Selective laser sintering (SLS) is an advanced additive manufacturing technique that uses a high-powered laser to fuse powdered materials into solid, three-dimensional objects layer by layer. This process allows for the creation of complex geometries with high precision and mechanical strength, making it ideal for prototyping and small-batch production. Explore the rest of the article to discover how SLS technology can transform your manufacturing projects.

Table of Comparison

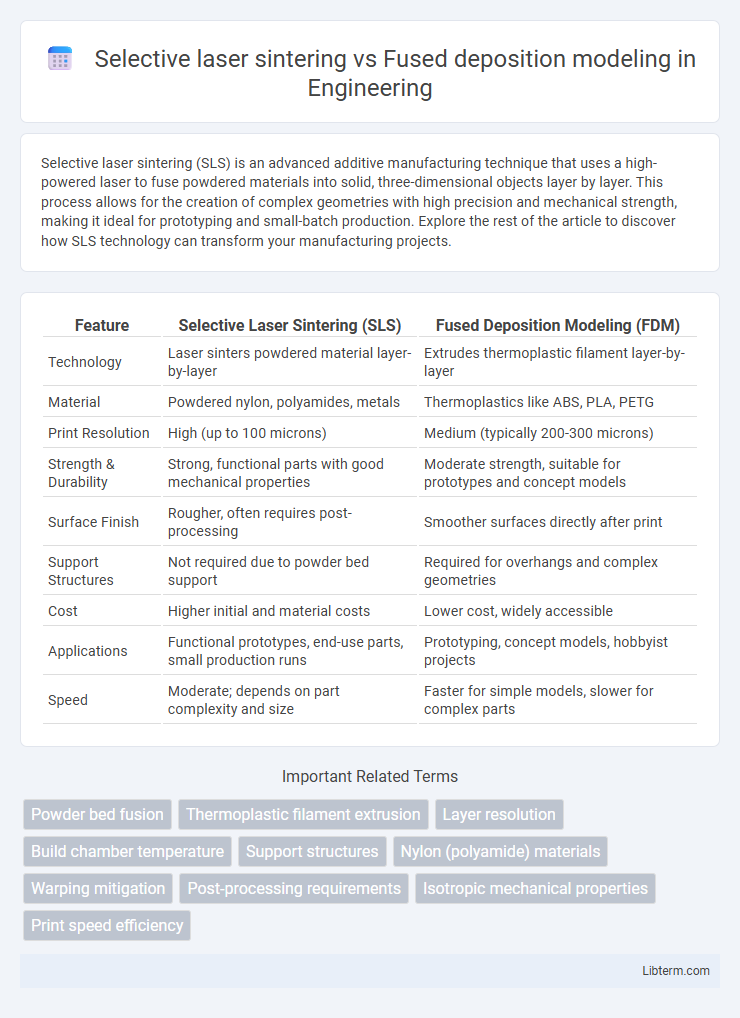

| Feature | Selective Laser Sintering (SLS) | Fused Deposition Modeling (FDM) |

|---|---|---|

| Technology | Laser sinters powdered material layer-by-layer | Extrudes thermoplastic filament layer-by-layer |

| Material | Powdered nylon, polyamides, metals | Thermoplastics like ABS, PLA, PETG |

| Print Resolution | High (up to 100 microns) | Medium (typically 200-300 microns) |

| Strength & Durability | Strong, functional parts with good mechanical properties | Moderate strength, suitable for prototypes and concept models |

| Surface Finish | Rougher, often requires post-processing | Smoother surfaces directly after print |

| Support Structures | Not required due to powder bed support | Required for overhangs and complex geometries |

| Cost | Higher initial and material costs | Lower cost, widely accessible |

| Applications | Functional prototypes, end-use parts, small production runs | Prototyping, concept models, hobbyist projects |

| Speed | Moderate; depends on part complexity and size | Faster for simple models, slower for complex parts |

Introduction to Additive Manufacturing Technologies

Selective laser sintering (SLS) and fused deposition modeling (FDM) are prominent additive manufacturing technologies widely used for rapid prototyping and production. SLS employs a high-powered laser to sinter powdered materials layer by layer, producing complex geometries with excellent mechanical properties and surface finish. FDM extrudes thermoplastic filaments through a heated nozzle to build parts layer by layer, offering cost-effective solutions and ease of use for functional prototypes and custom objects.

Overview of Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is an additive manufacturing process that uses a high-powered laser to fuse powdered materials, typically plastics, metals, or ceramics, layer by layer into a solid structure. This technique enables the production of complex geometries with high strength and excellent mechanical properties without the need for support structures. The precision of the laser and the variety of compatible materials make SLS ideal for rapid prototyping and functional end-use parts in industries such as aerospace, automotive, and healthcare.

Fundamentals of Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) operates by extruding thermoplastic filaments layer-by-layer through a heated nozzle, melting the material and depositing it precisely to build 3D objects. This additive manufacturing process relies on controlled temperature and nozzle movement driven by CAD data to form strong, functional parts with varying infill densities and layer resolutions. Unlike Selective Laser Sintering (SLS), which fuses powder using a laser, FDM's key advantage lies in its accessibility and ability to use a wide range of thermoplastics for prototyping and end-use applications.

Material Compatibility: SLS vs FDM

Selective laser sintering (SLS) supports a wide range of materials including nylon, polystyrene, and metal powders, enabling the production of highly durable and complex parts. Fused deposition modeling (FDM) primarily uses thermoplastics such as ABS, PLA, and PETG, which offer ease of use but limited mechanical properties compared to SLS materials. Material compatibility in SLS allows for functional prototypes and end-use parts with superior strength and heat resistance, while FDM suits rapid prototyping with cost-effective and widely available filaments.

Print Quality and Surface Finish Comparison

Selective laser sintering (SLS) offers superior print quality and surface finish compared to fused deposition modeling (FDM) due to its ability to fuse powdered materials with high precision, resulting in finer details and smoother surfaces. FDM prints often exhibit visible layer lines and require post-processing to improve texture, whereas SLS typically produces parts with consistent strength and minimal porosity directly from the printer. The enhanced resolution and material density of SLS contribute to its preferred use in functional prototypes and end-use parts demanding better aesthetic and mechanical properties.

Mechanical Properties of SLS and FDM Parts

Selective laser sintering (SLS) produces parts with superior mechanical properties, including higher tensile strength and better impact resistance, due to its ability to fuse powdered materials fully and create isotropic structures. In contrast, fused deposition modeling (FDM) parts often exhibit anisotropy and lower strength because of layer adhesion weaknesses and the use of thermoplastic filaments. SLS parts typically offer enhanced durability and thermal stability, making them more suitable for functional prototypes and end-use applications requiring high performance.

Design Flexibility and Geometric Complexity

Selective laser sintering (SLS) offers superior design flexibility and geometric complexity by allowing the creation of intricate, interlocking parts without support structures due to its powder bed fusion process. Fused deposition modeling (FDM) is more limited in handling complex geometries because it requires support materials for overhangs and less precision in fine detail reproduction. SLS excels in producing parts with intricate internal features and complex lattice structures, making it ideal for high-detail functional prototypes and end-use components.

Production Speed and Scalability

Selective laser sintering (SLS) offers faster production speeds than fused deposition modeling (FDM) due to its ability to sinter multiple parts simultaneously in a powder bed, significantly reducing build times for complex geometries. Scalability in SLS is enhanced by large build chambers that allow batch production, making it ideal for medium to large-scale manufacturing runs. In contrast, FDM's layer-by-layer extrusion process results in slower production speeds and limited scalability, as each part requires individual printing, making it more suitable for prototyping and small batch production.

Cost Analysis: SLS vs FDM

Selective laser sintering (SLS) typically involves higher upfront equipment costs and material expenses compared to fused deposition modeling (FDM), which uses more affordable thermoplastic filaments and has lower machine costs. Operating costs for SLS include costly powdered materials and post-processing, whereas FDM benefits from widely available, cheaper filaments and simpler maintenance. Despite the higher initial investment, SLS offers superior part strength and detail, making it cost-effective for complex, functional prototypes, while FDM excels in rapid, low-budget prototyping.

Best Use Cases for SLS and FDM

Selective laser sintering (SLS) excels in producing complex, durable, and high-resolution parts with intricate geometries and functional prototypes, making it ideal for aerospace, automotive, and medical applications requiring strong, heat-resistant materials. Fused deposition modeling (FDM) is best suited for rapid prototyping, cost-effective production of simple parts, and concept models in industries like consumer goods and education due to its accessibility and wide range of thermoplastic materials. SLS offers superior mechanical properties and surface finish, while FDM provides versatility and affordability for iterative design testing and low-volume manufacturing.

Selective laser sintering Infographic

libterm.com

libterm.com