Sheet lamination is an additive manufacturing process that builds objects by stacking and bonding thin layers of material, such as paper, plastic, or metal sheets. This technique offers rapid production, cost-effectiveness, and the ability to create complex geometries with fine detail. Discover how sheet lamination can transform your manufacturing projects by reading the rest of the article.

Table of Comparison

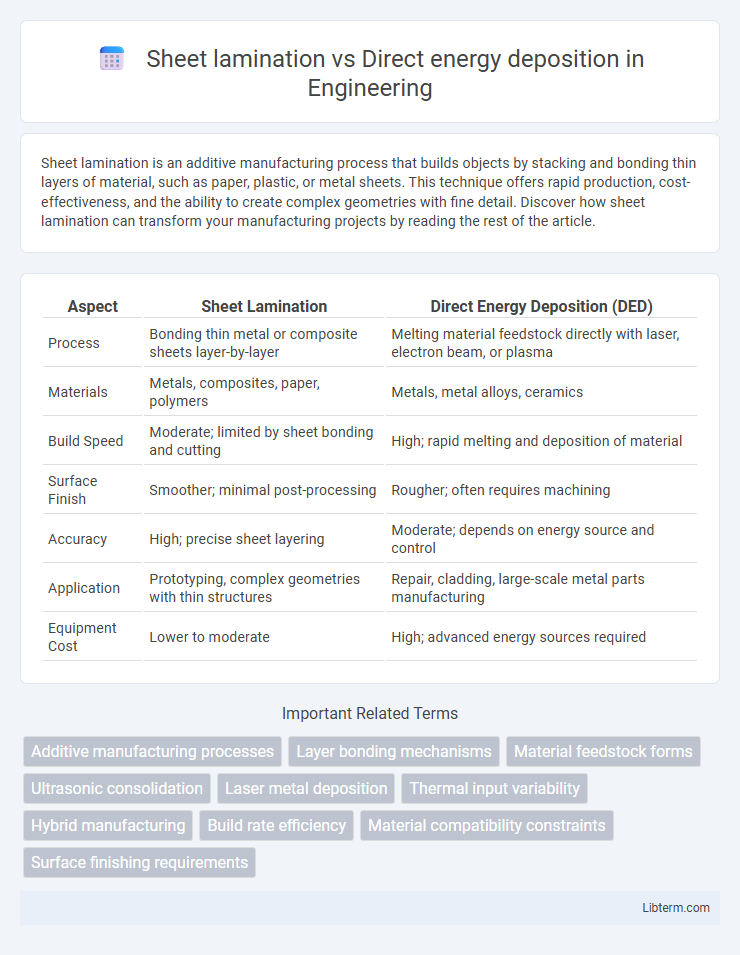

| Aspect | Sheet Lamination | Direct Energy Deposition (DED) |

|---|---|---|

| Process | Bonding thin metal or composite sheets layer-by-layer | Melting material feedstock directly with laser, electron beam, or plasma |

| Materials | Metals, composites, paper, polymers | Metals, metal alloys, ceramics |

| Build Speed | Moderate; limited by sheet bonding and cutting | High; rapid melting and deposition of material |

| Surface Finish | Smoother; minimal post-processing | Rougher; often requires machining |

| Accuracy | High; precise sheet layering | Moderate; depends on energy source and control |

| Application | Prototyping, complex geometries with thin structures | Repair, cladding, large-scale metal parts manufacturing |

| Equipment Cost | Lower to moderate | High; advanced energy sources required |

Introduction to Sheet Lamination and Direct Energy Deposition

Sheet lamination builds 3D objects by bonding and stacking thin material sheets, utilizing techniques such as ultrasonic welding or adhesive bonding, suitable for metals, plastics, and ceramics. Direct energy deposition employs focused energy sources like lasers or electron beams to melt materials as they are deposited, enabling precise repairs and complex geometries with metals and metal matrix composites. Both technologies excel in additive manufacturing, with sheet lamination emphasizing layered sheet bonding and direct energy deposition focusing on material melting during fabrication.

Process Overview: Sheet Lamination Explained

Sheet lamination involves stacking and bonding thin metal or composite sheets layer by layer using adhesives or ultrasonic welding, enabling rapid production of complex geometries with minimal material waste. This process differs fundamentally from Direct Energy Deposition (DED), which uses focused thermal energy to melt materials as they are deposited, allowing for real-time material addition and repair. Sheet lamination offers precise layer control and cost efficiency, particularly suited for prototypes and parts requiring multiple material combinations.

Understanding Direct Energy Deposition Techniques

Direct Energy Deposition (DED) techniques utilize focused thermal energy sources such as lasers or electron beams to deposit material precisely layer by layer, enabling complex geometries and repairs on existing components. Unlike sheet lamination, which stacks and bonds sheets of material, DED allows for metallurgical bonding through melting and solidifying powders or wires, enhancing mechanical properties and material density. Key applications of DED include aerospace part restoration, turbine blade repair, and fabrication of high-performance metal components with minimal waste.

Materials Compatibility in Both Methods

Sheet lamination supports a wide range of compatible materials including metals, plastics, and ceramics due to its layer-by-layer bonding process. Direct energy deposition excels in processing high-performance alloys and metals such as titanium, nickel-based superalloys, and stainless steel, benefiting from precise control of heat input and powder or wire feedstock. Material compatibility in sheet lamination is limited by adhesive or bonding methods, while direct energy deposition offers superior versatility for repairing or adding features to existing metal parts.

Precision and Accuracy Comparison

Sheet lamination offers high accuracy through layer-by-layer stacking and precise cutting, making it ideal for creating detailed geometries with consistent dimensional control. Direct energy deposition achieves greater precision in material placement by using focused energy sources like lasers or electron beams, enabling fine-tuned deposition and repair on complex surfaces. While sheet lamination excels in uniform layer accuracy, direct energy deposition provides superior localized accuracy and adaptability for customized part refinement.

Build Speed and Efficiency Factors

Sheet lamination offers faster build speeds due to its layer-by-layer stacking of pre-formed sheets, minimizing material waste and reducing post-processing time. Direct energy deposition, while slower due to its point-by-point material melting process, provides greater efficiency in repairing or adding material to existing parts, optimizing material usage for complex geometries. Build speed in sheet lamination excels in volume production, whereas direct energy deposition prioritizes precision and material efficiency in tailored or repair applications.

Surface Finish and Post-Processing Requirements

Sheet lamination typically delivers smoother surface finishes due to its layer-by-layer bonding of thin sheets, reducing the need for extensive post-processing compared to direct energy deposition. Direct energy deposition often results in rougher surfaces with visible striations, necessitating additional machining or polishing to achieve desired tolerances and aesthetics. Post-processing requirements for sheet lamination are generally lower, making it more suitable for applications demanding fine surface quality with minimal finishing.

Cost Analysis: Sheet Lamination vs Direct Energy Deposition

Sheet lamination typically offers lower initial equipment costs and faster production times, making it cost-effective for prototyping and low-volume manufacturing. Direct energy deposition incurs higher operational expenses due to its complex machinery and energy consumption but provides advantages in repair applications and material efficiency. Cost analysis indicates sheet lamination is preferable for economical upfront investment, while direct energy deposition justifies its expense through enhanced precision and versatility.

Typical Applications and Industry Adoption

Sheet lamination is commonly used in rapid prototyping and low-cost manufacturing for creating complex geometries with materials like paper, metal, or plastic, favored in industries such as automotive and aerospace for concept models and tooling. Direct energy deposition excels in repairing and adding features to existing components, commonly applied in aerospace, defense, and oil & gas sectors for part refurbishment, complex part manufacturing, and material customization. Industry adoption of sheet lamination remains niche due to limited mechanical properties, whereas direct energy deposition sees broader use due to its ability to work with high-value metals and alloys in critical applications.

Choosing the Right Technique: Key Considerations

Sheet lamination excels in cost-effectiveness and material variety, ideal for rapid prototyping and low-strength applications, while direct energy deposition offers superior precision and metallurgical control for complex, high-strength parts. Key considerations include part complexity, mechanical property requirements, production speed, and post-processing needs. Evaluating these factors ensures selection of the optimal additive manufacturing technique tailored to specific engineering goals.

Sheet lamination Infographic

libterm.com

libterm.com