Stress distribution plays a crucial role in structural engineering, determining how forces are spread across materials to prevent failure. Understanding these patterns helps optimize design, enhance durability, and ensure safety in construction and mechanical applications. Explore the rest of this article to learn how mastering stress distribution can improve your projects.

Table of Comparison

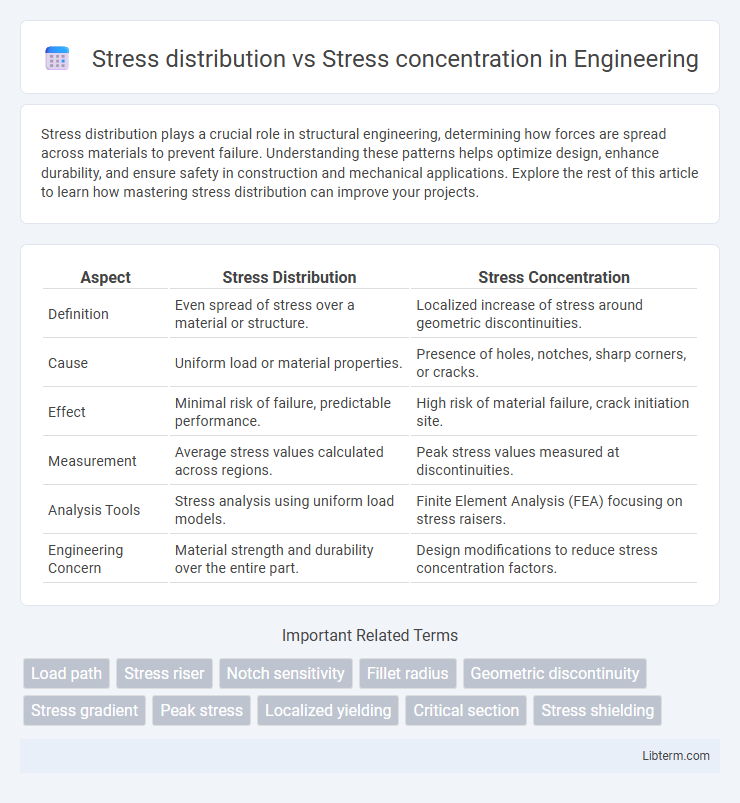

| Aspect | Stress Distribution | Stress Concentration |

|---|---|---|

| Definition | Even spread of stress over a material or structure. | Localized increase of stress around geometric discontinuities. |

| Cause | Uniform load or material properties. | Presence of holes, notches, sharp corners, or cracks. |

| Effect | Minimal risk of failure, predictable performance. | High risk of material failure, crack initiation site. |

| Measurement | Average stress values calculated across regions. | Peak stress values measured at discontinuities. |

| Analysis Tools | Stress analysis using uniform load models. | Finite Element Analysis (FEA) focusing on stress raisers. |

| Engineering Concern | Material strength and durability over the entire part. | Design modifications to reduce stress concentration factors. |

Introduction to Stress Distribution and Stress Concentration

Stress distribution refers to the way stress is spread over a material or structure under load, maintaining relatively uniform intensity across the surface or volume. In contrast, stress concentration occurs at specific points, such as holes, notches, or abrupt changes in geometry, where stress levels significantly exceed the average stress in the surrounding area. Understanding both stress distribution and stress concentration is critical for predicting material failure and optimizing designs to enhance structural integrity.

Defining Stress Distribution

Stress distribution refers to the variation of stress values over a material or structural component under load, indicating how internal forces are spread throughout its volume or surface. It is a continuous, often predictable pattern influenced by geometry, material properties, and loading conditions. Understanding stress distribution is essential for designing components that avoid localized weaknesses and ensure uniform load-bearing capacity.

Understanding Stress Concentration

Stress concentration refers to localized increases in stress around discontinuities such as holes, notches, or sharp corners in a material, significantly exceeding the nominal stress. Unlike uniform stress distribution, stress concentration leads to critical points where failure or crack initiation is more likely, especially under cyclic loading conditions. Understanding stress concentration involves analyzing stress raisers using factors like the stress concentration factor (Kt), enabling engineers to design components that minimize failure risks by optimizing geometry and material properties.

Key Differences: Distribution vs. Concentration

Stress distribution refers to the spread of stress over a material or structure, ensuring load is shared relatively evenly across the surface or volume. Stress concentration occurs at specific points or regions where stress is significantly higher due to geometric discontinuities such as holes, notches, or sharp corners. The key difference lies in the uniformity of stress presence: distribution spreads stress broadly, while concentration localizes it intensely, potentially leading to failure.

Common Causes of Stress Concentration

Stress concentration occurs due to abrupt changes in geometry such as notches, holes, sharp corners, and keyways, which amplify local stresses compared to the nominal stress distribution. Material defects like inclusions, cracks, and voids also act as common causes of stress concentration by disrupting the uniform stress flow. Understanding these factors is essential to predict failure points and improve design by reducing localized stress risers in critical structural components.

Effects of Stress Distribution in Engineering Design

Stress distribution in engineering design refers to the uniform allocation of forces across a material or structure, reducing the likelihood of localized failures. Properly managed stress distribution improves durability by minimizing weak points where stress concentration--intense localized stress--might otherwise cause cracks or fractures. Utilizing techniques such as fillets, gradual cross-sectional changes, and material selection enhances stress distribution, optimizing overall structural performance and safety.

Methods to Identify Stress Concentrations

Stress concentrations are localized increases in stress typically found near geometric discontinuities like holes, notches, or sharp corners, whereas stress distribution refers to the overall spread of stress within a material. Methods to identify stress concentrations include analytical techniques based on elasticity theory, numerical approaches such as finite element analysis (FEA), and experimental methods like photoelasticity or strain gauge measurements. Accurate identification of stress concentration zones is crucial for predicting failure points and optimizing structural design.

Techniques to Minimize Stress Concentration

Stress concentration occurs at geometric discontinuities such as notches, holes, or sharp corners, causing localized increase in stress compared to the average stress distribution in a material. Techniques to minimize stress concentration include adding fillets or rounded corners, using gradual transitions in cross-section, and employing surface treatments like shot peening to enhance fatigue strength. Optimizing structural design through finite element analysis (FEA) helps identify critical stress points and refine geometry to ensure more uniform stress distribution.

Real-World Examples and Case Studies

Stress distribution refers to the even spread of stress throughout a material, as seen in cylindrical pressure vessels where internal pressure causes uniform hoop stress minimizing failure risks. Stress concentration occurs at geometric discontinuities like holes or notches, exemplified by cracks initiating at bolt holes in aircraft fuselages leading to catastrophic failures in historical case studies. Engineering designs use finite element analysis to predict and mitigate stress concentrations, improving durability in bridges and automotive components by optimizing shape and material selection.

Conclusion: Balancing Stress in Structural Systems

Stress distribution refers to the even spread of stress across a structural component, minimizing weak points and enhancing overall durability. Stress concentration occurs when stress accumulates at specific locations, such as holes, notches, or sharp corners, increasing the risk of material failure. Balancing these phenomena in structural systems requires optimizing design features to reduce stress risers and promote uniform load transfer, thereby improving performance and longevity.

Stress distribution Infographic

libterm.com

libterm.com