Ceramic materials offer exceptional durability and heat resistance, making them ideal for cookware, tiles, and industrial applications. Their unique properties, such as hardness and electrical insulation, contribute to both aesthetic appeal and functionality in various uses. Discover how ceramics can enhance your everyday life by exploring the rest of this article.

Table of Comparison

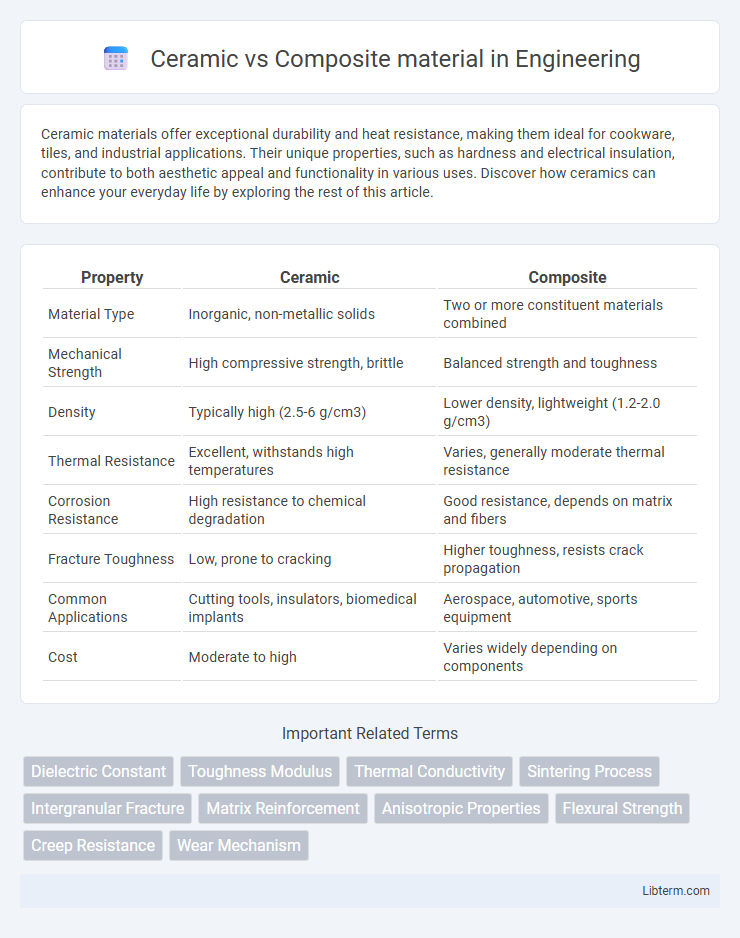

| Property | Ceramic | Composite |

|---|---|---|

| Material Type | Inorganic, non-metallic solids | Two or more constituent materials combined |

| Mechanical Strength | High compressive strength, brittle | Balanced strength and toughness |

| Density | Typically high (2.5-6 g/cm3) | Lower density, lightweight (1.2-2.0 g/cm3) |

| Thermal Resistance | Excellent, withstands high temperatures | Varies, generally moderate thermal resistance |

| Corrosion Resistance | High resistance to chemical degradation | Good resistance, depends on matrix and fibers |

| Fracture Toughness | Low, prone to cracking | Higher toughness, resists crack propagation |

| Common Applications | Cutting tools, insulators, biomedical implants | Aerospace, automotive, sports equipment |

| Cost | Moderate to high | Varies widely depending on components |

Introduction to Ceramic and Composite Materials

Ceramic materials are inorganic, non-metallic solids known for their high hardness, thermal stability, and resistance to wear and corrosion, widely used in applications like aerospace and medical implants. Composite materials combine two or more distinct phases, typically a matrix and reinforcement, to achieve superior mechanical properties such as increased strength-to-weight ratio and improved toughness. Both materials play critical roles in engineering, with ceramics favored for durability and composites for versatility and lightweight strength.

Definition and Composition

Ceramic materials are inorganic, non-metallic solids made from compounds of metal and non-metal elements, primarily oxides, carbides, and nitrides, known for their high hardness and thermal resistance. Composite materials consist of two or more distinct phases, typically a reinforcing fiber such as carbon or glass embedded in a polymer, metal, or ceramic matrix, designed to achieve superior mechanical properties. The composition of ceramics emphasizes crystalline or glassy structures, while composites rely on the synergy between matrix and reinforcement for tailored strength, toughness, and lightweight performance.

Unique Properties: Ceramics vs Composites

Ceramic materials boast exceptional hardness, high temperature resistance, and outstanding chemical stability, making them ideal for applications requiring wear resistance and thermal insulation. Composite materials combine multiple constituents, such as fibers and matrix, to achieve superior strength-to-weight ratios, enhanced toughness, and tailored mechanical properties for aerospace and automotive industries. The unique brittleness of ceramics contrasts with the ductility and impact resistance of composites, influencing their selection based on performance requirements.

Strength and Durability Comparison

Ceramic materials exhibit exceptional hardness and high compressive strength, making them ideal for applications requiring wear resistance and thermal stability. Composite materials offer superior toughness and impact resistance due to their combination of fibers and matrix, providing enhanced durability under dynamic stress conditions. The choice between ceramic and composite depends on the specific strength requirements and environmental exposure, with ceramics excelling in stiffness and composites in damage tolerance.

Weight and Density Differences

Ceramic materials typically exhibit higher density, ranging from 2.5 to 6 g/cm3, compared to composite materials, which generally have densities between 1.2 and 2 g/cm3, resulting in lighter weight structures. The lower density of composites, such as carbon fiber reinforced polymers, provides significant weight savings critical in aerospace and automotive applications. Increased weight efficiency in composites directly contributes to improved fuel efficiency and enhanced performance without compromising strength.

Thermal and Electrical Performance

Ceramic materials exhibit excellent thermal insulation due to their low thermal conductivity and high resistance to heat, making them suitable for high-temperature applications. Composite materials often provide tailored electrical properties, with the ability to combine conductive or insulating fibers and matrices to achieve desired electrical performance. While ceramics are generally electrical insulators, composites can be engineered to be either conductive or insulating, offering more versatility in electrical applications.

Applications in Industry

Ceramic materials are widely used in high-temperature applications such as aerospace components, cutting tools, and biomedical implants due to their excellent heat resistance and hardness. Composite materials dominate the automotive and construction industries by offering enhanced strength-to-weight ratios, corrosion resistance, and design flexibility. Both materials provide critical solutions tailored to specific industrial needs, optimizing performance and durability under varying operational conditions.

Cost Efficiency and Availability

Ceramic materials generally exhibit higher initial costs due to complex manufacturing processes and limited availability, impacting overall cost efficiency. Composite materials offer greater cost efficiency through lower production expenses and widespread availability, making them suitable for mass-market applications. The economic advantage of composites is enhanced by their adaptability and easier sourcing compared to specialized ceramics.

Environmental Impact and Sustainability

Ceramic materials exhibit high durability and inertness, contributing to minimal environmental degradation and enhanced recyclability compared to composite materials, which often contain synthetic polymers with limited biodegradability. The production of ceramics generally requires less energy and releases fewer greenhouse gases, while composites involve complex manufacturing processes with higher carbon footprints and challenges in recycling due to mixed material components. Sustainable development prioritizes ceramics for their potential in reducing waste and promoting long-term resource efficiency in various industrial applications.

Choosing the Right Material for Your Needs

Ceramic materials offer exceptional hardness and heat resistance, making them ideal for high-temperature applications and wear-resistant surfaces. Composite materials combine multiple elements to provide enhanced strength, flexibility, and corrosion resistance, suitable for lightweight structural applications. Selecting the right material depends on factors such as mechanical stress, thermal stability, environmental exposure, and cost-efficiency to ensure optimal performance and durability.

Ceramic Infographic

libterm.com

libterm.com