Setup time significantly impacts overall productivity by determining how quickly a process can begin after a changeover or maintenance. Reducing setup time minimizes downtime, increases operational efficiency, and enhances your workflow, leading to faster project completion and cost savings. Explore the rest of the article to discover effective strategies for optimizing your setup time.

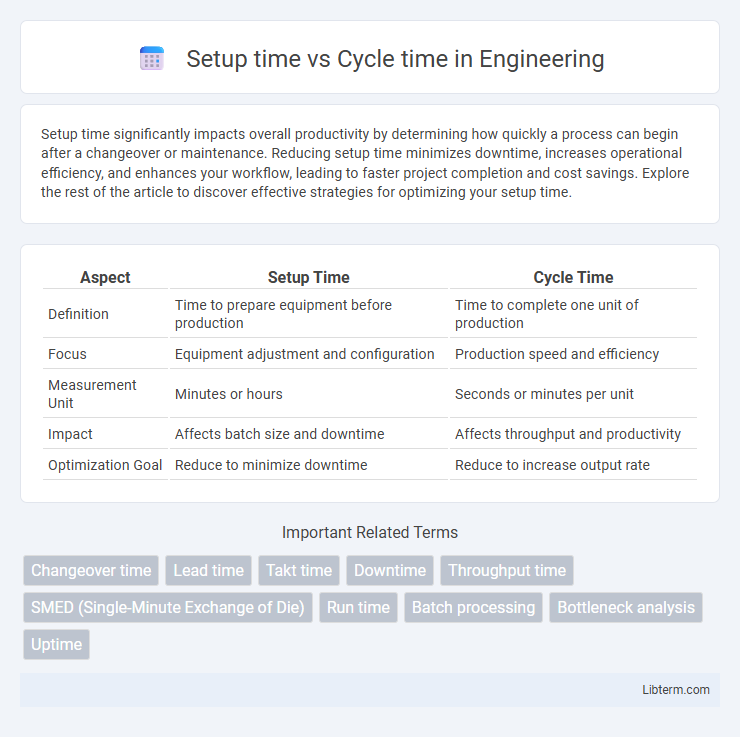

Table of Comparison

| Aspect | Setup Time | Cycle Time |

|---|---|---|

| Definition | Time to prepare equipment before production | Time to complete one unit of production |

| Focus | Equipment adjustment and configuration | Production speed and efficiency |

| Measurement Unit | Minutes or hours | Seconds or minutes per unit |

| Impact | Affects batch size and downtime | Affects throughput and productivity |

| Optimization Goal | Reduce to minimize downtime | Reduce to increase output rate |

Introduction to Setup Time and Cycle Time

Setup time refers to the duration required to prepare equipment or processes before production begins, including tasks such as tool changes and calibrations. Cycle time represents the total time taken to complete one unit of production, encompassing both processing and any wait periods. Understanding the distinction between setup time and cycle time is crucial for optimizing manufacturing efficiency and reducing overall production lead time.

Definitions: What is Setup Time?

Setup time refers to the duration required to prepare a machine or production process before starting actual manufacturing, including tasks like equipment adjustments, tool changes, and calibration. It directly impacts manufacturing efficiency by determining how quickly a system can transition between different production batches. Minimizing setup time is crucial for reducing downtime and enhancing overall throughput in lean manufacturing environments.

Definitions: What is Cycle Time?

Cycle time refers to the total time taken to complete one full cycle of a manufacturing or production process, from the start of one unit to the start of the next. It encompasses all operations, including processing, waiting, and movement times, directly impacting production efficiency and throughput. Unlike setup time, which is the initial preparation before production begins, cycle time measures the ongoing pace of production activity.

Key Differences Between Setup Time and Cycle Time

Setup time refers to the duration required to prepare equipment or machines for a specific production process before actual manufacturing begins. Cycle time measures the total time taken to complete one full production cycle, from the start of the process to the finished product. Key differences include setup time being a non-value-added interval focused on changeover, while cycle time encompasses both setup and operational phases, directly impacting production efficiency and throughput.

Importance of Setup Time in Manufacturing

Setup time directly impacts manufacturing efficiency by determining how quickly machines can transition between production runs, influencing overall equipment utilization and reducing downtime. Minimizing setup time is crucial for just-in-time production and flexible manufacturing systems, enabling faster response to market demand and customization. Efficient setup time management contributes to lower production costs, higher throughput, and improved competitiveness in manufacturing operations.

Impact of Cycle Time on Productivity

Cycle time directly influences productivity by determining the speed at which products are completed and delivered to customers. Shorter cycle times enhance throughput, reduce work-in-progress inventory, and enable faster response to market demands. Efficient management of cycle time minimizes bottlenecks, optimizes resource utilization, and drives overall operational efficiency in manufacturing and service industries.

Strategies to Reduce Setup Time

Reducing setup time is critical for improving overall manufacturing efficiency and can be achieved through strategies such as implementing Single-Minute Exchange of Dies (SMED), standardizing setup procedures, and investing in quick-release mechanisms or modular tooling. SMED techniques focus on separating internal and external setup tasks to perform adjustments while the machine is running, significantly minimizing downtime. Streamlined training and continuous process optimization also contribute to faster changeovers, directly impacting cycle time and increasing production throughput.

Techniques to Optimize Cycle Time

Reducing cycle time involves techniques such as implementing lean manufacturing principles, utilizing process automation, and applying continuous improvement methods like Six Sigma to identify bottlenecks. Standardizing work procedures and reducing batch sizes also streamline each production phase, minimizing idle time and enhancing throughput. Efficient scheduling and preventive maintenance ensure machines and labor resources operate without interruption, further optimizing cycle time.

Real-World Examples: Setup Time vs Cycle Time

In manufacturing, setup time refers to the duration required to prepare equipment or processes before production begins, such as changing machine tools or calibrating devices, while cycle time measures the actual time taken to produce one unit from start to finish. For example, in an automotive assembly line, setup time involves arranging robotic arms and fixtures for a specific vehicle model, typically taking several hours, whereas cycle time is measured in minutes to assemble each car component. Reducing setup time through techniques like SMED (Single-Minute Exchange of Dies) directly impacts overall efficiency by allowing more production cycles within the same timeframe.

Conclusion: Balancing Setup Time and Cycle Time for Efficiency

Balancing setup time and cycle time is critical for optimizing manufacturing efficiency and minimizing production costs. Reducing setup time accelerates machine readiness and increases flexibility, while minimizing cycle time enhances throughput and product output. An ideal balance tailors strategies to specific production goals, ensuring operational agility without compromising quality or capacity.

Setup time Infographic

libterm.com

libterm.com