Stamping is a precise metalworking process used to shape or cut metal sheets into specific forms by applying high-pressure force through a die. This technique offers high efficiency and consistency, making it ideal for producing complex parts in industries such as automotive, electronics, and aerospace. Explore the rest of the article to discover how stamping can enhance your manufacturing processes and product quality.

Table of Comparison

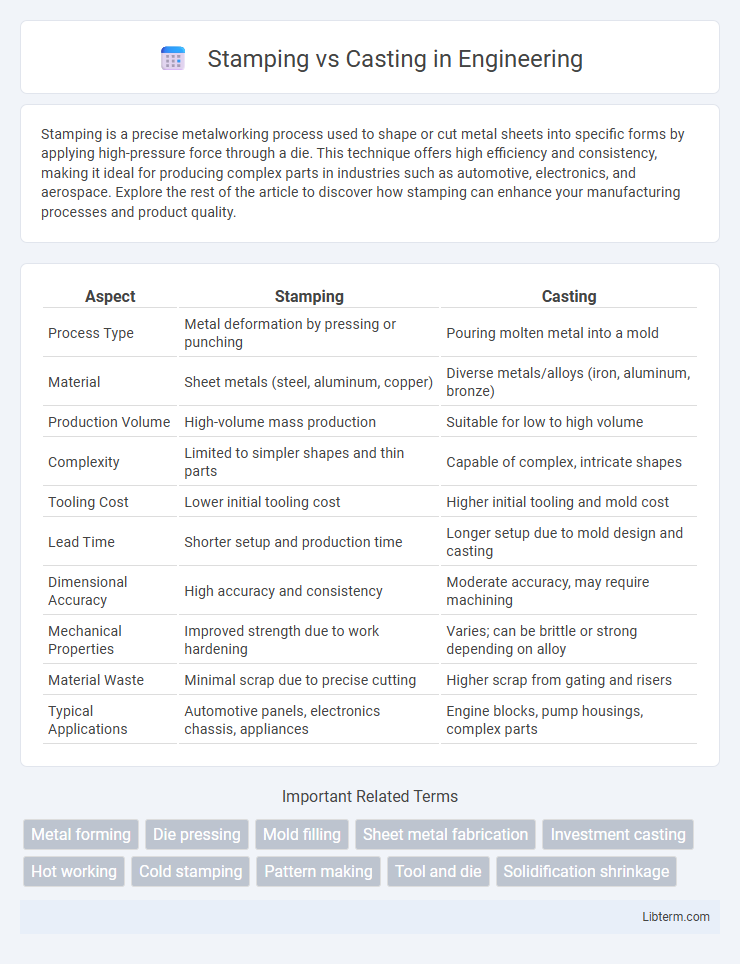

| Aspect | Stamping | Casting |

|---|---|---|

| Process Type | Metal deformation by pressing or punching | Pouring molten metal into a mold |

| Material | Sheet metals (steel, aluminum, copper) | Diverse metals/alloys (iron, aluminum, bronze) |

| Production Volume | High-volume mass production | Suitable for low to high volume |

| Complexity | Limited to simpler shapes and thin parts | Capable of complex, intricate shapes |

| Tooling Cost | Lower initial tooling cost | Higher initial tooling and mold cost |

| Lead Time | Shorter setup and production time | Longer setup due to mold design and casting |

| Dimensional Accuracy | High accuracy and consistency | Moderate accuracy, may require machining |

| Mechanical Properties | Improved strength due to work hardening | Varies; can be brittle or strong depending on alloy |

| Material Waste | Minimal scrap due to precise cutting | Higher scrap from gating and risers |

| Typical Applications | Automotive panels, electronics chassis, appliances | Engine blocks, pump housings, complex parts |

Introduction: Understanding Stamping and Casting

Stamping and casting are essential manufacturing processes used to shape metal parts with distinct techniques and applications. Stamping involves pressing metal sheets into specific shapes using dies, optimizing high-volume production with precision and speed. Casting entails pouring molten metal into molds, ideal for creating complex geometries and large components with detailed features.

Overview of Stamping in Manufacturing

Stamping in manufacturing involves shaping metal sheets through high-pressure presses using dies to create precise parts rapidly. This process offers advantages like high production speed, excellent repeatability, and minimal material waste, making it ideal for automotive and appliance industries. Stamping supports complex designs with tight tolerances, enhancing overall manufacturing efficiency and cost-effectiveness.

Overview of Casting Processes

Casting processes involve pouring molten metal into a mold where it solidifies into the desired shape, making it ideal for complex geometries and large components. Common casting methods include sand casting, die casting, and investment casting, each offering unique advantages in terms of surface finish, precision, and production volume. The versatility of casting allows for intricate designs and reduced material waste compared to stamping, which primarily relies on sheet metal deformation.

Key Differences Between Stamping and Casting

Stamping involves shaping metal sheets using high-pressure dies to create precise, thin, and consistent parts ideal for high-volume production, whereas casting melts metal to pour into molds, allowing complex shapes but potentially less dimensional accuracy. Stamping typically offers faster cycles and lower material waste, while casting enables the creation of larger, heavier components with intricate internal geometries. Durability and strength differ as stamped parts maintain metal grain structure, enhancing toughness, whereas cast parts may have internal porosity affecting mechanical properties.

Material Suitability: Stamping vs Casting

Stamping excels with ductile metals like aluminum, copper, and low-carbon steel, offering high precision for thin sheets and minimal material waste. Casting suits complex geometries and heavy metals such as iron, steel alloys, and non-ferrous metals, enabling intricate internal features and thicker wall sections. Material suitability depends on mechanical properties, dimensional accuracy, and production volume requirements for stamping or casting processes.

Cost Analysis: Which is More Economical?

Stamping offers lower per-unit costs for high-volume production due to faster cycle times and reduced material waste, making it economical for mass manufacturing. Casting involves higher initial tooling expenses and longer production cycles, but can be more cost-effective for complex geometries and smaller production runs. Evaluating factors such as production volume, part complexity, and material type is essential to determine the most economical choice between stamping and casting.

Production Volume Considerations

Stamping excels in high-volume production due to its rapid cycle times and cost-effective tooling, making it ideal for large-scale manufacturing of metal parts with consistent precision. Casting is better suited for low to medium production volumes where complex geometries are required, but tooling and setup costs are higher and cycle times are longer. Manufacturers typically choose stamping when producing thousands to millions of units, while casting is preferred for smaller batches or parts with intricate designs that are not feasible to stamp.

Strength and Quality of Finished Products

Stamping produces components with high strength due to work hardening during the deformation process, resulting in improved structural integrity and durability. Casting allows for complex shapes but may introduce porosity or shrinkage defects, affecting the quality and mechanical properties of the finished products. Precision and material density in stamping generally lead to superior surface finish and consistent dimensional accuracy compared to most casting methods.

Typical Applications and Industry Use Cases

Stamping is widely used in automotive manufacturing for producing high-volume, precise sheet metal parts such as body panels, brackets, and chassis components, benefiting industries like aerospace, electronics, and appliances due to its speed and cost-effectiveness. Casting is favored in industries requiring complex shapes and high strength, including heavy machinery, automotive engine blocks, and aerospace components, where materials like aluminum, iron, and steel are molded into durable, intricate parts. Both processes serve key roles in mass production and prototyping across sectors like construction, transportation, and consumer electronics, with stamping excelling in thin-metal fabrication and casting in producing robust, three-dimensional structures.

Choosing the Right Process for Your Project

Selecting between stamping and casting depends on factors such as production volume, material type, and design complexity. Stamping excels in high-volume manufacturing with thin metal sheets, offering precision and cost efficiency, while casting is ideal for complex shapes and thicker parts requiring detailed geometries. Evaluating part requirements, budget constraints, and lead times ensures optimal process choice for project success.

Stamping Infographic

libterm.com

libterm.com