handling |

| Height Capability | Up to several hundred meters | Limited by leg height, generally lower |

| Lifting Capacity | Up to 20 tons or more depending on model | Can exceed 100 tons for heavy-duty models |

| Installation | Requires assembly on site | Usually pre-assembled or mounted on rails |

| Footprint | Small base footprint | Larger base, occupies more ground space |

Introduction: Understanding Tower Cranes and Gantry Cranes

Tower cranes are fixed cranes commonly used in the construction of tall buildings, featuring a vertical mast and a horizontal jib to lift heavy materials to great heights. Gantry cranes consist of a bridge supported by two or more legs that move on wheels or rails, primarily utilized for loading, unloading, and transporting heavy objects in shipyards, factories, and warehouses. Both cranes are essential for handling heavy loads but differ significantly in mobility, structure, and typical applications.

Core Differences Between Tower Cranes and Gantry Cranes

Tower cranes are fixed to the ground or a building structure, providing vertical and horizontal movement primarily for high-rise construction, while gantry cranes are mobile and travel on rails, ideal for lifting heavy loads in shipyards and warehouses. Tower cranes have a tall mast and a horizontal jib, enabling them to reach significant heights and cover wide areas, whereas gantry cranes consist of a bridge supported by two legs that span a workspace. The core differences lie in their mobility, structure, and operational applications, with tower cranes excelling in vertical reach and gantry cranes in horizontal load transport across large surfaces.

Structural Design Comparison

Tower cranes feature a vertical mast and a horizontal jib, designed for high-rise construction with a compact footprint and significant height reach, optimizing load distribution through a fixed base anchored to the ground. Gantry cranes utilize a bridge-like structure supported by two legs that move on rails, providing flexibility in lifting heavy loads over wide spans but with limited height compared to tower cranes. Structural design of tower cranes prioritizes vertical stability and resistance to wind loads, whereas gantry cranes emphasize horizontal mobility and load capacity for large workspace coverage.

Typical Applications and Industries

Tower cranes dominate construction sites, particularly for high-rise buildings and large infrastructure projects, due to their ability to lift heavy loads to great heights with precision. Gantry cranes excel in shipyards, rail yards, and manufacturing plants where heavy materials must be moved horizontally over large areas, especially for loading and unloading cargo or assembling large components. Industries such as construction, shipping, manufacturing, and logistics rely heavily on tower cranes for vertical lifting and gantry cranes for heavy-duty horizontal transport.

Load Capacity and Lifting Range

Tower cranes typically offer higher load capacities ranging from 10 to 20 tons and boast extensive lifting ranges vertically up to 265 feet and horizontally spanning over 230 feet. Gantry cranes, while generally supporting heavier loads between 20 to 100 tons, have more limited horizontal travel but excel in lifting heavy materials at industrial sites or shipyards. The choice between tower and gantry cranes depends on the specific lifting range requirements and load capacities needed for construction or manufacturing projects.

Mobility and Installation Requirements

Tower cranes offer limited mobility as they are typically fixed to the ground or attached to structures, requiring extensive foundation work and assembly with cranes and heavy equipment. Gantry cranes provide greater mobility, often equipped with wheels or rails allowing them to move along predefined paths, and their installation usually involves less groundwork and faster setup. The choice between the two depends on site conditions and the need for flexibility in crane movement.

Advantages of Tower Cranes

Tower cranes offer significant height advantages, allowing them to reach and lift materials to greater elevations in construction projects compared to gantry cranes. Their compact footprint and ability to rotate 360 degrees provide exceptional maneuverability and precision in dense urban sites. Tower cranes also excel in lifting heavy loads with high stability, making them ideal for tall building construction and infrastructure projects where vertical reach and load capacity are critical.

Advantages of Gantry Cranes

Gantry cranes offer superior versatility in load handling due to their mobile framework, enabling easy movement across various work sites and supporting heavy-duty lifting operations in shipyards and construction areas. They require less structural support compared to tower cranes, allowing installation in locations with space constraints and reducing overall setup costs. Gantry cranes also provide greater flexibility in lifting capacity and span adjustments, making them ideal for handling oversized or unusually shaped loads efficiently.

Safety Considerations for Each Type

Tower cranes require rigorous safety measures including proper foundation and anchoring to prevent tipping, as well as regular inspections of hoist ropes and counterweights due to their height and load capacity. Gantry cranes emphasize safety through stable rail tracks, adequate operator training for horizontal movement control, and load monitoring systems to avoid overloading during heavy lifting. Both crane types demand adherence to strict maintenance schedules and compliance with OSHA safety standards to minimize operational hazards.

Choosing the Right Crane for Your Project

Selecting the right crane involves evaluating factors such as load capacity, site layout, and project duration. Tower cranes excel in vertical lifting and are ideal for tall building construction with limited ground space, while gantry cranes offer superior horizontal mobility for heavy loads in shipyards or industrial yards. Considering project-specific requirements ensures optimal crane performance, safety, and cost-efficiency.

Tower crane Infographic

libterm.com

libterm.com