The modulus of rigidity, also known as the shear modulus, measures a material's ability to resist shear deformation under applied force. This property is crucial in determining how materials behave in mechanical and structural applications where forces cause twisting or sliding. Explore the rest of this article to understand how the modulus of rigidity influences material selection and design.

Table of Comparison

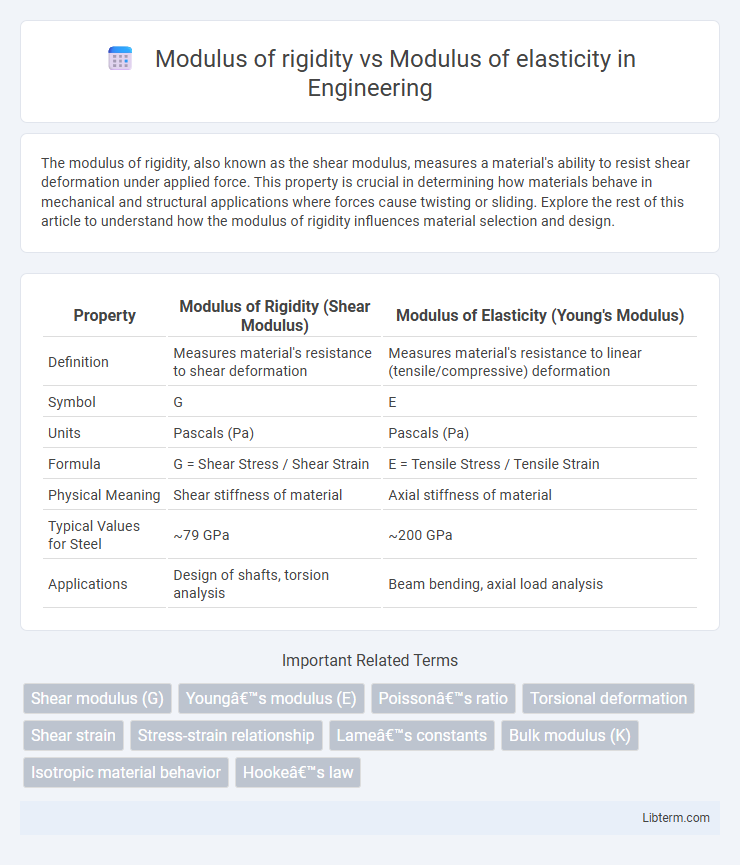

| Property | Modulus of Rigidity (Shear Modulus) | Modulus of Elasticity (Young's Modulus) |

|---|---|---|

| Definition | Measures material's resistance to shear deformation | Measures material's resistance to linear (tensile/compressive) deformation |

| Symbol | G | E |

| Units | Pascals (Pa) | Pascals (Pa) |

| Formula | G = Shear Stress / Shear Strain | E = Tensile Stress / Tensile Strain |

| Physical Meaning | Shear stiffness of material | Axial stiffness of material |

| Typical Values for Steel | ~79 GPa | ~200 GPa |

| Applications | Design of shafts, torsion analysis | Beam bending, axial load analysis |

Introduction to Modulus of Rigidity and Modulus of Elasticity

Modulus of rigidity, also known as shear modulus, measures a material's resistance to shear deformation, quantifying how it responds to tangential forces. Modulus of elasticity, or Young's modulus, represents a material's ability to withstand changes in length when subjected to axial stress, indicating stiffness under tensile or compressive loads. Both moduli are fundamental mechanical properties essential for analyzing stress-strain relationships and predicting material behavior in structural and mechanical engineering applications.

Defining Modulus of Rigidity (Shear Modulus)

Modulus of rigidity, also known as the shear modulus, measures a material's response to shear stress, quantifying its ability to resist shape changes without volume alteration. It is defined as the ratio of shear stress to the corresponding shear strain within the elastic limit of the material. Unlike modulus of elasticity, which relates to tensile or compressive stress and strain, modulus of rigidity specifically addresses deformation due to tangential forces.

Understanding Modulus of Elasticity (Young’s Modulus)

Modulus of Elasticity, or Young's Modulus, measures a material's ability to resist deformation under tensile stress by quantifying the ratio of stress to strain within the elastic limit. It is a fundamental property that indicates stiffness, defined as the slope of the linear portion of the stress-strain curve for materials like steel, aluminum, and rubber. Unlike the Modulus of Rigidity, which relates to shear deformation, Young's Modulus specifically describes axial elasticity, playing a crucial role in structural engineering and materials science.

Fundamental Differences Between the Two Moduli

Modulus of rigidity, also known as shear modulus, measures a material's response to shear stress, describing its ability to resist shape changes without volume alteration. In contrast, modulus of elasticity, or Young's modulus, quantifies the resistance to linear deformation under tensile or compressive stress, reflecting changes in length. Fundamental differences include the direction of applied force--shear versus axial--and the deformation type, crucial for material selection in engineering applications.

Mathematical Expressions and Units

The modulus of rigidity (shear modulus, G) is mathematically expressed as G = t/g, where t is shear stress and g is shear strain, with units of pascals (Pa). The modulus of elasticity (Young's modulus, E) follows E = s/e, where s is normal stress and e is normal strain, also measured in pascals (Pa). Both moduli quantify material stiffness but apply to different deformation types, with the modulus of elasticity relating to tensile or compressive stress and the modulus of rigidity relating to shear stress.

Physical Significance and Applications

Modulus of rigidity, also known as shear modulus, measures a material's resistance to shear deformation under applied shear stress, reflecting its ability to withstand shape changes without volume alteration. Modulus of elasticity, or Young's modulus, quantifies the material's stiffness by relating tensile or compressive stress to longitudinal strain, indicating how much it will stretch or compress under load. Modulus of rigidity is crucial in applications involving torsion and shear forces such as shafts and beams, while modulus of elasticity is essential for structural analysis, determining deflections and stresses in load-bearing components like bridges and buildings.

Role in Material Selection and Engineering Design

Modulus of rigidity measures a material's resistance to shear deformation, making it crucial for components subjected to twisting or torsional stresses, while modulus of elasticity quantifies stiffness under tensile or compressive loads, guiding designs requiring minimal elastic deformation. Engineers select materials with appropriate modulus values to ensure structural integrity, optimize performance, and prevent failure in applications like shafts, beams, and springs. Balancing both moduli is essential for accurate stress analysis and achieving desired mechanical behavior in complex load conditions.

Factors Affecting Modulus of Rigidity and Elasticity

Modulus of rigidity, also known as shear modulus, depends primarily on the material's internal atomic structure and temperature, with higher temperatures typically reducing its value due to increased atomic vibrations. Modulus of elasticity, or Young's modulus, is influenced by factors such as material composition, crystalline structure, and defects, while temperature and strain rate can also significantly affect its magnitude. Both moduli are intrinsic properties that reflect different deformation responses--shear and tensile--and vary based on microstructural characteristics and environmental conditions.

Experimental Determination Methods

The modulus of rigidity, or shear modulus, is experimentally determined using torsion tests on cylindrical specimens, measuring the angular deformation under applied torque. The modulus of elasticity, or Young's modulus, is typically obtained through uniaxial tensile tests, where longitudinal strain is measured in response to axial stress. Both methods require precise instrumentation such as strain gauges or extensometers to accurately capture deformation and calculate the respective moduli from stress-strain relationships.

Summary: Choosing Between Modulus of Rigidity and Elasticity

Modulus of rigidity measures a material's resistance to shear deformation, critical for applications involving torsion and shear stress, while modulus of elasticity quantifies stiffness under tensile or compressive loads, essential for understanding linear elastic behavior. Selecting between the two depends on the type of stress and deformation expected in the engineering design; torsional components require focus on modulus of rigidity, whereas axial loading scenarios prioritize modulus of elasticity. Accurate material specification hinges on applying the correct modulus to predict structural response and ensure safety and performance.

Modulus of rigidity Infographic

libterm.com

libterm.com