Conveyor systems are essential for efficient material handling in various industries, streamlining the movement of goods and reducing manual labor. They improve productivity, enhance safety, and ensure consistent workflow in manufacturing and distribution centers. Discover how choosing the right conveyor system can optimize your operations by reading the rest of the article.

Table of Comparison

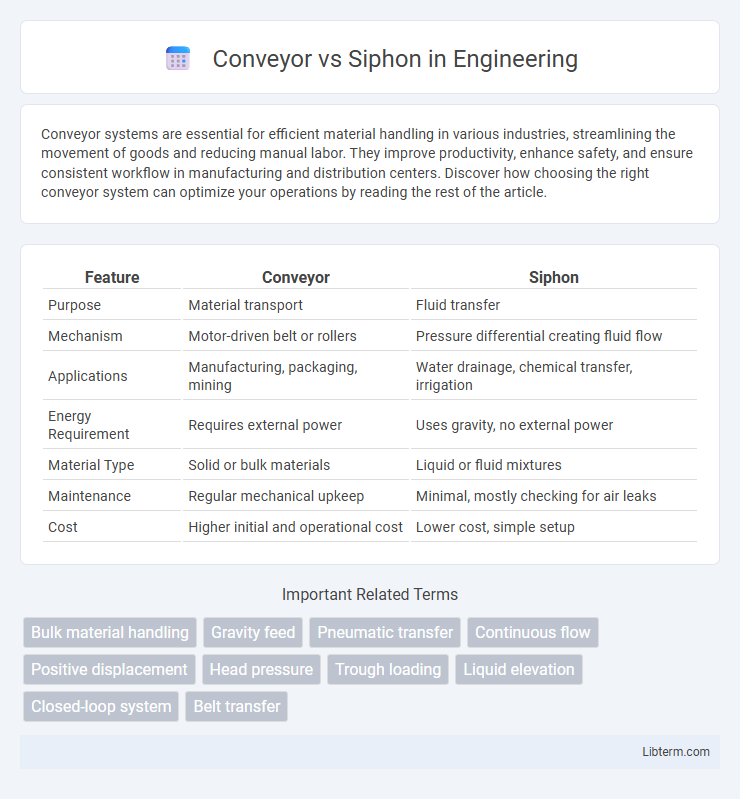

| Feature | Conveyor | Siphon |

|---|---|---|

| Purpose | Material transport | Fluid transfer |

| Mechanism | Motor-driven belt or rollers | Pressure differential creating fluid flow |

| Applications | Manufacturing, packaging, mining | Water drainage, chemical transfer, irrigation |

| Energy Requirement | Requires external power | Uses gravity, no external power |

| Material Type | Solid or bulk materials | Liquid or fluid mixtures |

| Maintenance | Regular mechanical upkeep | Minimal, mostly checking for air leaks |

| Cost | Higher initial and operational cost | Lower cost, simple setup |

Introduction to Conveyor and Siphon Systems

Conveyor systems are mechanical devices designed to transport materials efficiently across various industrial settings using belts, rollers, or chains, optimizing workflow and reducing manual labor. Siphon systems utilize fluid dynamics principles to transfer liquids from higher to lower elevations through a tube or pipe, relying on atmospheric pressure and gravity without requiring external power. Both systems serve distinct purposes in material and fluid movement, with conveyors excelling in solid transport and siphons ideal for liquid transfer applications.

How Conveyors Work: Principles and Mechanisms

Conveyors operate by using mechanical components such as belts, rollers, or chains to transport materials efficiently across different locations within industrial settings. The primary mechanism involves a continuous loop system powered by electric motors, which moves objects steadily and reduces manual handling. These systems can be adapted for various materials, providing customized speed, elevation, and load capacity to optimize workflow and increase productivity.

Understanding Siphon Systems: Basic Concepts

Siphon systems use atmospheric pressure and gravity to transfer liquids from one container to another, relying on a continuous flow maintained by a difference in liquid levels. Unlike conveyors that mechanically move solids or liquids, siphons function without external power, utilizing a tube or pipe filled with liquid to create a pressure differential. Proper installation and sealed tubing are critical to prevent air leaks, ensuring the siphon effect remains uninterrupted for efficient liquid transfer.

Key Differences Between Conveyor and Siphon Methods

Conveyor systems use mechanical components like belts or rollers to transport materials efficiently over distances, while siphon methods rely on gravity and fluid dynamics to move liquids through tubes or pipes. Conveyors are ideal for solid and bulk materials in industrial settings due to their controlled movement and speed, whereas siphons are commonly used for transferring liquids without external power sources. The main difference lies in the conveyor's active mechanical propulsion versus the siphon's passive reliance on pressure differences and elevation changes.

Efficiency Comparison: Conveyor vs Siphon

Conveyors offer higher energy efficiency by continuously transporting materials with minimal power consumption, especially in large-scale industrial settings. Siphons rely on gravity and atmospheric pressure, making them energy-efficient only when there is a suitable elevation difference but less effective for precise flow control. Overall, conveyors provide more consistent and controlled material movement, enhancing operational productivity compared to siphon systems.

Common Applications of Conveyor Systems

Conveyor systems are widely used in industries such as manufacturing, mining, and logistics for efficient material handling and transportation of goods over long distances or through complex pathways. They facilitate continuous movement of bulk materials, packages, and components in assembly lines, warehousing, and packaging operations. Unlike siphons, which rely on gravity to transfer fluids, conveyors offer customizable speed control and automation compatible with a variety of load types and weights.

Typical Uses of Siphon Technologies

Siphon technologies are primarily used for transferring liquids between containers at different heights without the need for pumps, making them ideal in irrigation systems, aquariums, and fuel transfer operations. Their ability to maintain a continuous flow based on gravitational force enables efficient drainage in sewage systems and rainwater harvesting setups. Siphons are also utilized in chemical processing and brewing industries where controlled fluid movement is crucial.

Pros and Cons: Conveyor Solutions

Conveyor solutions offer efficient material handling with high throughput and automation capabilities, making them ideal for continuous operations in manufacturing and logistics. They reduce manual labor and improve safety but often require significant upfront investment and maintenance. Limitations include inflexibility for complex routing and challenges handling fragile or irregular-shaped items.

Advantages and Limitations of Siphon Systems

Siphon systems offer the advantage of operating without external power sources, relying on gravity to move fluids, which reduces energy costs and enhances reliability in remote locations. However, limitations include sensitivity to air leaks and the requirement of maintaining a continuous fluid column, which can disrupt flow and necessitate careful installation and maintenance. Their efficiency diminishes over long distances or height differences, making them less suitable for industrial applications requiring consistent flow rates.

Choosing the Right System: Factors to Consider

Choosing between a conveyor and a siphon system depends on factors such as material type, distance, and elevation changes. Conveyors excel in handling heavy, bulky items over long distances with precise control, while siphons are ideal for transferring liquids or granular materials between elevation points with minimal energy consumption. Evaluating load weight, transfer speed, maintenance requirements, and energy efficiency ensures the right system aligns with operational needs.

Conveyor Infographic

libterm.com

libterm.com