Mean Time to Repair (MTTR) measures the average time required to diagnose and fix a failure in a system, reflecting efficiency in maintenance processes. Lower MTTR indicates faster recovery and improved system uptime, which directly impacts your operational productivity and cost savings. Explore the rest of the article to learn how optimizing MTTR can enhance your maintenance strategy and equipment reliability.

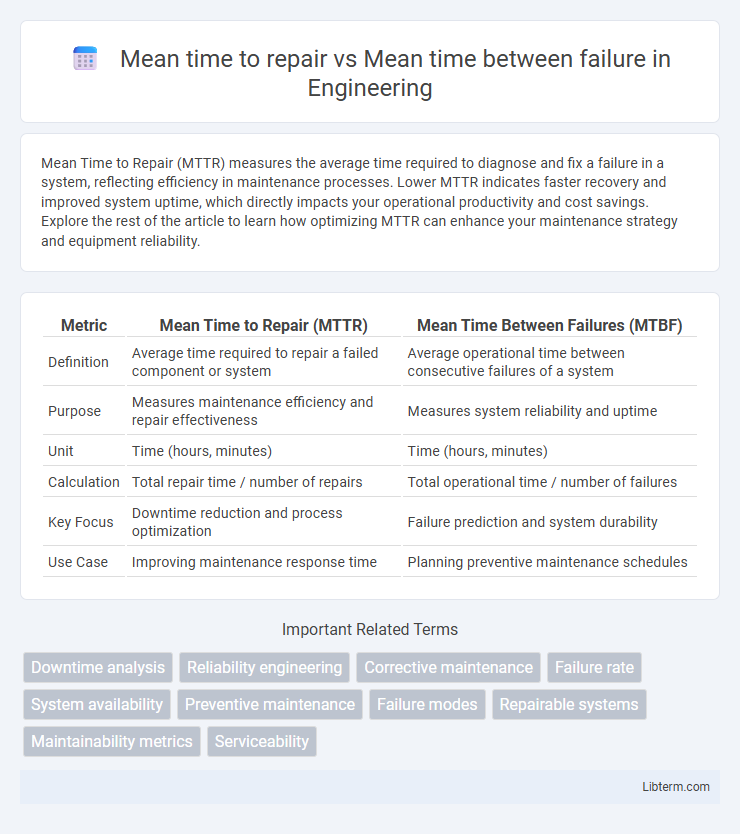

Table of Comparison

| Metric | Mean Time to Repair (MTTR) | Mean Time Between Failures (MTBF) |

|---|---|---|

| Definition | Average time required to repair a failed component or system | Average operational time between consecutive failures of a system |

| Purpose | Measures maintenance efficiency and repair effectiveness | Measures system reliability and uptime |

| Unit | Time (hours, minutes) | Time (hours, minutes) |

| Calculation | Total repair time / number of repairs | Total operational time / number of failures |

| Key Focus | Downtime reduction and process optimization | Failure prediction and system durability |

| Use Case | Improving maintenance response time | Planning preventive maintenance schedules |

Introduction to MTTR and MTBF

Mean Time to Repair (MTTR) measures the average time required to repair a failed component or system and restore it to full functionality. Mean Time Between Failure (MTBF) calculates the average time elapsed between consecutive failures in a system during operation. Both MTTR and MTBF are critical metrics in reliability engineering for optimizing maintenance strategies and improving system uptime.

Defining Mean Time to Repair (MTTR)

Mean Time to Repair (MTTR) quantifies the average duration required to diagnose, repair, and restore a system or component to its operational state after a failure occurs. It is a critical metric in maintenance management that directly impacts system availability and operational efficiency. MTTR differs from Mean Time Between Failures (MTBF), which measures the average time between inherent failures, focusing on reliability rather than repair efficiency.

Understanding Mean Time Between Failures (MTBF)

Mean Time Between Failures (MTBF) quantifies the average operational time between inherent failures of a system during normal use, serving as a critical metric for assessing system reliability. MTBF is calculated by dividing the total operational time by the number of failures, guiding maintenance schedules and predicting system longevity. Understanding MTBF helps optimize preventive maintenance strategies, minimize system downtime, and improve overall equipment effectiveness (OEE).

Key Differences Between MTTR and MTBF

Mean Time to Repair (MTTR) measures the average time required to fix a system or component after a failure, focusing on maintenance efficiency and downtime reduction. Mean Time Between Failures (MTBF) calculates the average operational time between consecutive failures, emphasizing system reliability and lifespan prediction. The key difference lies in MTTR addressing repair duration, while MTBF centers on failure frequency and reliability assessment.

Importance of MTTR and MTBF in Reliability Engineering

Mean Time to Repair (MTTR) and Mean Time Between Failure (MTBF) are critical metrics in reliability engineering used to measure system performance and downtime. MTTR quantifies the average repair duration after a failure, directly impacting system availability and maintenance efficiency, while MTBF estimates the average operational time between failures, indicating system reliability. Optimizing both MTTR and MTBF enhances overall equipment effectiveness, reduces maintenance costs, and improves operational uptime in industrial environments.

How to Calculate MTTR and MTBF

Mean Time to Repair (MTTR) is calculated by dividing the total downtime by the number of repairs performed, reflecting the average time required to restore a system after failure. Mean Time Between Failures (MTBF) is determined by dividing the total operational time by the number of failures, indicating the average time a system operates without interruption. Accurate calculation of MTTR and MTBF involves collecting detailed failure and repair records to improve maintenance strategies and enhance system reliability metrics.

Factors Influencing MTTR and MTBF Values

Mean Time to Repair (MTTR) and Mean Time Between Failure (MTBF) are influenced by factors such as equipment complexity, maintenance procedures, and environmental conditions. High-quality components and proactive maintenance strategies typically increase MTBF by reducing failure frequency, while efficient repair teams and accessible spare parts lower MTTR by minimizing downtime. Operational stress and usage patterns also significantly affect both metrics, with harsher environments decreasing MTBF and complicating repairs, thus increasing MTTR.

Role of MTTR and MTBF in Preventive Maintenance

Mean Time to Repair (MTTR) and Mean Time Between Failure (MTBF) are critical metrics in preventive maintenance strategies, where MTTR measures the average time required to fix equipment after a breakdown, and MTBF quantifies the average operational time between failures. Optimizing MTBF extends equipment uptime by identifying failure patterns, while minimizing MTTR reduces downtime through efficient repair processes, directly enhancing maintenance scheduling and resource allocation. Leveraging precise MTTR and MTBF data enables predictive maintenance, reducing unexpected failures and improving overall asset reliability.

Strategies to Improve MTTR and MTBF

Effective strategies to improve Mean Time to Repair (MTTR) involve implementing predictive maintenance through real-time monitoring systems and providing specialized training to maintenance teams for faster diagnostics and repairs. Enhancing Mean Time Between Failure (MTBF) requires using high-quality components, applying root cause analysis for failure prevention, and optimizing equipment design and operating conditions. Combining data analytics with preventive maintenance schedules significantly increases system reliability and operational efficiency.

MTTR vs MTBF: Which Metric Matters Most?

MTTR (Mean Time to Repair) measures the average time required to fix a system after a failure, indicating maintenance efficiency and downtime impact. MTBF (Mean Time Between Failure) calculates the average operational time between breakdowns, reflecting system reliability and performance stability. Prioritizing MTBF helps improve product design and reduce failures, while emphasizing MTTR enhances repair processes and minimizes service interruptions; organizations must balance both metrics based on operational priorities and maintenance strategies.

Mean time to repair Infographic

libterm.com

libterm.com