Corner welds are essential for joining two metal pieces at a right angle, providing strong and durable seams in various structural applications. Proper technique and welding parameters ensure optimal penetration and minimal defects, resulting in enhanced joint performance. Discover the key methods and tips to perfect your corner weld in the rest of this article.

Table of Comparison

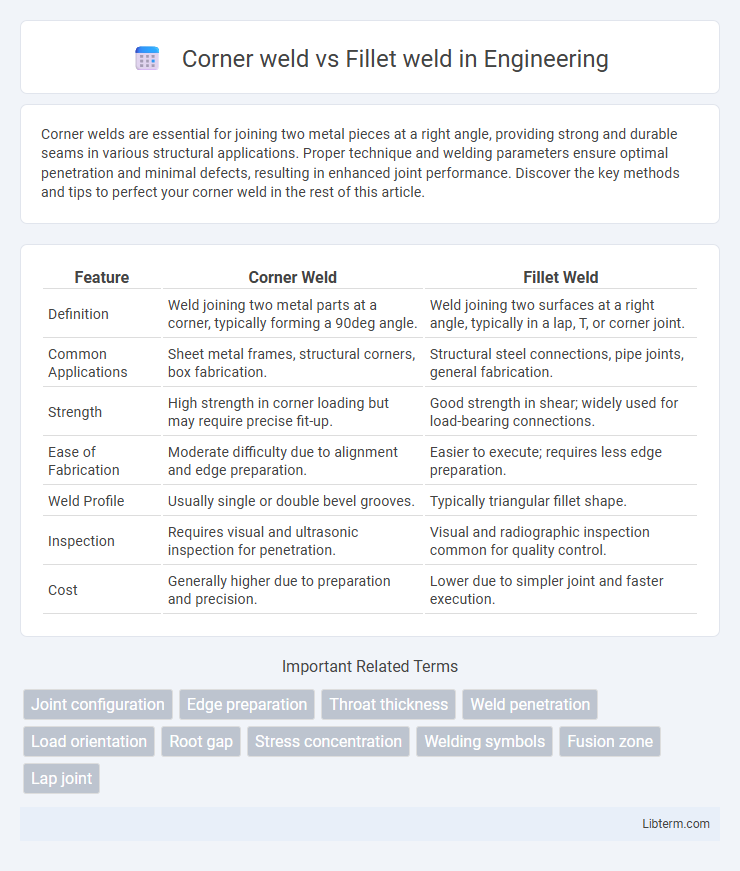

| Feature | Corner Weld | Fillet Weld |

|---|---|---|

| Definition | Weld joining two metal parts at a corner, typically forming a 90deg angle. | Weld joining two surfaces at a right angle, typically in a lap, T, or corner joint. |

| Common Applications | Sheet metal frames, structural corners, box fabrication. | Structural steel connections, pipe joints, general fabrication. |

| Strength | High strength in corner loading but may require precise fit-up. | Good strength in shear; widely used for load-bearing connections. |

| Ease of Fabrication | Moderate difficulty due to alignment and edge preparation. | Easier to execute; requires less edge preparation. |

| Weld Profile | Usually single or double bevel grooves. | Typically triangular fillet shape. |

| Inspection | Requires visual and ultrasonic inspection for penetration. | Visual and radiographic inspection common for quality control. |

| Cost | Generally higher due to preparation and precision. | Lower due to simpler joint and faster execution. |

Introduction to Corner Welds and Fillet Welds

Corner welds join two metal pieces at a perpendicular or near-perpendicular angle, creating a strong joint by fusing edges along the corner of the components. Fillet welds commonly form triangular cross-sections and are used to reinforce T-joints, lap joints, and corner joints by filling the junction between two surfaces. Both types are essential in structural fabrication, offering reliability and strength in metal assemblies across automotive, construction, and manufacturing industries.

Definitions: What is a Corner Weld?

A corner weld joins two metal pieces at a right angle, typically forming an L-shaped joint. This weld is used to connect plates or sections at their edges, creating a strong external corner with proper penetration and fusion. Corner welds are essential in fabricating frames, boxes, and structural assemblies where perpendicular attachment is required.

Definitions: What is a Fillet Weld?

A fillet weld is a triangular cross-section weld used to join two metal pieces at a right angle or lap joint without groove preparation. It is commonly applied in T-joints, lap joints, and corner joints to provide strength and support by filling the intersection between the workpieces. Fillet welds are characterized by their leg length and throat thickness, which determine the weld's strength and load-carrying capacity.

Key Differences Between Corner Welds and Fillet Welds

Corner welds join two metal pieces at a right angle, typically forming an L-shaped joint, while fillet welds are triangular welds used to join two surfaces at approximately right angles without the need for groove preparation. Fillet welds are commonly applied on lap, T, and corner joints, offering versatility in various structural applications, whereas corner welds are specifically designed for edges and external corners. The key differences lie in their joint configuration, weld shape, and typical use cases in metal fabrication and construction.

Application Areas for Corner Welds

Corner welds are primarily used in the fabrication of box-like structures, frames, and enclosures where two metal pieces meet at a right angle. These welds provide strong joint integrity in applications such as sheet metal work, HVAC duct systems, and architectural metal frameworks. Their ability to create a sealed joint makes corner welds ideal for containers and pressure vessels requiring leak-tight construction.

Application Areas for Fillet Welds

Fillet welds are widely used in structural steel fabrication, shipbuilding, and automotive industries due to their ability to join perpendicular or angled surfaces efficiently. These welds provide strong, reliable connections for T-joints, lap joints, and corner joints, making them ideal for frameworks, machinery, and construction applications. Their versatility and ease of application make fillet welds a preferred choice for load-bearing and non-load-bearing assemblies.

Strength and Performance Comparison

Corner welds provide strong joint integrity in applications involving perpendicular metal components, offering high resistance to shear and tensile forces due to the direct alignment of weld metal along the joint interface. Fillet welds, commonly used for lap, T, and corner joints, balance strength and ease of fabrication by distributing stress over a larger area, but generally exhibit lower tensile strength compared to full-penetration corner welds. Performance-wise, corner welds are preferred for load-bearing structures requiring maximum joint strength, while fillet welds offer versatility and sufficient strength for moderate load conditions and simpler assembly.

Advantages and Disadvantages of Corner Welds

Corner welds provide a clean, aesthetically pleasing joint ideal for frame and box construction, offering good resistance to bending forces. They allow for easier assembly and alignment of parts compared to fillet welds but may require more precise fit-up and can be less effective under heavy tensile loads. Limited throat thickness in corner welds can reduce overall strength, making them less suitable for high-stress applications compared to fillet welds.

Advantages and Disadvantages of Fillet Welds

Fillet welds offer advantages such as easier preparation, faster welding speed, and adaptability to various joint types without the need for edge machining, resulting in cost-effective fabrication. However, disadvantages include lower tensile strength compared to groove welds, potential for incomplete fusion in improper execution, and difficulty in inspecting internal weld quality. Choosing fillet welds suits applications requiring robust, economical joining on lap, T, or corner joints where deep penetration is less critical.

Choosing the Right Weld for Your Project

Selecting the appropriate weld type depends on factors such as joint design, load requirements, and material thickness; corner welds are ideal for perpendicular joints that require strong, clean edges, while fillet welds are commonly used for lap, tee, and corner joints where rapid, versatile welding is needed. Corner welds provide greater structural integrity for components subject to directional stress, whereas fillet welds offer easier access and faster application, especially in confined spaces or complex assemblies. Evaluating project-specific stress, accessibility, and aesthetic considerations ensures optimal weld performance and longevity.

Corner weld Infographic

libterm.com

libterm.com