A corner joint is a fundamental woodworking or metalworking technique used to connect two pieces at a right angle, providing structural strength and stability. Different types of corner joints, such as butt joints, miter joints, and box joints, offer varying levels of durability and aesthetic appeal depending on the project requirements. Explore the rest of the article to discover the best corner joint options for your next build.

Table of Comparison

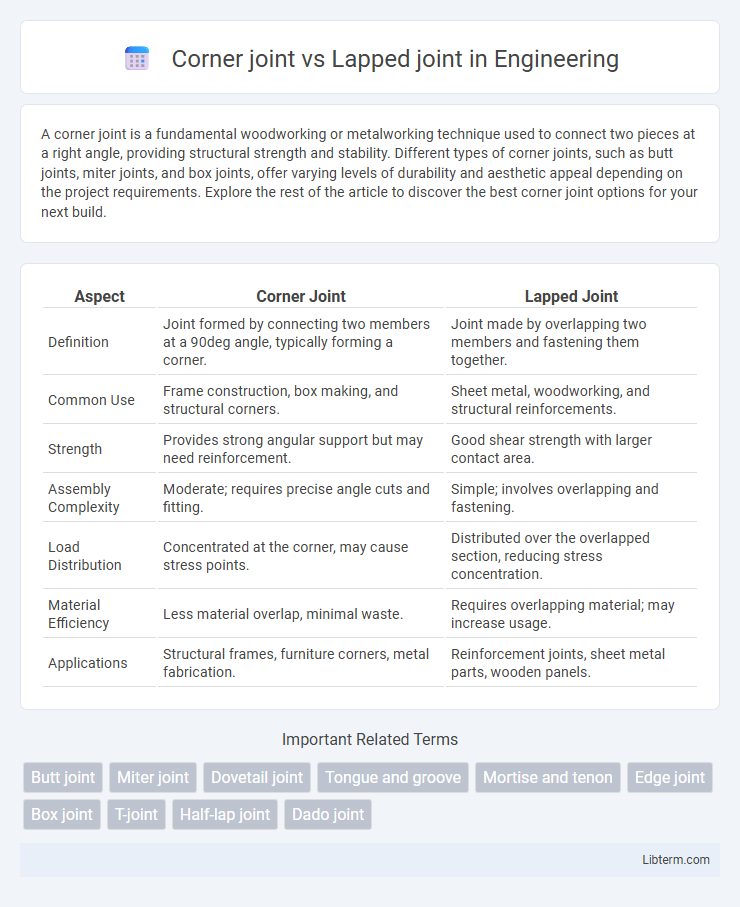

| Aspect | Corner Joint | Lapped Joint |

|---|---|---|

| Definition | Joint formed by connecting two members at a 90deg angle, typically forming a corner. | Joint made by overlapping two members and fastening them together. |

| Common Use | Frame construction, box making, and structural corners. | Sheet metal, woodworking, and structural reinforcements. |

| Strength | Provides strong angular support but may need reinforcement. | Good shear strength with larger contact area. |

| Assembly Complexity | Moderate; requires precise angle cuts and fitting. | Simple; involves overlapping and fastening. |

| Load Distribution | Concentrated at the corner, may cause stress points. | Distributed over the overlapped section, reducing stress concentration. |

| Material Efficiency | Less material overlap, minimal waste. | Requires overlapping material; may increase usage. |

| Applications | Structural frames, furniture corners, metal fabrication. | Reinforcement joints, sheet metal parts, wooden panels. |

Understanding Corner Joints

Corner joints create a strong connection by joining two pieces of material at a right angle, commonly used in frames and box construction to provide stability and precise alignment. They often involve techniques like mitering or using reinforcing elements such as dowels, biscuits, or nails to enhance joint strength and durability. Understanding corner joints is essential for woodworking and metalworking projects where structural integrity and clean aesthetics are critical.

What is a Lapped Joint?

A lapped joint is a woodworking or metalworking technique where two pieces overlap each other and are fastened together, providing increased surface area for adhesive or mechanical fastening. It is commonly used for joining materials at right angles or in parallel, resulting in a strong and stable connection. Unlike corner joints, lapped joints distribute stress over a larger area, enhancing durability in structural applications.

Structural Strength Comparison

Corner joints provide strong connections primarily in frame constructions where forces are applied perpendicularly, allowing effective load distribution along both adjoining members. Lapped joints offer increased surface area for adhesive or fastener bonding, resulting in superior tensile and shear strength, especially in applications requiring resistance to pulling forces. Comparative studies show lapped joints typically outperform corner joints in overall structural strength due to enhanced overlap and load transfer capabilities.

Applications of Corner Joints

Corner joints are commonly used in woodworking and metalworking to create frames, boxes, and furniture due to their ability to provide strong right-angle connections. These joints are essential in constructing cabinets, door frames, and picture frames where stability and aesthetic appeal are important. The design of corner joints allows for easy assembly and alignment, making them ideal for projects requiring precise 90-degree angles.

Uses of Lapped Joints

Lapped joints are widely used in woodworking and metalworking for their strength and ease of assembly, especially in frame construction, cabinetry, and furniture making. Their overlapping surfaces provide increased bonding area, making them ideal for applications requiring enhanced load distribution and resistance to shear forces. Common uses include joining thin materials, creating long beams, and fabricating metal structures where durability and alignment are crucial.

Advantages of Corner Joints

Corner joints provide excellent structural integrity by distributing stress evenly across connected surfaces, enhancing the durability of frames and boxes. They allow for clean, aesthetically pleasing right-angle connections that simplify assembly and reduce material waste. These joints are particularly effective in woodworking and metal fabrication, offering strong support in load-bearing applications while maintaining a minimalist visual profile.

Benefits of Lapped Joints

Lapped joints offer increased surface area for adhesive or mechanical fastening, resulting in stronger and more durable connections compared to corner joints. They distribute stress more evenly, reducing the risk of joint failure under load or vibration. Commonly used in woodworking and metalworking, lapped joints enhance structural integrity and alignment in frames, panels, and assemblies.

Limitations of Corner Joints

Corner joints often suffer from limited mechanical strength, especially under tensile and shear stresses, making them less suitable for load-bearing applications. The alignment of mating surfaces in corner joints can also cause difficulties in achieving a flush finish, leading to potential gaps and reduced aesthetic appeal. Furthermore, corner joints are more susceptible to movement and distortion over time due to uneven stress distribution and wood expansion.

Limitations of Lapped Joints

Lapped joints often face limitations such as reduced strength compared to corner joints due to stress concentration at the overlap region. These joints are prone to misalignment and require precise surface preparation to ensure proper bonding. Additionally, lapped joints can cause increased material thickness, leading to difficulties in assembly and potential interference in design applications.

Choosing the Right Joint for Your Project

Choosing the right joint for your project depends on the structural requirements and aesthetic preferences. Corner joints provide a strong 90-degree connection ideal for frames and boxes, offering enhanced stability in load-bearing applications. Lapped joints overlap two pieces, creating increased surface area for adhesive or fastener contact, making them suitable for projects requiring moderate strength with a cleaner appearance.

Corner joint Infographic

libterm.com

libterm.com